Car seat armrest mechanism capable of freely shifting gears

A technology for car seats and armrests, applied in the field of auto parts, can solve the problems that support gears cannot be switched at will, affect the safety effect of car seats, and are prone to safety problems, so as to achieve high work stability and reliability, improve The effect of easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

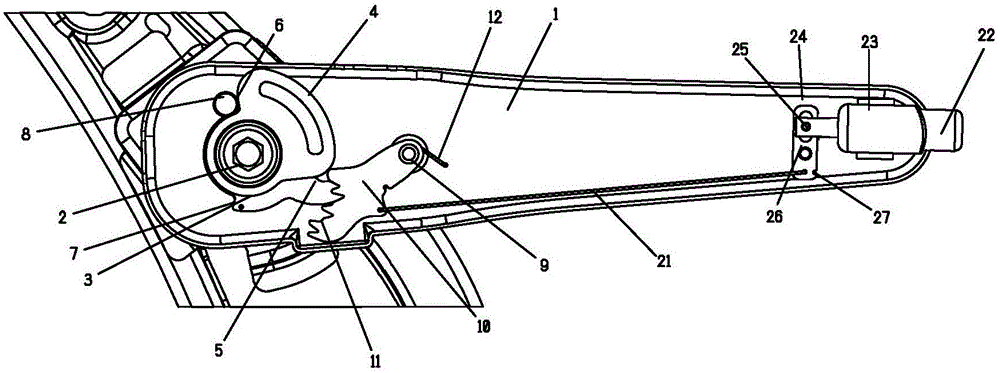

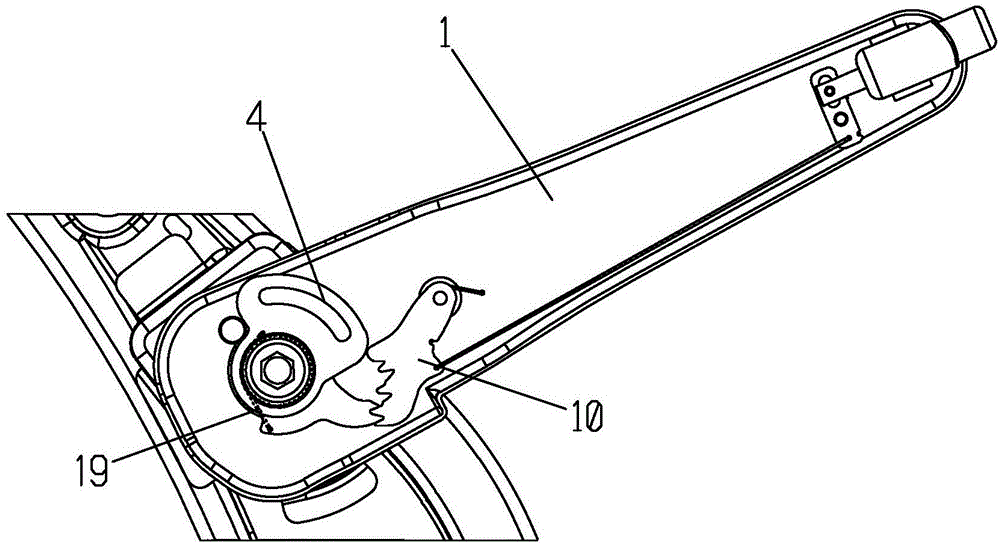

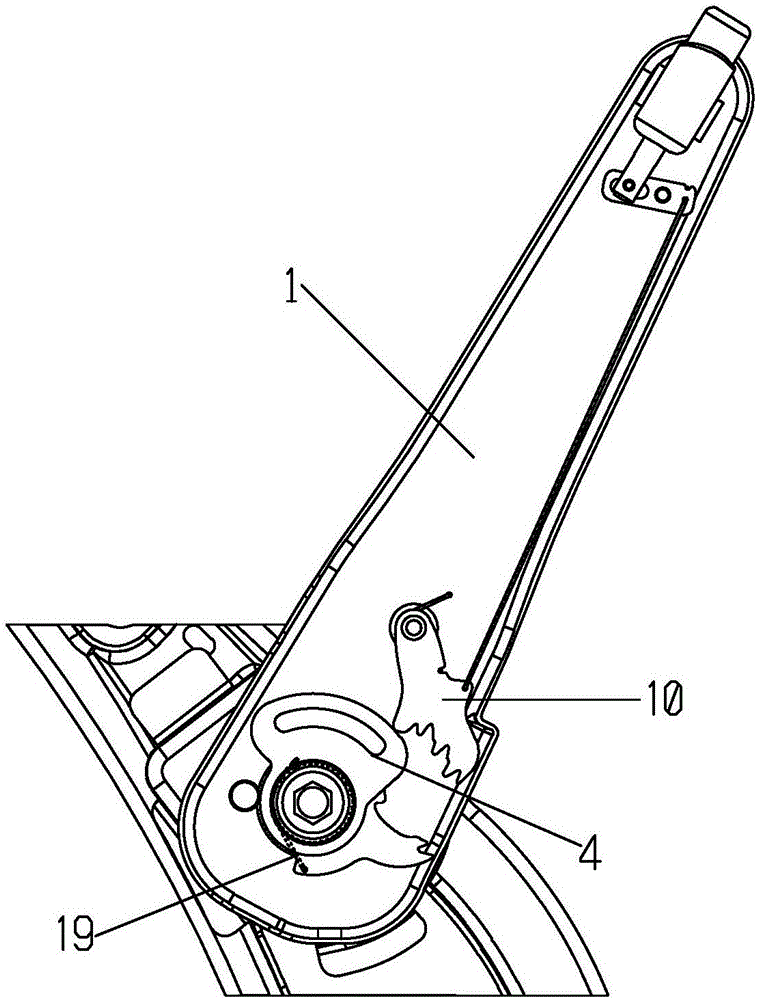

[0037] Such as Figure 1-Figure 7 As shown, the free-shifting car seat armrest mechanism of the present invention includes an armrest mounting plate 1, a locking piece 4, a limit pin 8, a hinge shaft 9, a hinge sleeve mounting bracket 17, an inner fixing plate 20 and an unlocking device;

[0038] A hinge sleeve 16 is fixedly installed on the hinge sleeve mounting bracket 17; the armrest mounting plate 1 is sleeved on the hinge sleeve 16, the armrest mounting plate 1 can rotate around the hinge sleeve 16; the hinge sleeve 16 is fixed with a fixed pawl 3. A limit torsion spring 19 is fitted on the hinge sleeve 16, one end of the limit torsion spring 19 is fixed on the fixed pawl 3, and the other end is on the flange of the rotating hole of the armrest mounting plate 1, in a free state.

[0039] A spring washer 13, a metal washer 14, a plastic washer 15 and a connecting bolt 2 are provided on the hinge sleeve mounting bracket 17.

[0040] The fixed pawl 3 has a limit stop and a fixed pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com