Antistatic breathable fabric

An antistatic and antistatic layer technology, applied in the textile field, can solve the problems of softness and moisture absorption of fabrics, which cannot meet people's requirements for clothing fabrics, and reduce the comfort of wearing clothes, etc., and achieve high market application value , simple structure, good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

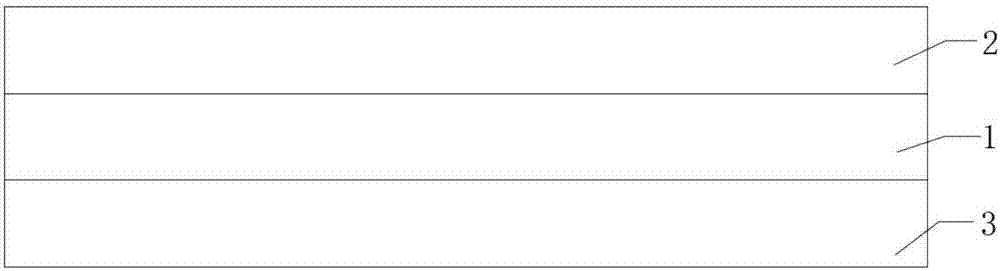

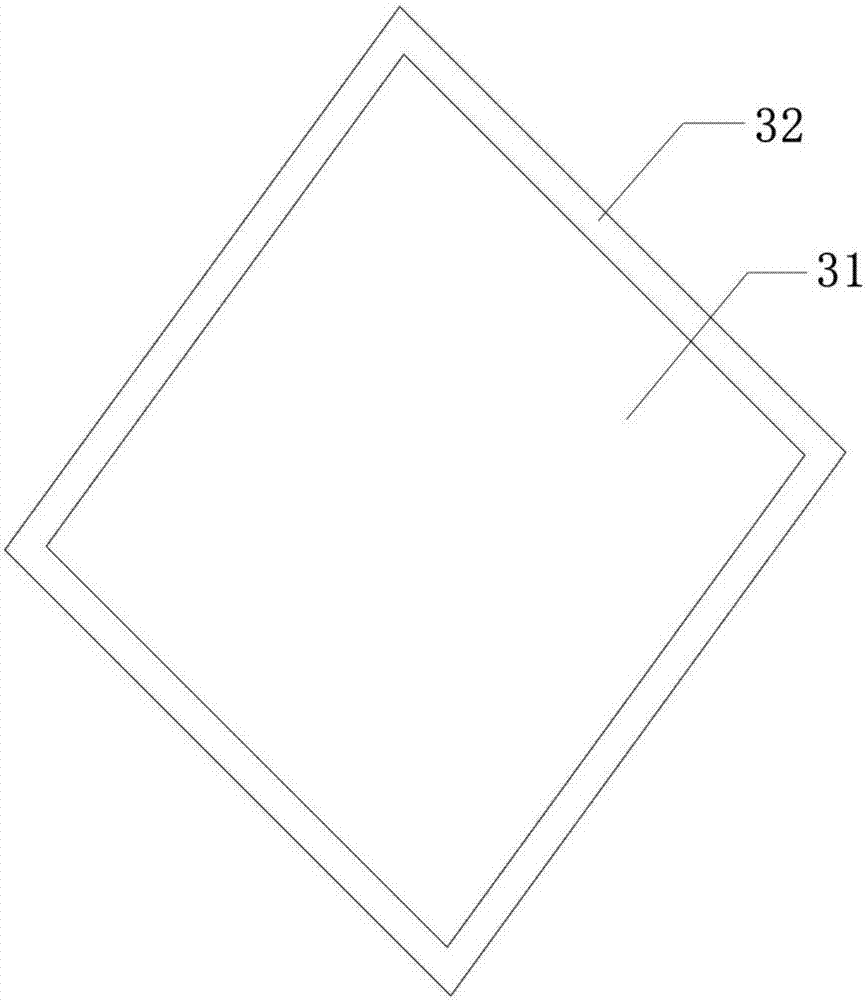

[0021] like figure 1 The antistatic breathable fabric shown is composed of a base layer 1, an antistatic layer 2 and a breathable layer 3, the upper layer of the base layer 1 is provided with an antistatic layer 2, the lower layer of the base layer 1 is provided with a breathable layer 3, and the base layer 1, the antistatic layer After the electrostatic layer 2 and the air-permeable layer 3 are bonded by adhesive polyurethane, they are integrally formed by heat pressing. Wherein, the base layer 1 includes the following components by weight components: 20 parts of rabbit hair, 10 parts of rabbit down, 3 parts of polyacrylonitrile fiber, 1 part of iron nitrate, 2 parts of polyester resin, 3 parts of ammonium persulfate and polyurethane 2 parts. In addition, if figure 2 As shown, the air-permeable layer 3 is a honeycomb structure, and the honeycomb structure is a three-dimensional quadrilateral, including honeycomb holes 31 and side walls 32 . And, the air-permeable layer 3 ...

Embodiment 2

[0023] like figure 1 The antistatic breathable fabric shown is composed of a base layer 1, an antistatic layer 2 and a breathable layer 3, the upper layer of the base layer 1 is provided with an antistatic layer 2, the lower layer of the base layer 1 is provided with a breathable layer 3, and the base layer 1, the antistatic layer After the electrostatic layer 2 and the air-permeable layer 3 are bonded by adhesive polyurethane, they are integrally formed by heat pressing. Wherein, the base layer 1 includes the following components by weight components: 50 parts of rabbit hair, 30 parts of rabbit down, 12 parts of polyacrylonitrile fiber, 5 parts of iron nitrate, 12 parts of polyester resin, 5 parts of ammonium persulfate and polyurethane 10 parts. In addition, if figure 2 As shown, the air-permeable layer 3 is a honeycomb structure, and the honeycomb structure is a three-dimensional quadrilateral, including honeycomb holes 31 and side walls 32 . And, the air-permeable laye...

Embodiment 3

[0025] like figure 1 The antistatic breathable fabric shown is composed of a base layer 1, an antistatic layer 2 and a breathable layer 3, the upper layer of the base layer 1 is provided with an antistatic layer 2, the lower layer of the base layer 1 is provided with a breathable layer 3, and the base layer 1, the antistatic layer After the electrostatic layer 2 and the air-permeable layer 3 are bonded by adhesive polyurethane, they are integrally formed by heat pressing. Wherein, the base layer 1 includes the following components by weight components: 40 parts of rabbit hair, 10 parts of rabbit down, 3 parts of polyacrylonitrile fiber, 1 part of iron nitrate, 8 parts of polyester resin, 5 parts of ammonium persulfate and polyurethane 2 parts. In addition, if figure 2 As shown, the air-permeable layer 3 is a honeycomb structure, and the honeycomb structure is a three-dimensional quadrilateral, including honeycomb holes 31 and side walls 32 . And, the air-permeable layer 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com