hydraulic gearbox

A hydraulic gearbox and gear technology, applied in the field of gearboxes, can solve problems such as inconvenient operation, problems, unfavorable maintenance, etc., and achieve the effect of simple structure, simple increase of gears, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

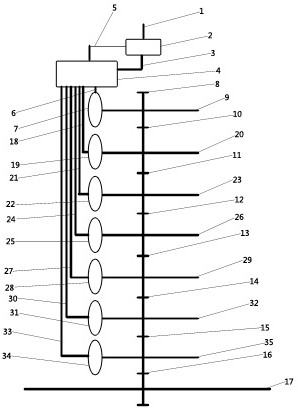

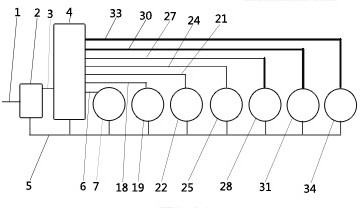

[0014]The specific embodiments of the present invention will be described in further detail by the description of the examples. Such asfigure 1 As shown, the liquid transmission, including the input shaft 1, the output shaft 17, the driven gear 16, the oil pump 2, the oil circuit controller 4, turbine, and gear gears, wherein the turbine includes a turbine 7, a reverse turbine 19, the two-stage turbine 22, the three-speed turbine 25, the four-speed turbine 28, the five-dimensional turbine 31 and the six-speed turbine 34, and they are arranged in parallel, the output shaft 17 and the first gear 8, and the reverse gear 10 is provided in parallel. The two gear 11, the three gear 12, the four gear 13, the five-speed gear 14, the six-speed gear 15, and the driven gear, wherein the first turbine 7 and the first gear 8 are connected together by a round axis 9. And fixed to the transmission housing, the reverse turbine 19 and the reverse gear 10 are connected together by the reverse wheel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com