A kind of method for preparing cefaclor by enzymatic method

A technology for preparing cefaclor and an enzymatic method, which is applied in the field of biomedicine, can solve the problems of unfavorable expansion of production and wide application of cefaclor, high solvent residue and insufficient purity, and achieves the advantages of good crystal shape, uniform crystal and shortened process route. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

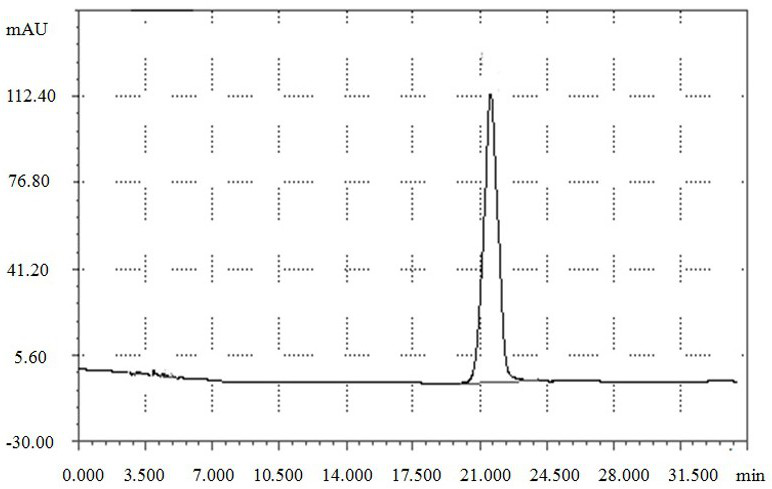

Image

Examples

Embodiment 1

[0027] A method for enzymatically preparing cefaclor, comprising the steps of:

[0028] (1) Dissolve 40g of 7-amino-3-chloro-cephem acid solid with ammonia water at 18°C to obtain a mother nucleus solution, add D-p-phenylglycine methyl ester hydrochloride solution to the mother nucleus solution to obtain a reaction solution, Among them, the D-p-phenylglycine methyl ester hydrochloride solution contains 41.3 g of D-p-phenylglycine methyl ester hydrochloride, adjust the pH to 6.5, cool down to 15 ° C, add 40 g of immobilized cefaclor synthase, and stir the reaction After 20 minutes, 0.1 g of cefaclor was added as a seed crystal, and after 30 minutes, D-p-phenylglycine methyl ester hydrochloride solution was continuously added dropwise for 2 hours at a rate of 1 mL / min. During the reaction, 7-amino-3-chloro - the residual amount of cephalosporin, and control the pH of the solution in the reaction process with 6mol / L hydrochloric acid and 3mol / L ammonia to be 6.5, and keep the r...

Embodiment 2

[0034] A method for enzymatically preparing cefaclor, comprising the steps of:

[0035] (1) Dissolve 40g of 7-amino-3-chloro-cephem acid solid with ammonia water at 18°C to obtain a mother nucleus solution, add D-p-phenylglycine methyl ester hydrochloride solution to the mother nucleus solution to obtain a reaction solution, Among them, the D-p-phenylglycine methyl ester hydrochloride solution contains 41.3 g of D-p-phenylglycine methyl ester hydrochloride, adjust the pH to 6.5, cool down to 15 ° C, add 40 g of immobilized cefaclor synthase, and stir the reaction After 20 minutes, 0.1 g of cefaclor was added as a seed crystal, and after 30 minutes, D-p-phenylglycine methyl ester hydrochloride solution was continuously added dropwise for 2 hours at a rate of 1 mL / min. During the reaction, 7-amino-3-chloro - the residual amount of cephalosporin, and control the pH of the solution in the reaction process with 6mol / L hydrochloric acid and 3mol / L ammonia to be 6.5, and keep the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com