variable capacity supercharger

A supercharger and variable technology, applied in the direction of machines/engines, engine manufacturing, combustion engines, etc., to achieve the effect of simplifying the structure and improving the ease of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

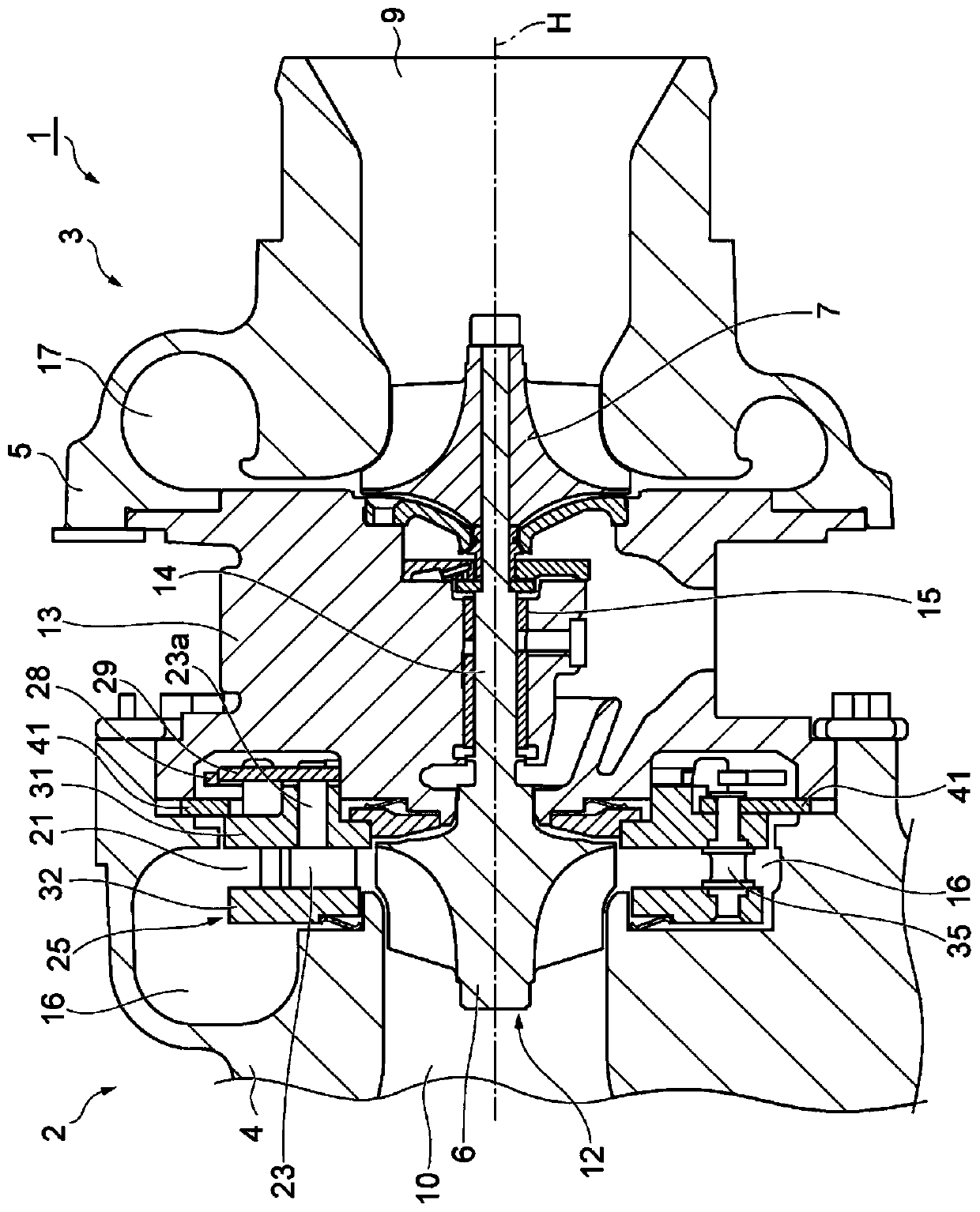

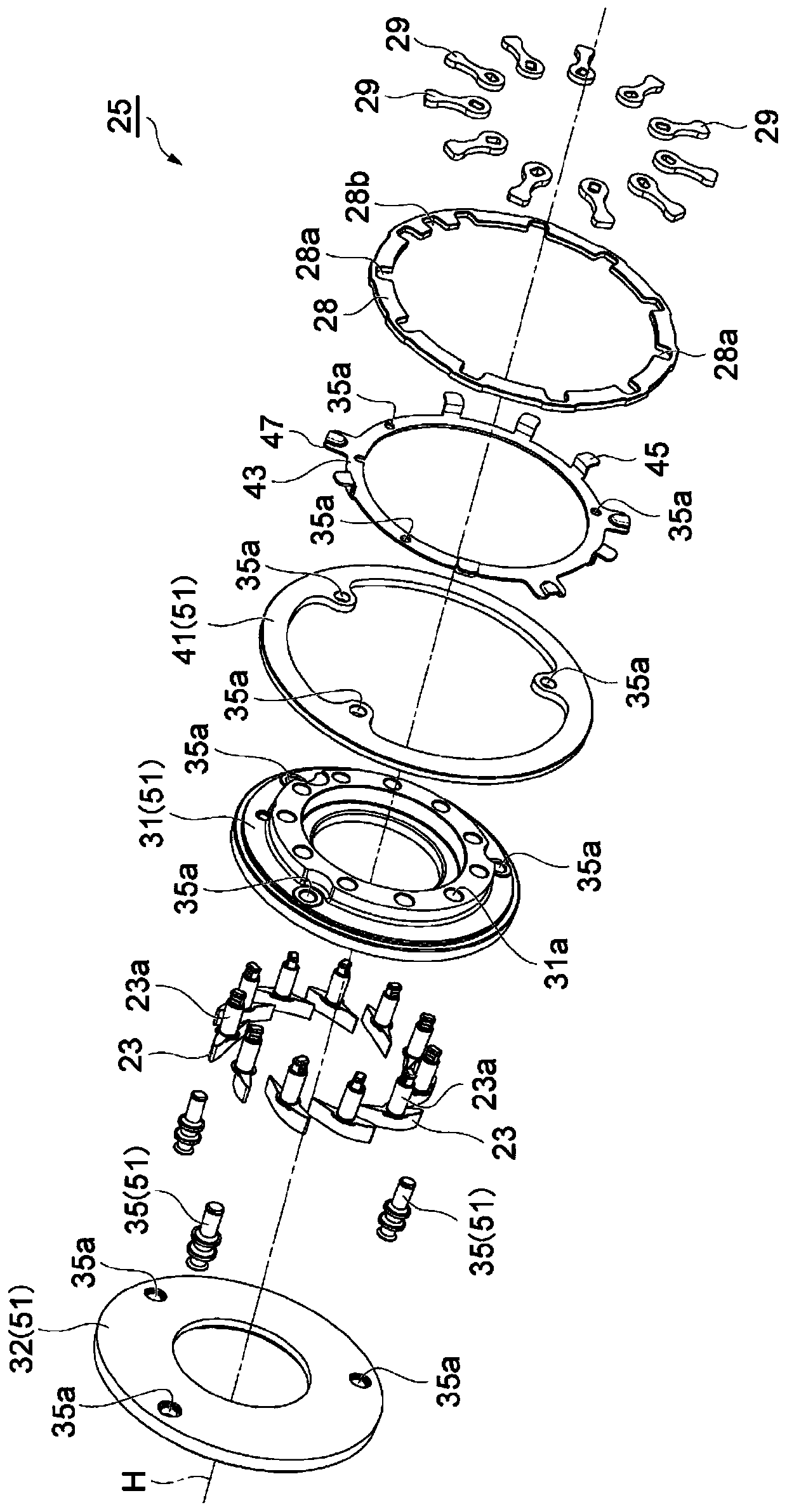

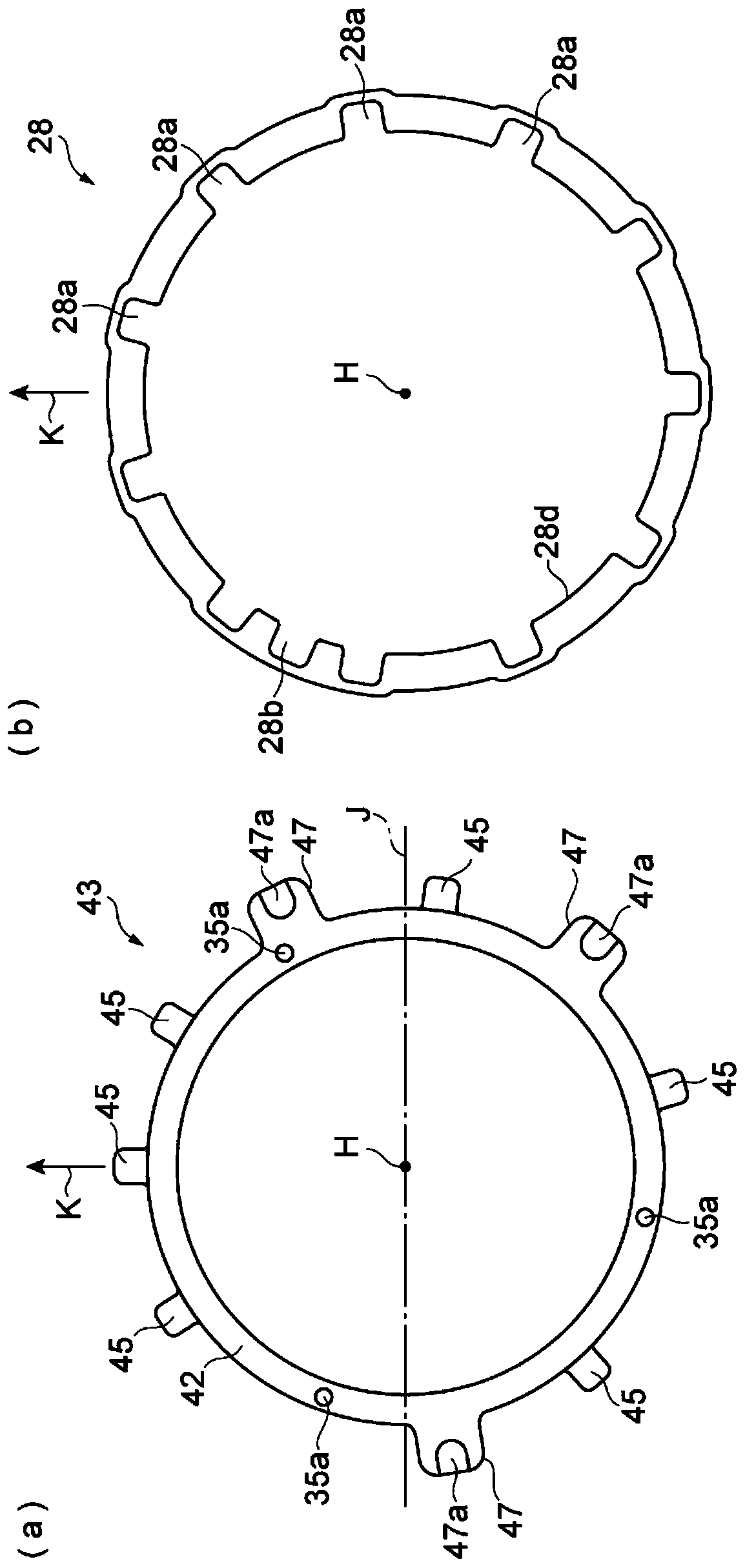

[0013] A variable capacity supercharger turbine according to one aspect of the present invention includes a turbine and a compressor, and the turbine has: a turbine wheel; a turbine housing forming a scroll flow path arranged around the turbine wheel; The variable nozzle unit includes a plurality of movable nozzle vanes arranged around the turbine impeller in the gas inflow path from the scroll flow path to the turbine impeller, and the compressor has a compressor impeller. The impeller is connected to the turbine impeller via a rotation shaft and rotates around the same rotation axis as the turbine impeller. The variable nozzle unit has a unit main body that is fixed to the turbine housing and supports a plurality of nozzle vanes as shafts. rotatable; a drive ring that rotates around a rotation axis relative to the unit main body and transmits driving force to a plurality of nozzle vanes; and a ring support member that is fixed to the unit main body and supports the drive ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com