Cylindrical part fixing method suitable for measurement of Shaw hardness tester

A technology of Shore hardness and fixing method, applied in the field of fixing devices, can solve problems such as vibration and test result error, and achieve the effects of good reliability, reduced measurement error and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

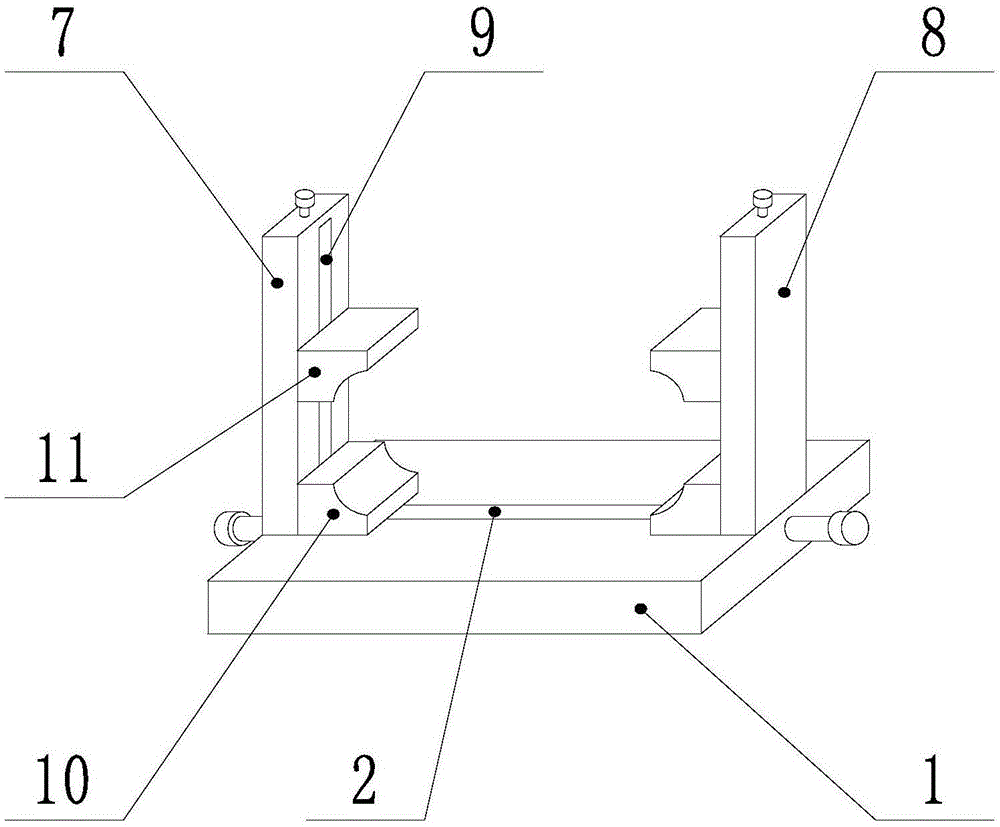

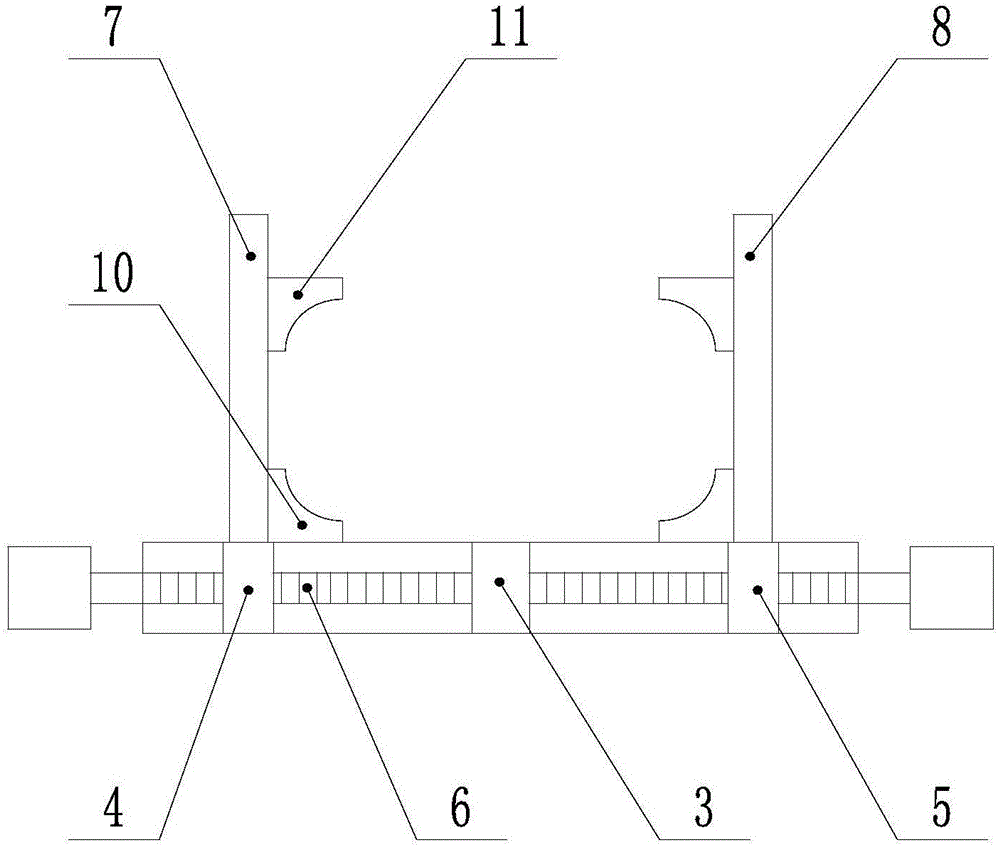

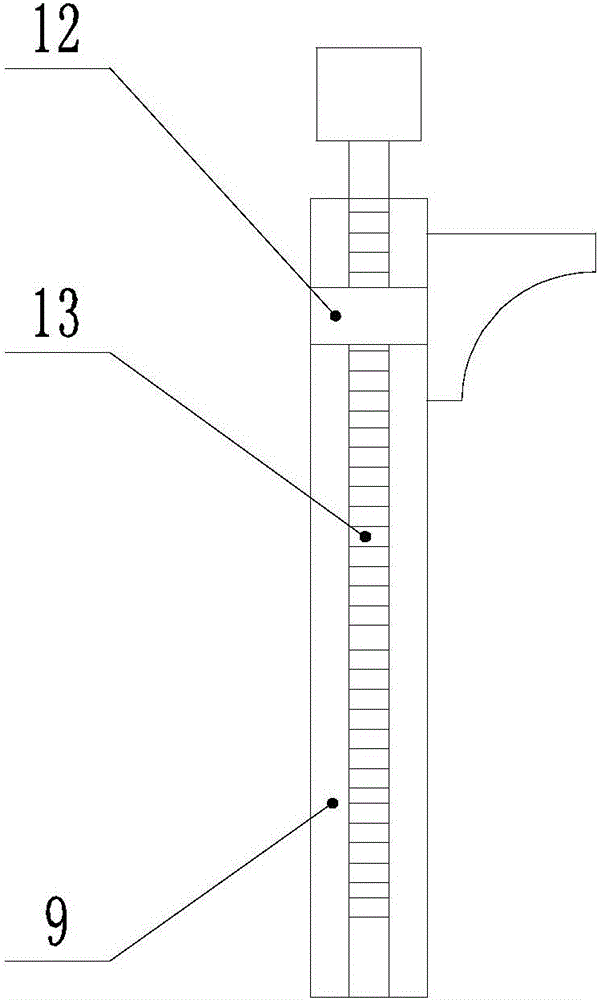

[0029] Such as Figure 1 ~ Figure 3 As shown, the fixing method for cylindrical parts suitable for Shore hardness tester includes the following steps:

[0030] S1: Place the base 1 on the stand of the Shore hardness tester, the base 1 is provided with a guide groove 2, and a stopper 3 is installed in the guide groove 2;

[0031] S2: Place the left sliding block 4 and the right sliding block 5 on both sides of the stopper 3 in the guide groove 2, the left sliding block 4 and the right sliding block 5 are provided with a screw-6, and one end of the screw-6 is connected to the stopper On the block 3, the other end is located outside the base 1, and the left sliding block 4 and the right sliding block 5 are all provided with threaded holes matched with the screw rod one 6, and the screw rod one 6 rotates with the left sliding block 4 and the right sliding block 5 respectively. together, and the left sliding block 4 and the right sliding block 5 can move along the guide groove 2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com