Preparation method of porous graphene/polypyrrole electrode material

A technology of porous graphene and polypyrrole, applied in separation methods, chemical instruments and methods, water/sewage treatment, etc., can solve the problem of no obvious effect of graphene, and achieve improved conductivity, enriched pore structure, and increased specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

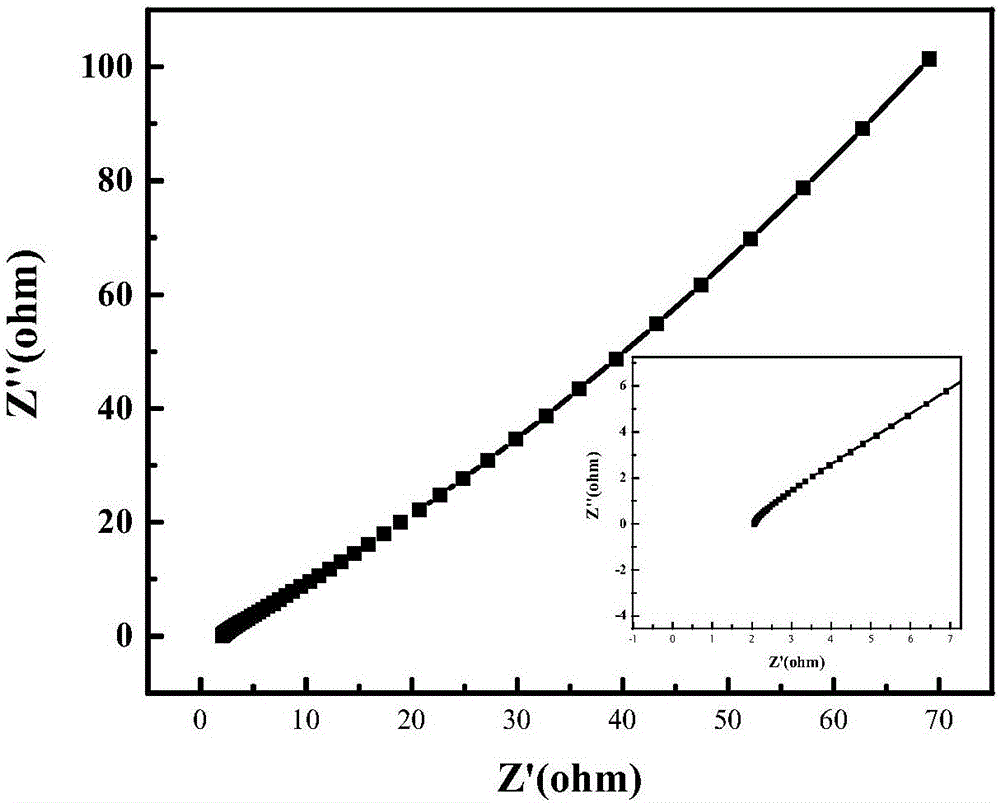

Image

Examples

Embodiment 1

[0026] (1) Prepare a 4mg / mL graphite oxide solution in a 250mL volumetric flask, and put it into an ultrasonic instrument for ultrasonic dispersion for 2 hours to obtain a graphene oxide solution.

[0027] (2) Add 1mL distilled water and 1mL ethanol to the beaker, then add 250uL pyrrole (pure pyrrole) and 60.4mL graphene oxide solution (that is, the mass ratio of graphene oxide to pyrrole is about 1:1) while stirring .

[0028] (3) Under the condition of vigorous stirring, add 9.8mg ferrous chloride tetrahydrate to the mixed solution in step (2). After mixing evenly, 722uL of hydrogen peroxide with a mass fraction of 30% (that is, the molar ratio of pyrrole to hydrogen peroxide is 1:2) was added dropwise to the mixed solution by a peristaltic pump at a speed of 500uL / min under the condition of an ice-water bath. ; The mass ratio of ferrous chloride tetrahydrate and hydrogen peroxide is 1:25). The reaction was continued for 24 h with constant stirring.

[0029] (4) Add 241.6...

Embodiment 2

[0032] (1) Prepare a 2mg / mL graphite oxide solution in a 250mL volumetric flask, and put it into an ultrasonic instrument for ultrasonic dispersion for 2 hours to obtain a graphene oxide solution.

[0033] (2) Add 1 mL of distilled water and 1 mL of ethanol to the beaker, and then add 250 uL of pyrrole (pure pyrrole) and 120.8 mL of graphene oxide solution (that is, the mass ratio of graphene oxide to pyrrole is 1:1) under stirring.

[0034] (3) Under the condition of vigorous stirring, add 2.45mg ferrous chloride tetrahydrate to the mixed solution in step (2). After mixing evenly, under the condition of an ice-water bath, 361uL of hydrogen peroxide with a mass fraction of 30% was added dropwise to the mixed solution by a peristaltic pump at a speed of 500uL / min (that is, the molar ratio of pyrrole to hydrogen peroxide was 1:1). ; The mass ratio of ferrous chloride tetrahydrate and hydrogen peroxide is 1:50). The reaction was continued for 24 h with constant stirring.

[003...

Embodiment 3

[0038] (1) Prepare 8mg / mL graphite oxide solution in a 250mL volumetric flask, and put it into an ultrasonic instrument for ultrasonic dispersion for 2 hours to obtain a graphene oxide solution.

[0039] (2) Add 1 mL of distilled water and 1 mL of ethanol to the beaker, and then add 250 uL of pyrrole (pure pyrrole) and 241.6 mL of graphene oxide solution (that is, the mass ratio of graphene oxide to pyrrole is 1:8) in a stirring state.

[0040] (3) Under the condition of vigorous stirring, add 9.8mg ferrous chloride tetrahydrate to the mixed solution in step (2). After mixing evenly, under the condition of an ice-water bath, 1444uL of hydrogen peroxide with a mass fraction of 30% was added dropwise to the mixed solution by a peristaltic pump at a speed of 500uL / min (that is, the molar ratio of pyrrole to hydrogen peroxide was 1:4). ; The mass ratio of ferrous chloride tetrahydrate and hydrogen peroxide is 1:50). The reaction was continued for 24 h with constant stirring.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com