Roller monitoring device for rotating mill barrels

A monitoring device and rolling technology, applied in grain processing and other directions, can solve the problems of insignificant changes in resistance torque, increased resistance, and easy wear of blade-type probes, to meet flexibility and diversity, improve accuracy, Avoid annihilation and distortion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

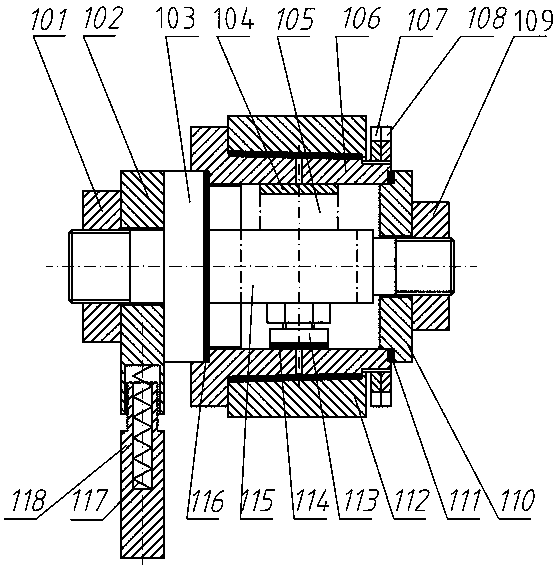

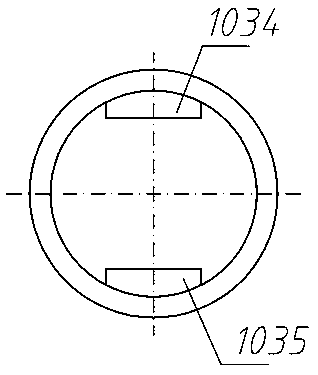

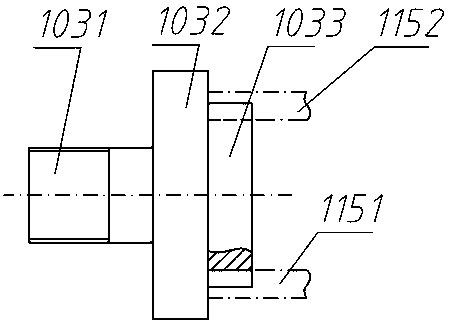

[0032] Example: see figure 1 —— Image 6 .

[0033] The invention discloses a rolling monitoring device suitable for a rotary mill cylinder, which includes a sensor 105, a cylindrical stator 106 is fixed outside the sensor 105, and an arc is arranged between the front end of the sensor 105 and the inner wall of the stator 106. Shaped block 104, the stator 106 is provided with a rotor 112 rotating around it, the outside of the rotor 112 is a cylindrical surface and the cylindrical surface is in rolling contact with the mill cylinder 2, and the linear speed of the two is the same.

[0034] The use principle of the present invention refers to Image 6 :

[0035]The present invention is applicable to a grinding machine state monitoring system, and is an online measurement system for monitoring the working state of the grinding machine and predicting the grinding characteristics by directly acquiring the vibration signal of the grinding machine cylinder. Its motion parameters a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com