Automatic through hole cleaning equipment for spinneret components

A technology for spinneret components and cleaning equipment, which is applied to spinneret assemblies, textiles, and papermaking. It can solve the problems of complicated cleaning process, high cleaning cost, and scrapped spinnerets, so as to achieve good cleaning effect and improve through-hole Work efficiency, improve continuous new effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

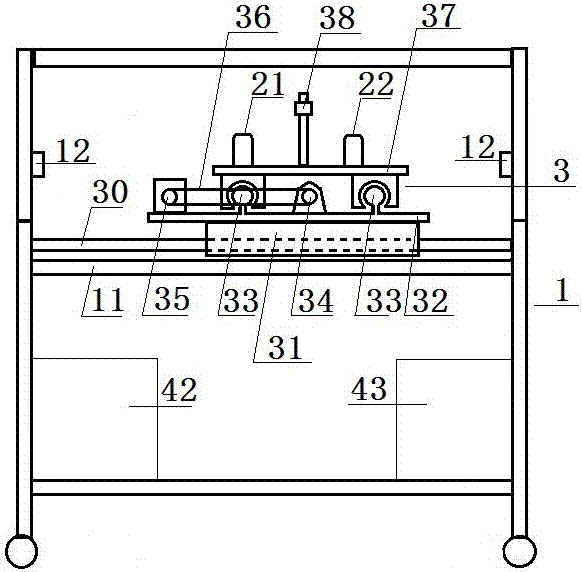

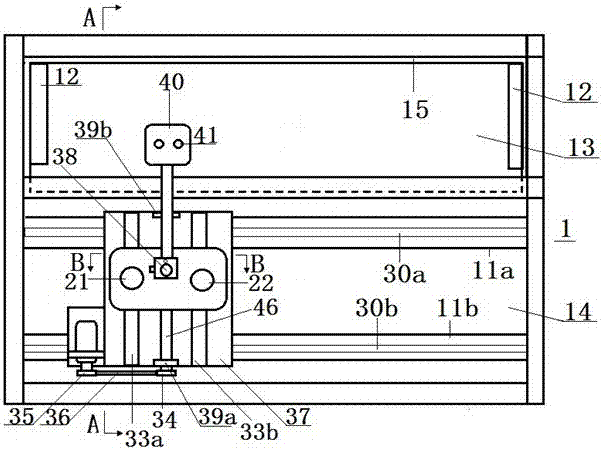

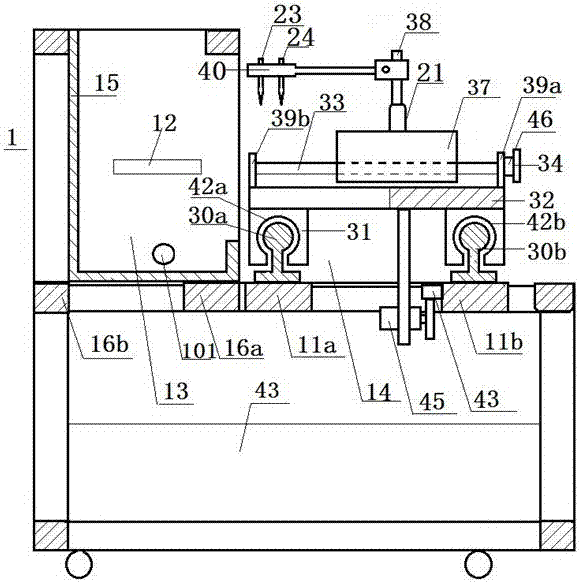

[0065] as attached figure 2 As shown, the automatic through-hole cleaning equipment for the spinneret assembly described in this embodiment includes a support 1, and a cleaning area 13 and a displacement control of adjacent cleaning areas are arranged on the support along the width direction of the support. District 14.

[0066] A high-pressure water body cleaning system is provided on the support 1, and a stage 12 for carrying the spinneret assembly is arranged in the cleaning area 13; the high-pressure water body cleaning system is above the spinneret assembly or / and A high-pressure water jet is generated below to remove attachments attached to the surface layer of the spinneret assembly or / and in the spinneret holes.

[0067] The high-pressure water jet produced by the high-pressure water cleaning system of this embodiment efficiently removes attachments attached to the surface layer of the spinneret assembly or / and inside the spinneret hole by adjusting the water pressur...

Embodiment 2

[0069] In this embodiment, on the basis of the high-pressure water body cleaning system in Embodiment 1, a displacement control mechanism and a control system are further provided. as attached figure 1 , figure 2 As shown, the displacement control mechanism 3 is arranged in the displacement control area 14 and is connected with the high-pressure water body cleaning system for driving the high-pressure water body jet along the transverse direction or / and longitudinal direction of the spinneret assembly For reciprocating motion. as attached Figure 5 As shown, the control system is composed of a touch screen 101 and a PLC 100 connected to the touch screen, and the PLC 100 is respectively connected to the displacement control mechanism 3 and the high-pressure water body cleaning system.

[0070] The displacement control mechanism and control system implemented in this implementation realize the automatic cleaning effect of the high-pressure water body cleaning system, which n...

Embodiment 3

[0072] This embodiment provides a further specific implementation manner for the displacement control mechanism of the second embodiment. as attached Figure 1 to Figure 3 As shown, the displacement control mechanism 3 includes: a longitudinal motion control mechanism 32, a lateral motion control mechanism 37 and a cleaning support platform, wherein: the longitudinal movement control mechanism 32 is used to drive the cleaning support platform to move along the longitudinal direction of the spinneret assembly. For reciprocating motion, a lateral motion control mechanism 37 is provided above the longitudinal motion control mechanism 32 for driving the cleaning support platform to reciprocate along the lateral direction of the spinneret assembly. The cleaning support platform is set above the lateral motion control mechanism 37, the cleaning support platform includes a leg end 38, a support platform end 40, and the leg end 38 is vertically fixedly connected to the end face of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com