Substrate destaticizing mechanism and vacuum treatment apparatus using same

A technology for vacuum processing device and substrate, which is applied in vacuum evaporation plating, ion implantation plating, gaseous chemical plating and other directions, can solve the problem of increasing the consumption of discharge electrodes and power consumption, and the partial elimination of electricity that cannot be charged with large amount of electricity. The effect of film formation area influence, etc., to achieve the effect of high efficiency, simplification, and optimization of electricity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

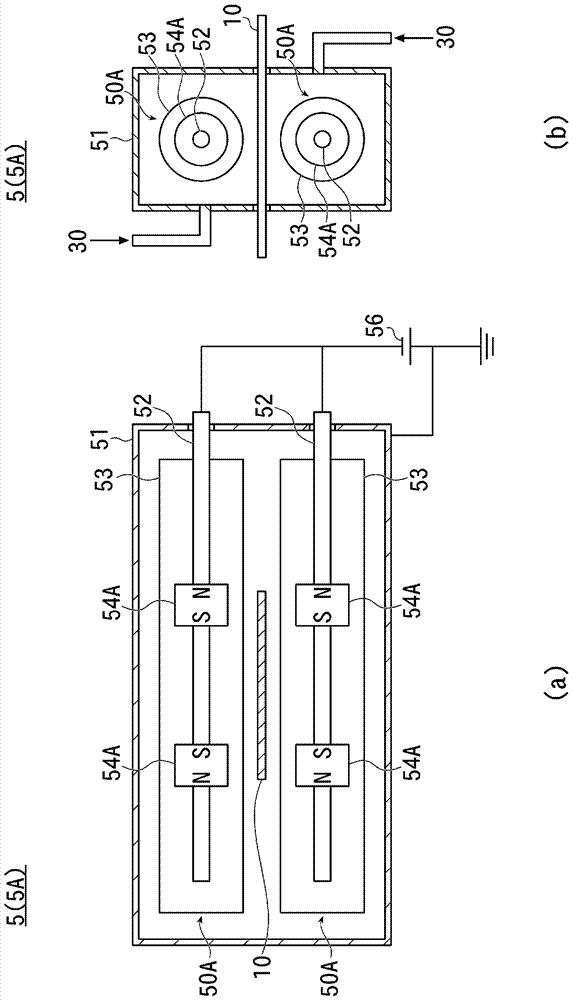

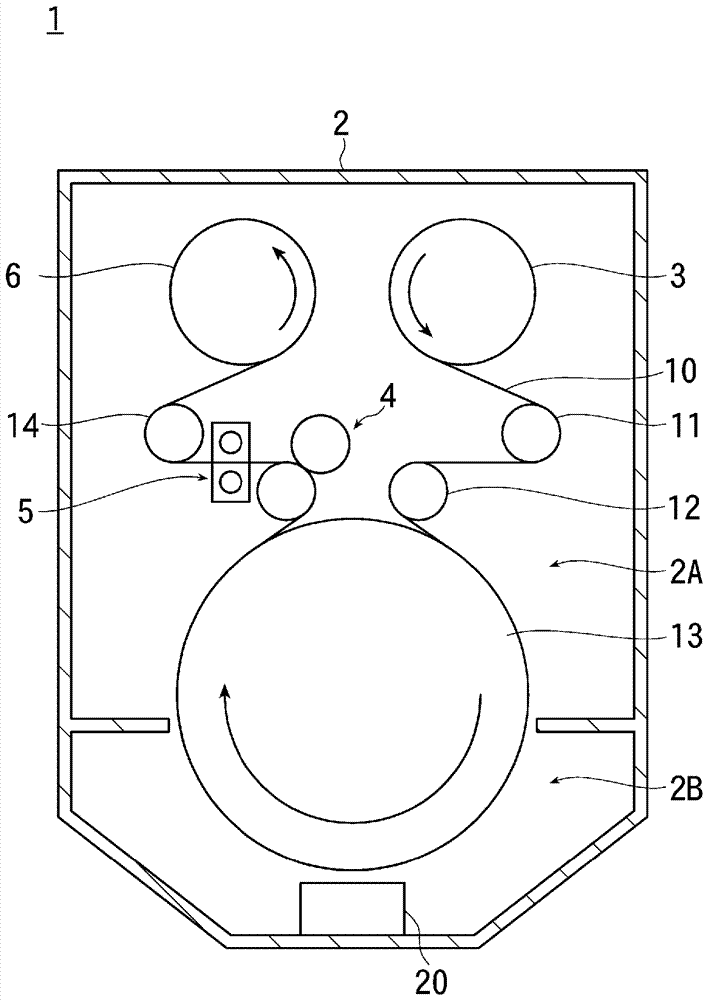

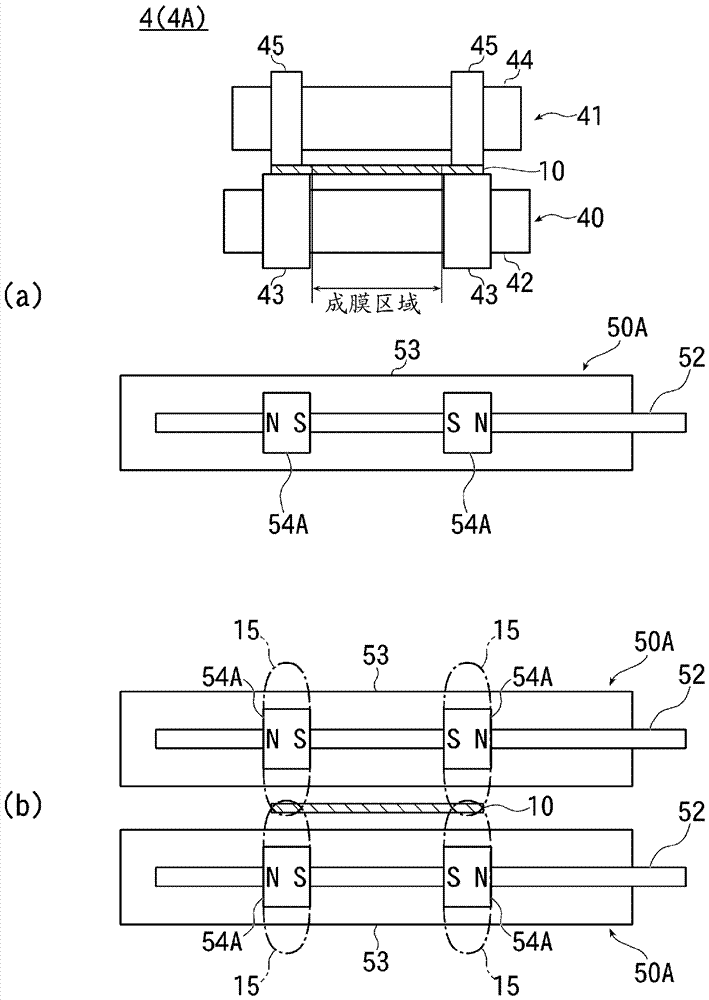

[0036] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0037] figure 1 It is a schematic configuration diagram showing an example of a roll-to-roll film forming apparatus as an embodiment of the present invention.

[0038] Below, take figure 1 The situation shown is taken as an example to illustrate the up-down relationship between components.

[0039] Such as figure 1 As shown, the roll-to-roll film forming apparatus (vacuum processing apparatus) 1 of the present embodiment includes a vacuum chamber 2 , has a feed / wind-up chamber 2A provided in the upper part of the vacuum chamber 2 , and a vacuum chamber 2A provided in the vacuum chamber 2 . The lower film forming chamber 2B.

[0040] The sending / winding chamber 2A and the film forming chamber 2B are respectively connected to an unillustrated vacuum exhaust system.

[0041] For example, in the upper part of the feeding / winding chamber 2A, there are provided a film-fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com