Support structure for floor casting

A supporting structure and floor slab technology, which is applied in building construction, on-site preparation of building components, construction, etc., can solve the problem that the force direction of the steel wire on the honeycomb core is not easy to control, the honeycomb core is prone to displacement, and the positioning accuracy of the honeycomb core is low and other issues to achieve the effect of high availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

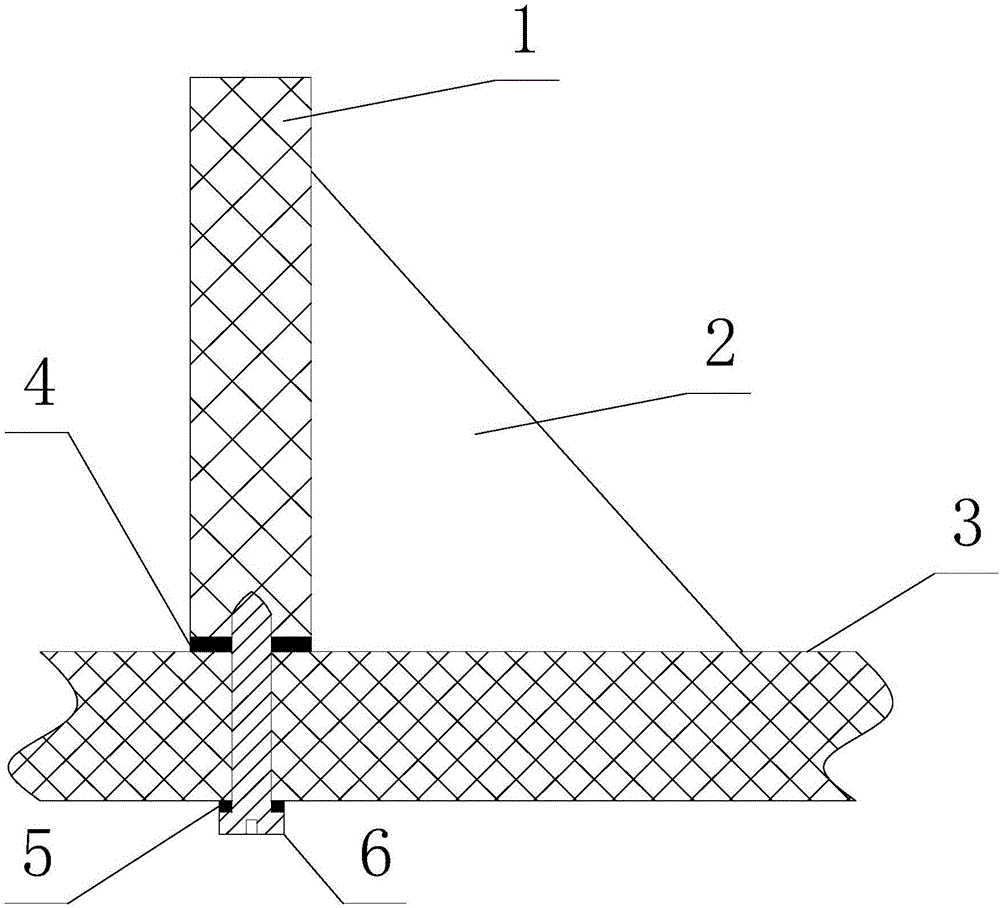

[0021] Such as figure 1 As shown, a support structure for floor slab pouring includes a bottom formwork 3, and also includes a side panel 1 and a connecting screw 6, and the side panel 1 is installed on the upper surface of the bottom formwork 3 through the connection screw 6, and the The connecting screw 6 passes through the bottom template 3 from the bottom surface of the bottom template 3 and is threadedly connected with the side panel 1 .

[0022] Specifically, this structure is used to pour the floor slabs with built-in honeycomb cores, that is, after the bottom formwork 3 and steel beams are erected, the honeycomb cores are placed on the bottom formwork 3, and the concrete is poured after the position constraints of the honeycomb cores are completed. A floor slab with a built-in honeycomb core is obtained.

[0023] In this solution, the upper side panel 1 is used to interact with the side of the honeycomb core to limit the position of the honeycomb core. In this way, it...

Embodiment 2

[0025] Such as figure 1 As shown, this embodiment is further limited on the basis of Embodiment 1: a first sealing strip 4 is sandwiched between the bottom template 3 and the side panel 1, and the side panel 1 forms a complete Rectangle. In the prior art, in order to avoid grout leakage in the gap between the honeycomb core and the bottom formwork 3, it is generally necessary to install a sealing ring between the honeycomb core and the bottom formwork 3, and the above sealing ring is used when adjusting the position of the honeycomb core and pouring concrete. There may also be a certain displacement relative to the honeycomb core. At the same time, since the sealing ring cannot be guaranteed to receive sufficient sealing specific pressure during subsequent concrete pouring, the actual sealing reliability of the above sealing rings is not high during use. In this solution, by setting the entire surface of the side of the honeycomb core or the bottom side of the side to fit the...

Embodiment 3

[0031] Such as figure 1 As shown, this embodiment further limits this case on the basis of the technical solution provided in Example 1, as the specific implementation of the bottom formwork 3 and the side panel 1, the bottom formwork 3 and the side panel 1 are both wooden boards . That is, the scheme can be well realized by adopting the widely used wooden formwork in the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com