Method and device for detecting air leakage of beverage bottle

A detection device and detection method technology, which are applied in the direction of measurement device, fluid tightness test, machine/structural component test, etc. Other beverages and other issues, to achieve the effect of reliable data, accurate judgment methods, and simplified operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

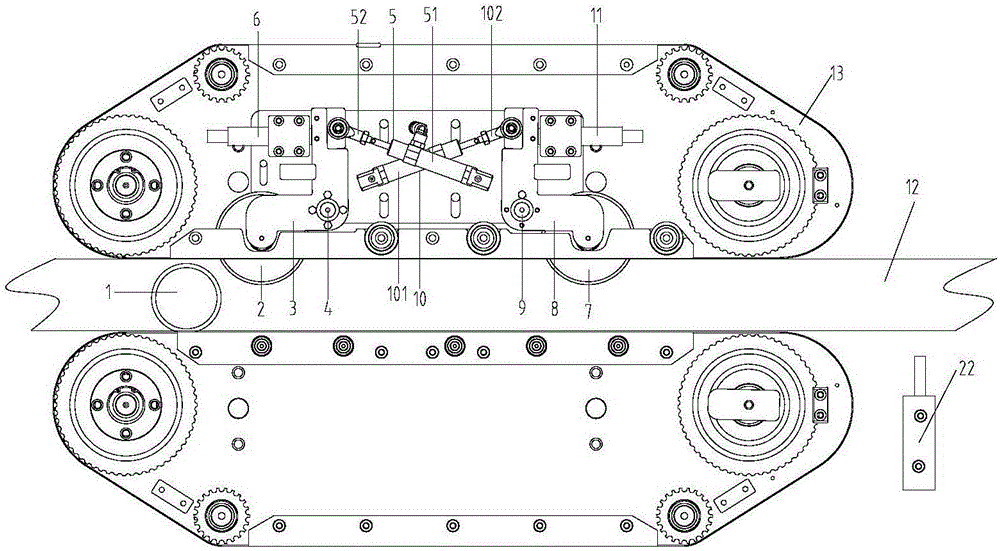

[0032] As the first embodiment of the beverage bottle air leakage detection method and device thereof according to the present invention, the method is realized by the beverage bottle air leakage detection device through the method, such as figure 1 As shown, the beverage bottle 1 is transported to the detection area through the transmission assembly. The transmission assembly includes a conveyor belt 12 and a belt pulley combination 13. The conveyor belt 12 and the belt pulley combination 13 together drive the beverage bottle 1 to move forward, which can realize the continuous movement of multiple beverage bottles. Detection, to achieve industrial assembly line production.

[0033] The first cam 2 and the second cam 7 in the detection area are telescopic. When the beverage bottle 1 enters the detection area, it first passes through the first cam 2, the beverage bottle 1 squeezes the first cam 2, and the first cam 2 shrinks inward due to the pressure, and the first cam 2 drive...

Embodiment 2

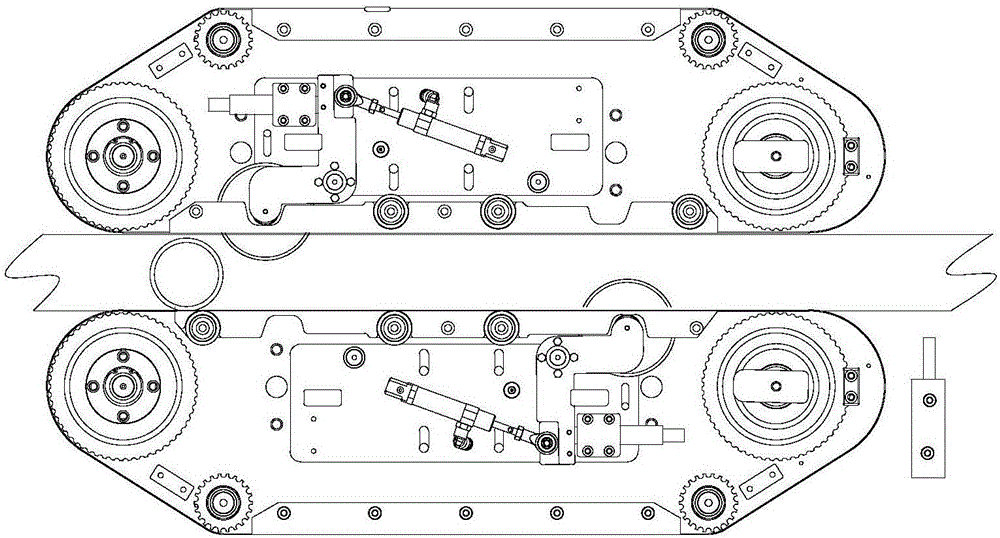

[0038] The difference between this embodiment and Embodiment 1 is that the double cam structure of Embodiment 1 is on the same side of the transmission assembly, and the double cams in this embodiment are distributed on both sides of the transmission assembly, such as figure 2 As shown, except that the structure is different from the first embodiment, the rest of the steps are consistent with the first embodiment.

Embodiment 3

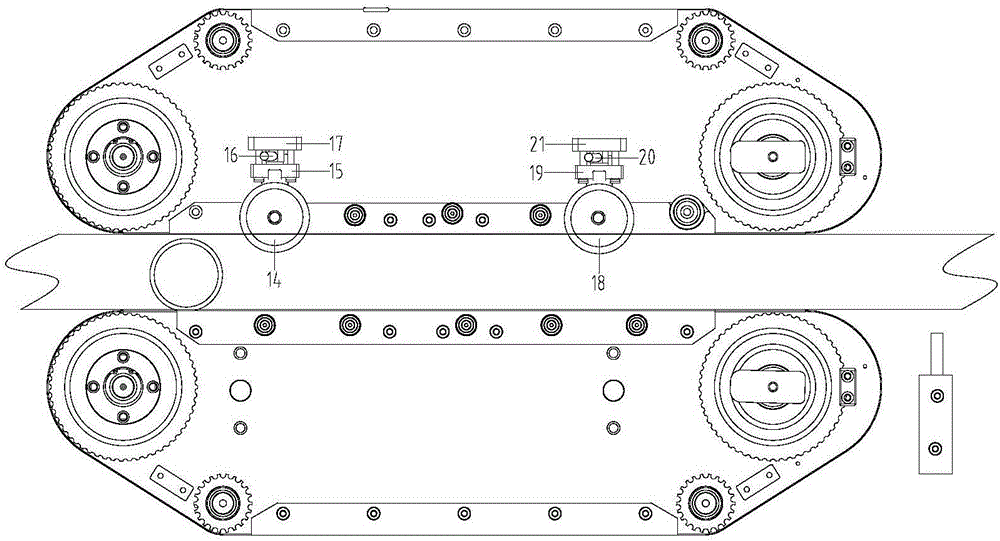

[0040] The difference between this embodiment and Embodiment 1 is that the pressure detection device is different, such as image 3 As shown, the pressure detection device in this embodiment uses the first pressure sensor 16 and the second pressure sensor 20 . The first pressure sensor 16 is in contact with the first cam 14 through the first bracket 15 , the first base 17 is used to fix the first pressure sensor 16 , and the second pressure sensor 20 is in contact with the second cam 18 through the second bracket 19 , the second base 21 is used to fix the second pressure sensor 20 . The beverage bottle first passes through the first cam 14, the first pressure sensor 16 transmits the measured data to the controller, then the beverage bottle passes through the second cam 18, and the second pressure sensor 20 also transmits the measured data to the controller , the controller judges whether there is air leakage in the beverage bottle by comparing the two sets of data.

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com