Traction device with elastic stopping block function for rail vehicle

A technology for traction devices and rail vehicles, which is applied in the direction of traction devices, transportation and packaging, railway car body parts, etc. It can solve the problems of sacrificing the vertical comfort of rail vehicles, the limitation of the space under rail vehicles, and the difficulty of inspection and maintenance, and achieve daily Check the effect of ease of maintenance, reduction of manufacturing costs, and resolution of traction and snaking motion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

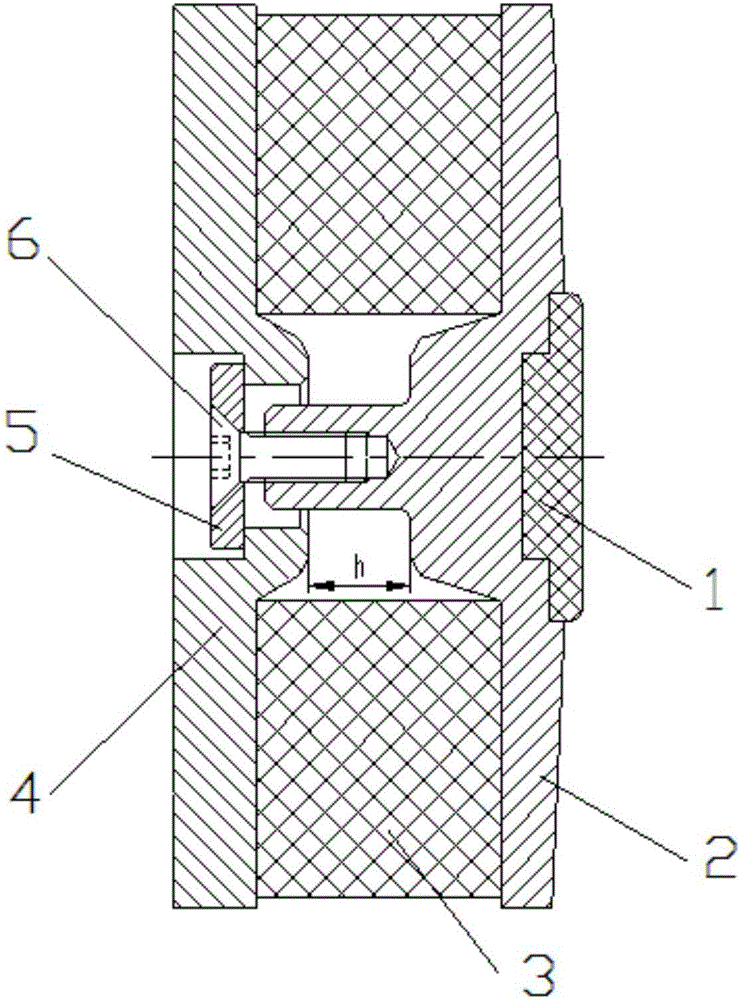

[0017] like figure 1 As shown, the rail vehicle traction device with elastic stop function in this embodiment has a vertically arranged pressure plate 2 and a back plate 4, an elastic element 3 is arranged between the pressure plate 2 and the back plate 4, and the back plate 4 is used to be fixed on the On the side of the bogie facing the corbel, the outer side of the pressure plate 2 is provided with a friction plate 1 for resisting the corbel of the rail vehicle from the longitudinal direction. The center of the pressure plate 2 protrudes toward the back plate, and the protrusion is provided with a screw hole. The center of the back plate is opened and a backing plate 5 is provided inside. The compression of the elastic element is realized by screwing the hexagon socket compression bolt 6 into the screw hole.

[0018] The friction plate 1 is made of synthetic materials such as nylon and aramid reinforced composite materials with good wear resistance. The pressing plate 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com