Fixing and moving mechanism for side wall polishing mechanism of bent hardware

A technology of polishing mechanism and moving mechanism, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., which can solve the problems of manual polishing and parts clamping and fixing, and achieve convenient and automatic The effect of polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

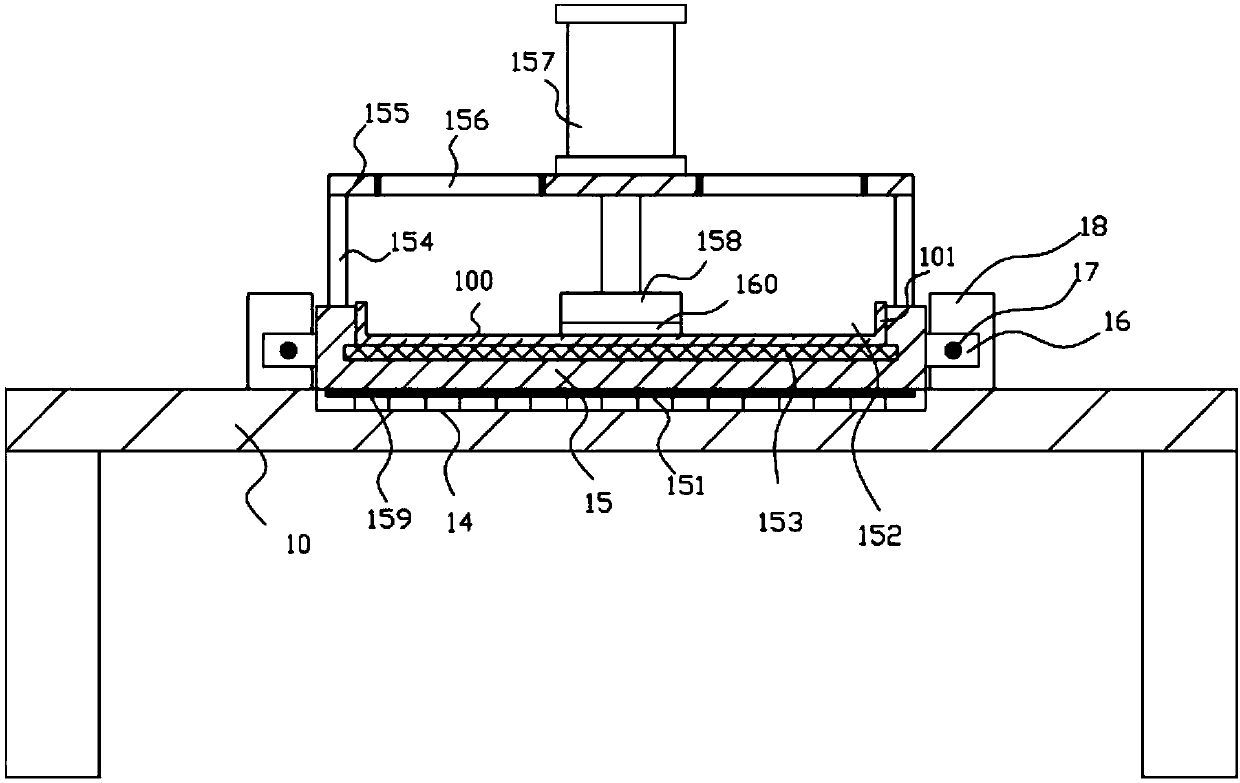

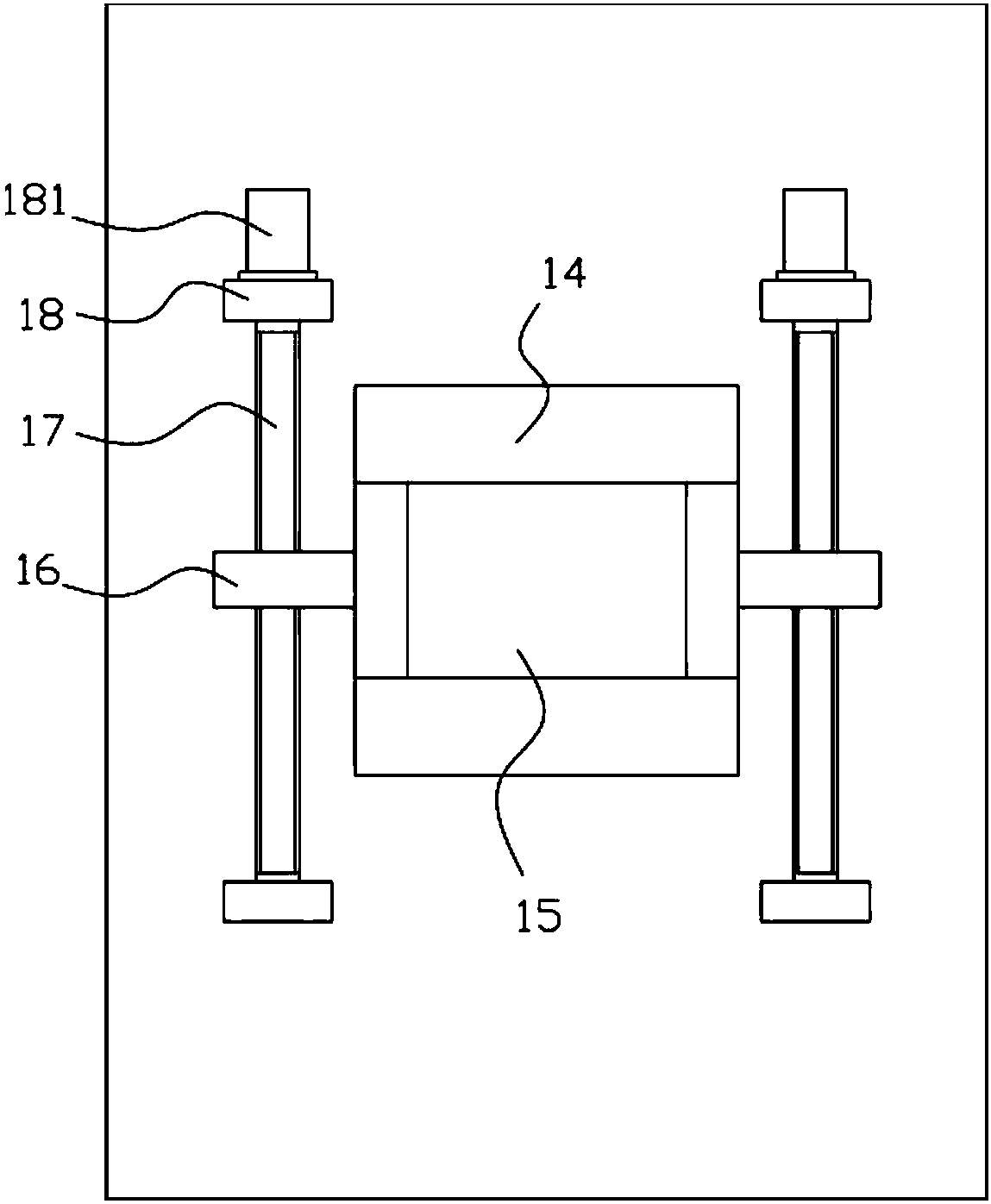

[0014] Example: see Figure 1 to Figure 2 As shown, a fixed moving mechanism for the side wall polishing mechanism of bending hardware includes a frame 10, the middle top surface of the top plate of the frame 10 is provided with a fixed block 15, and the middle part of the top surface of the fixed block 15 has a Groove 152, the installation groove that the bottom surface of groove 152 has is fixed with electromagnet plate 153, the workpiece 100 to be processed is adsorbed on the electromagnet plate 153, the bending portion that the both sides top surface of workpiece 100 to be processed has 101 is placed close to the inner side wall of the groove 152, the two sides of the fixed block 15 are fixed with the moving block 16, the moving block 16 is screwed in the horizontal screw rod 17, and the two ends of the horizontal screw rod 17 are hinged on the top of the top plate of the frame 10 On the corresponding support plate 18 that the front and the rear of both sides of the face a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com