Chamfering grinder

A grinding machine and chamfering technology, applied in grinding machines, machine tools suitable for grinding workpiece edges, grinding/polishing equipment, etc., can solve the problems of high cost, low production efficiency, complicated steps, etc., and achieve low manufacturing costs. , Improve the processing efficiency, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

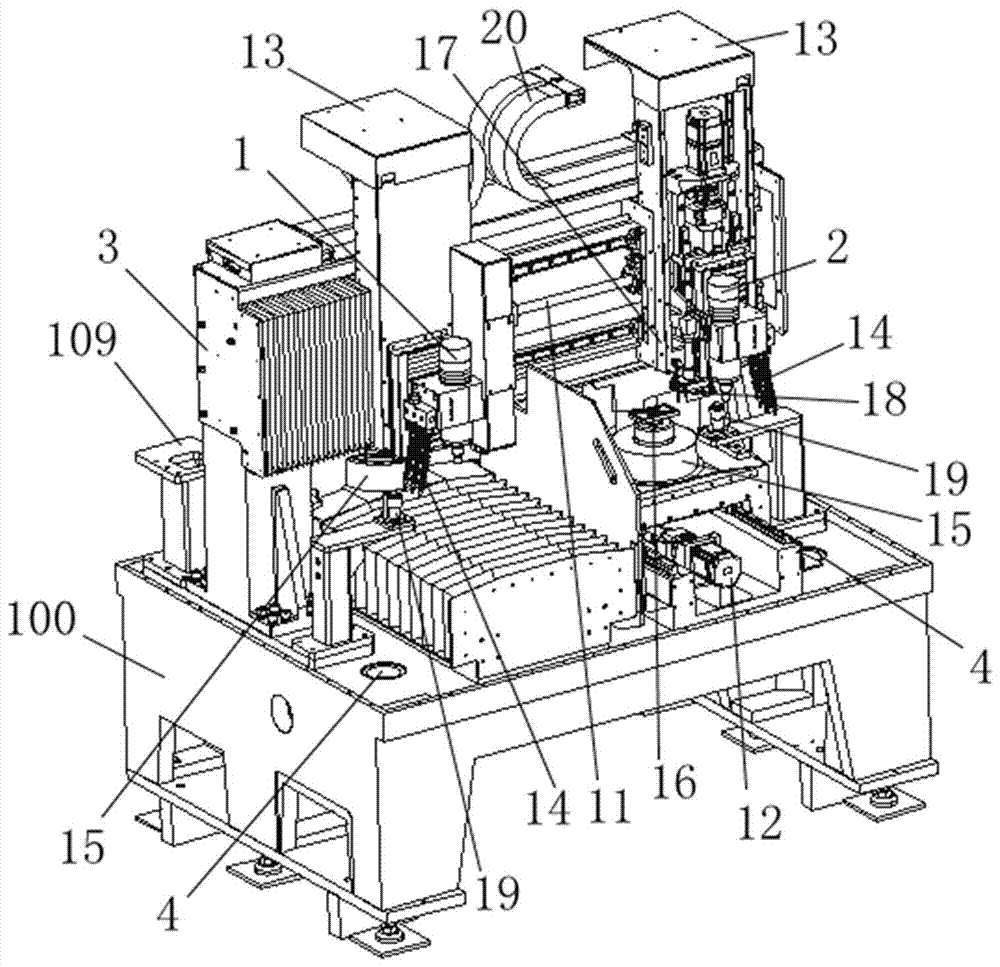

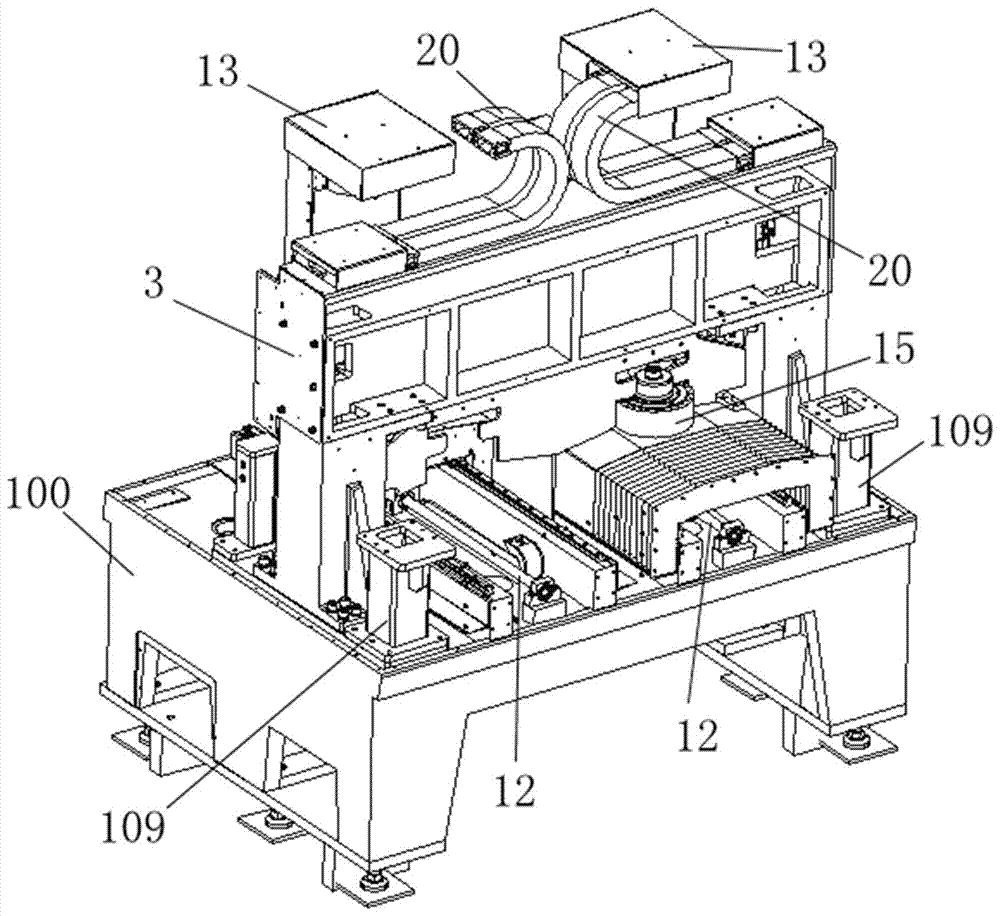

[0020] The content of the present invention will be further described below in conjunction with the accompanying drawings.

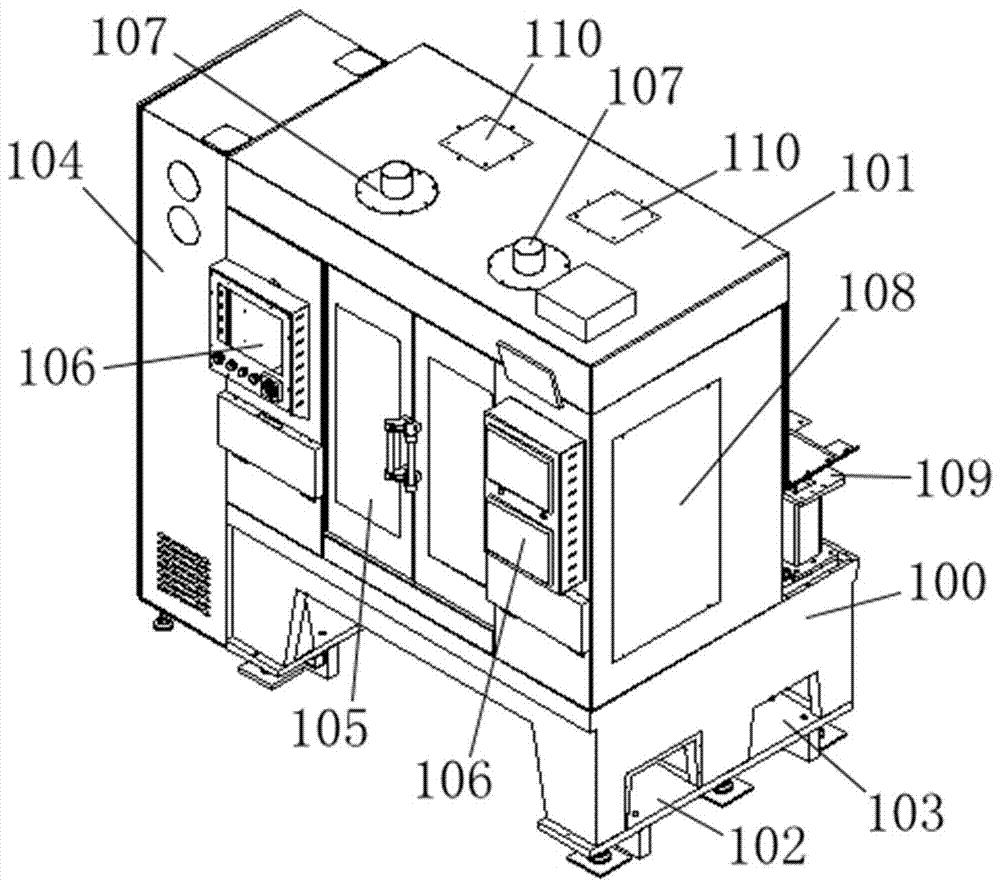

[0021] Such as figure 1 As shown, the chamfering grinder of the present invention is used for edge grinding and chamfering of liquid crystal panels. The chamfering grinder includes a base 100, and the base 100 can be a cast iron base; An upper machine cover 101 is arranged on the upper surface, a water inlet and outlet hole 102 and a process hole 103 are arranged at the bottom of the base 100, and a power distribution cabinet 104 is also arranged on the left side of the base 100; wherein, the water inlet and outlet hole 102 is for external The pipeline channel from the centrifuge to the clear water TANK at the bottom of the chamfering grinder, the process hole 103 can reduce the weight and can provide a channel for the upstream and downstream machines to pass through.

[0022] exist figure 1 Among them, an openable sliding door 105 is provided on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com