Vibrating ore drawing machine in footrill

A technology of mine drawer and vibrating motor, which is applied in the directions of vibrating conveyor, conveyor, transportation and packaging, can solve the problems of slag leakage and slag loss, time-consuming and laborious, and kinetic energy consumption of vibrating mine drawer, so as to avoid slag leakage. and slag removal, energy saving and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

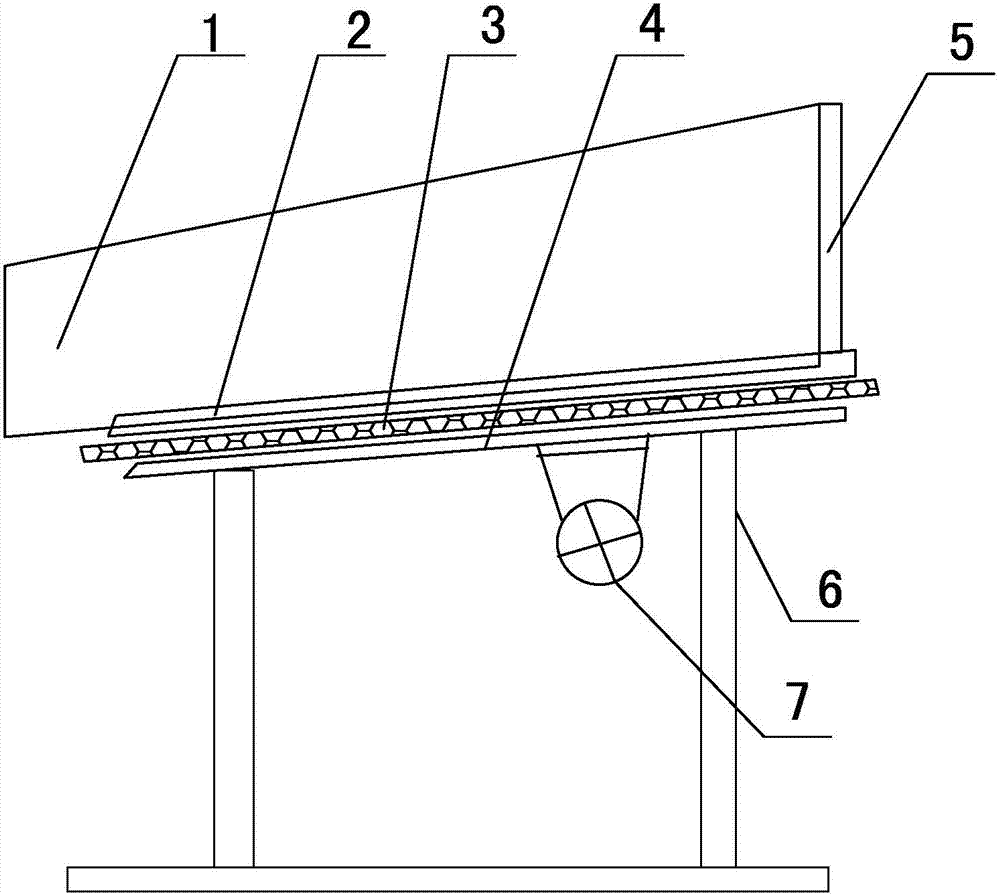

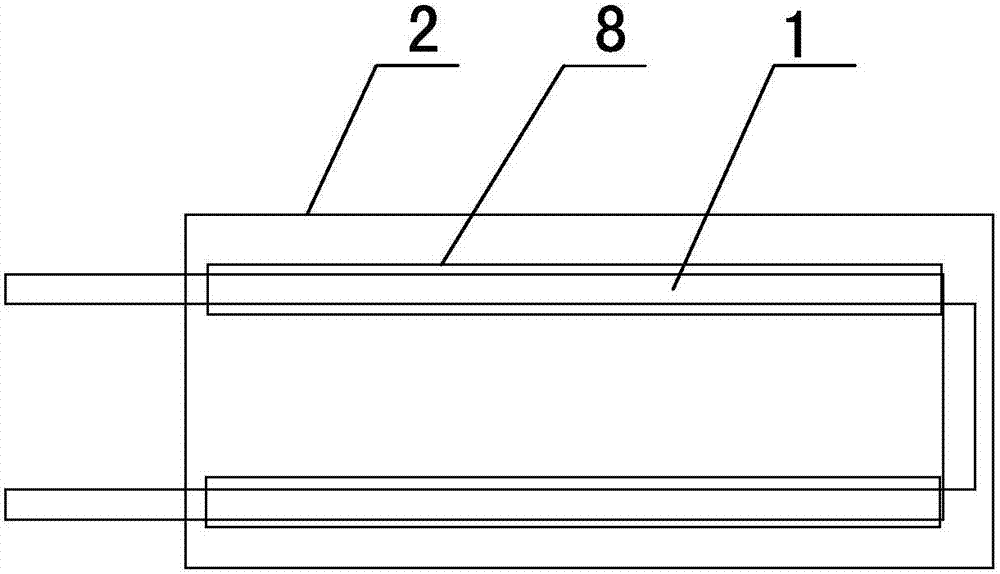

[0021] Such as figure 1 and figure 2 As shown, the vibrating ore-drawing machine in the adit includes a frame 6, a vibrating table 2 and a vibrating motor 7, and the top of the frame 6 is sequentially provided with elastic elements 4, crawlers 3 and a vibrating table 2; both sides of the vibrating table 2 A chute 8 is provided respectively, and a guard plate 1 is provided in the chute 8, and the chute 8 and the guard plate 1 are sealed by a sealing material; a horizontal plate 5 is provided at one end of the vibrating table 2, and the horizontal plate 5 is perpendicular to the chute 8; One end of the bottom of the elastic element 4 is provided with a vibrating motor 7 .

[0022] The number of the vibrating motors 7 is one group.

[0023] The sealing material is rubber.

[0024] Both ends of the guard plate 1 are respectively provided with reinforcing ribs, and damping springs are arranged between the reinforcing ribs and the frame 6 to reduce the force exerted by the guard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com