A layout method of an intelligent electric tractor and its chassis

A tractor, electric technology, applied in the direction of electric power unit, power unit, control device, etc., can solve the problems of difficult vehicle layout, uneven axle load distribution, and unsatisfactory axle load distribution of electric tractors, to ensure the passability and safety. Flexibility, reduce labor intensity, and facilitate the effect of chassis layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

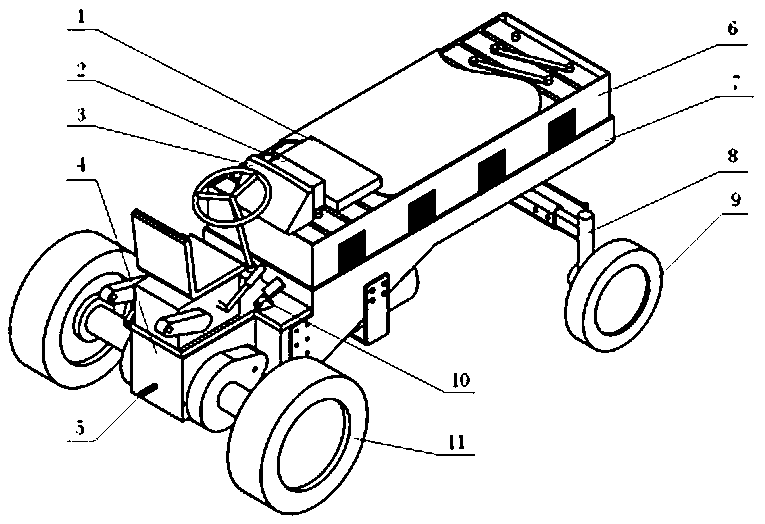

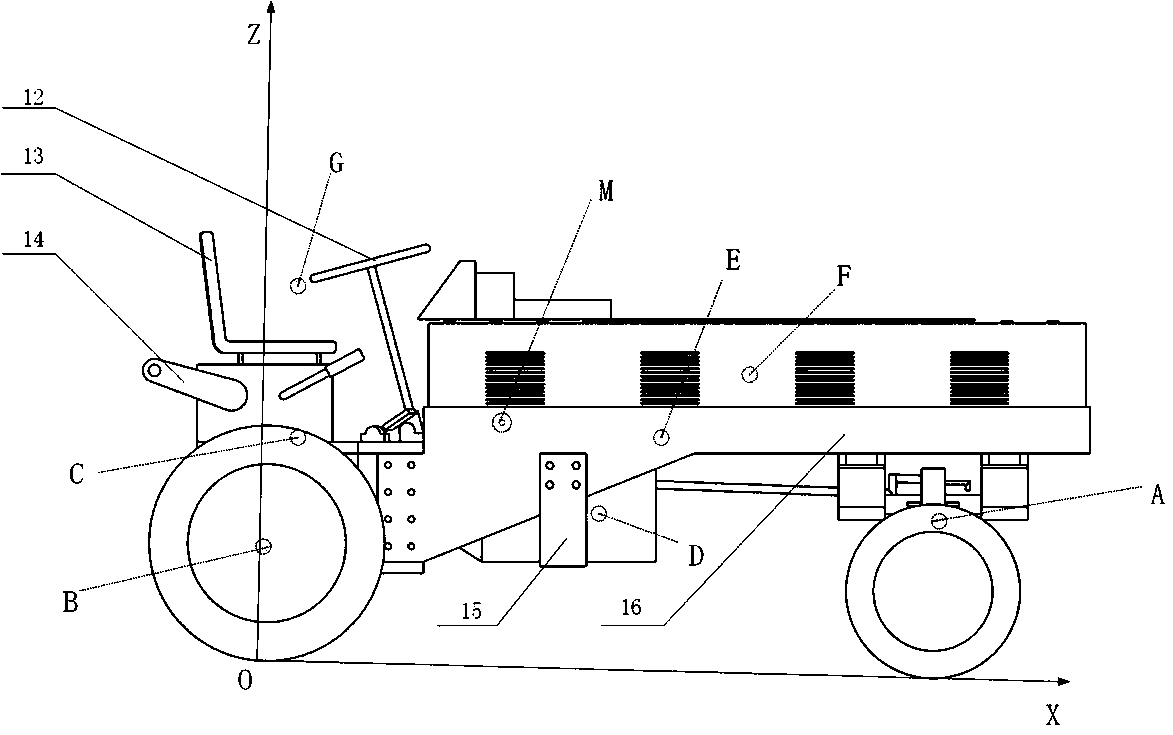

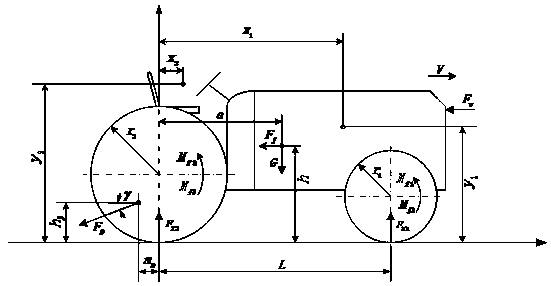

[0034] As shown in the figure, the specific implementation method is as follows:

[0035] An intelligent electric tractor, including a front frame 7 and a rear axle assembly 4, the front frame 7 is connected with the rear axle assembly 4 through several bolts to form a vehicle frame, and the bottom of the front frame 7 is far away from the rear axle Front axle 8 is installed on one end of assembly 4, and front wheel 9 is installed on the two ends of front axle 8, and trailing wheel 11 is installed on the rear axle assembly 4, is connected on the rear axle assembly 4 and is used for providing for the rear hanging working parts. The power output shaft 5 of the power, the front wheel 9 and the rear wheel 11 cooperate to support the vehicle frame, and the top of the front frame 7 is divided into a battery box installation part 16, and the battery box installation part 16 is fixed with a power battery box 6 by bolts , the bottom of the front frame 7 is divided into a motor installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com