Two-site polishing machine

A polishing machine and two-station technology, applied in the direction of polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of small contact surface, low work efficiency, poor brightness of polished surface, etc., and increase the contact area , Improve work efficiency, and stabilize the polishing state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

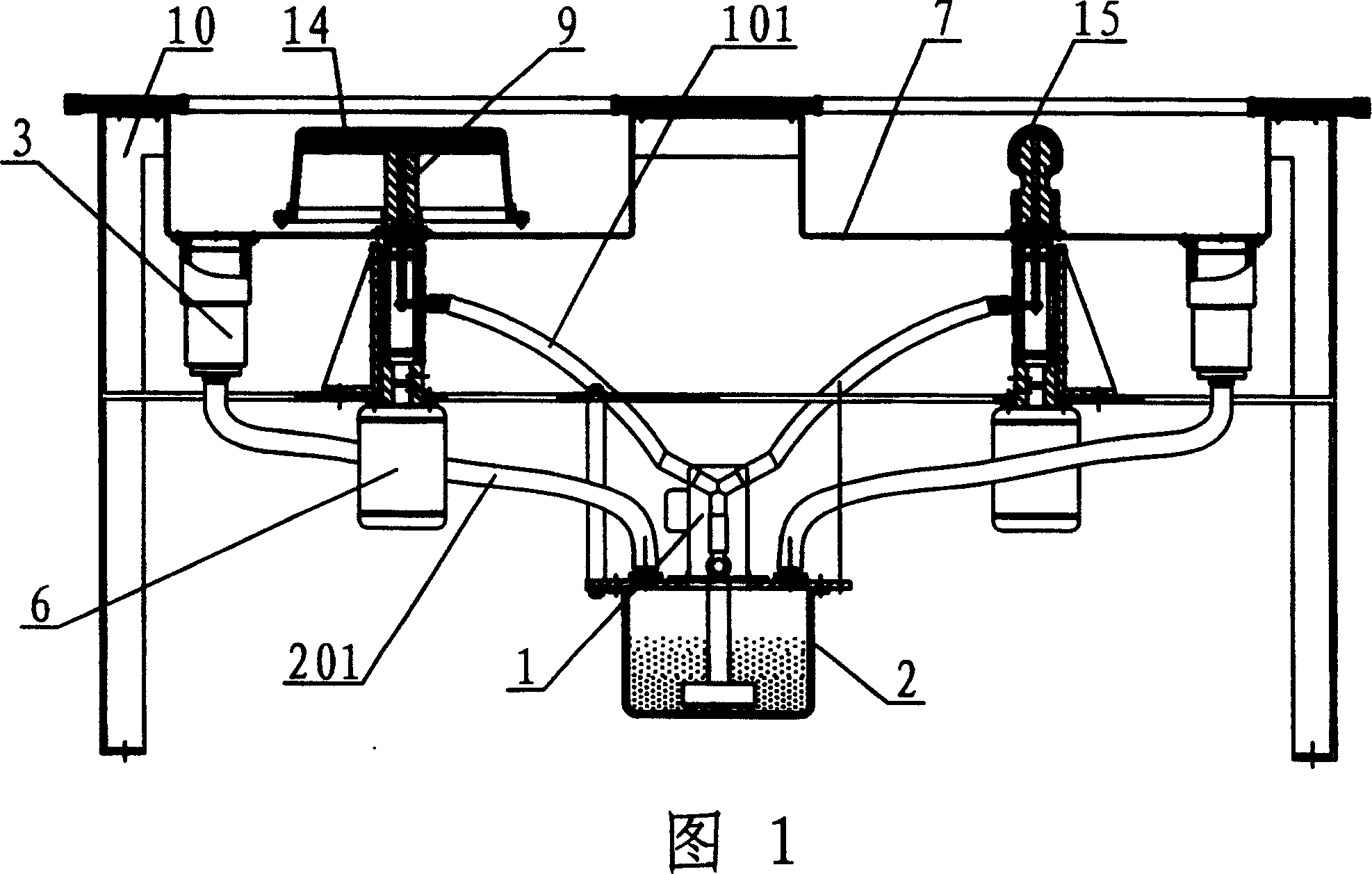

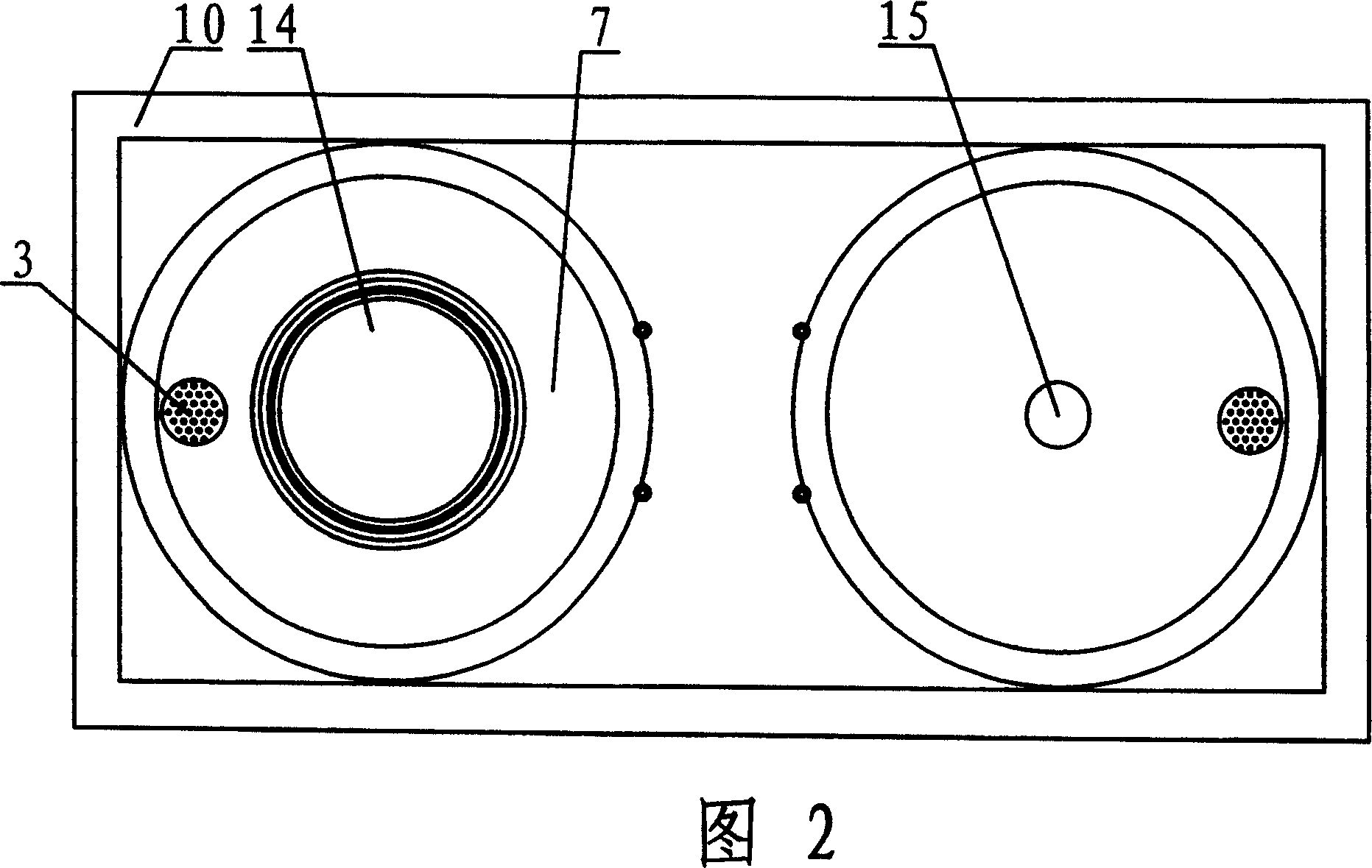

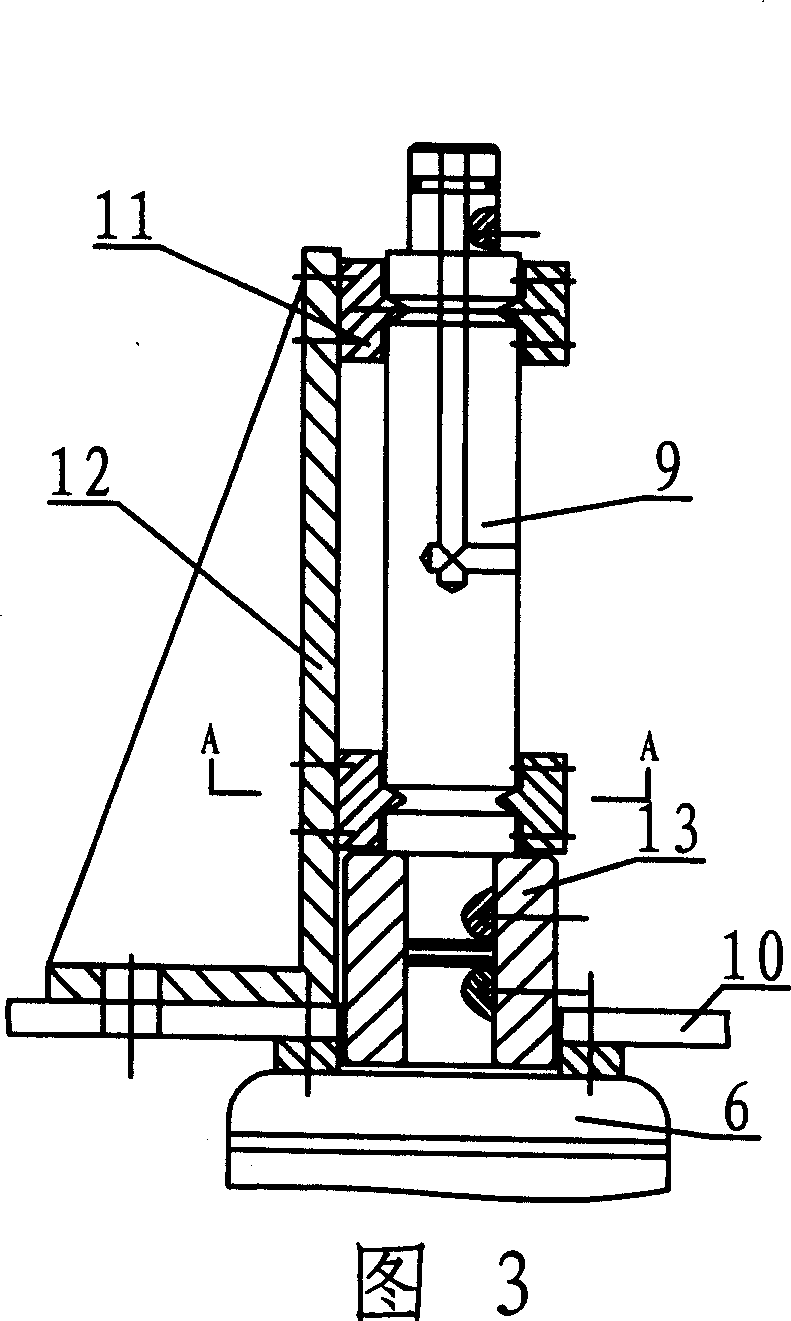

[0047] Polishing machine embodiment 1 of the present invention as shown in Fig. 1, 2, it has two stations, promptly it has flat disc 14, two polishing discs of cam disc 15, and two polishing discs are driven by two powers respectively. Device——motor 6 drives. The polishing machine includes: a frame 10, a flat wheel disc 14, a cam disc 15, two vertically installed motors 6, an automatic liquid supply system for providing polishing liquid to the polishing wheel disc, and a polishing liquid recovery system. The polishing disc is arranged on the frame 10. As shown in Figure 9, the polishing liquid recovery system includes two upwardly opening polishing liquid collection vessels 7, the flat wheel disc 14 and the cam disc 15 are respectively arranged in the two collection vessels 7, and the bottom of each collection vessel 7 passes through the pipeline 201 respectively. It communicates with the liquid storage tank 2; the center of the bottom of each collection vessel 7 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com