Wire dispensing production line

A production line and glue dispensing technology, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc., can solve the problems affecting the dispensing effect, the dispensing amount cannot be accurately controlled, rework dispensing and other problems, and achieve improvement The effect of dispensing efficiency, enhancing social competitiveness and improving dispensing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

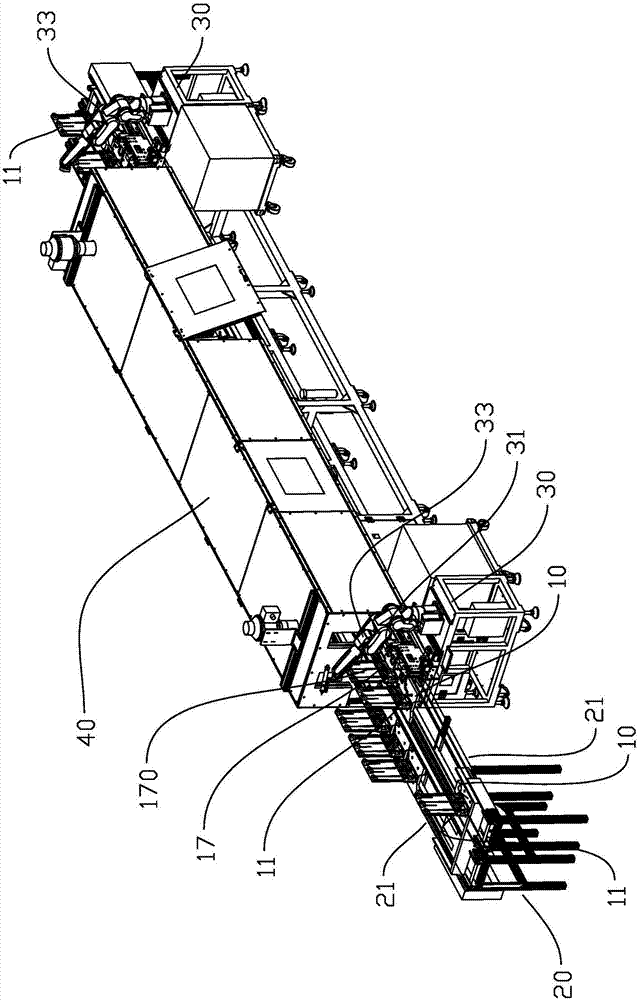

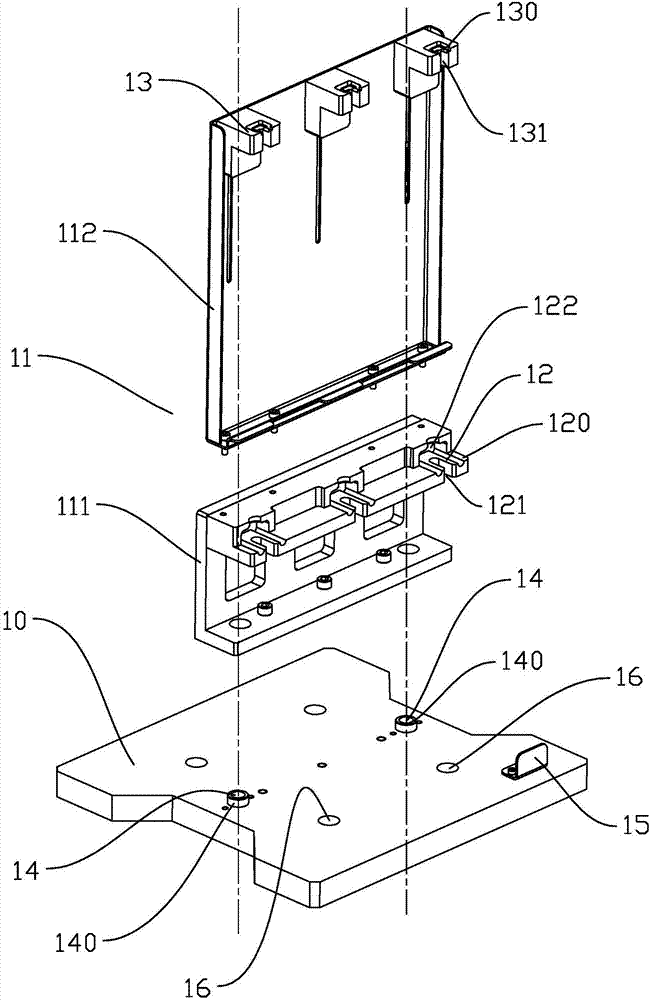

[0038] refer to figure 1 , a wire dispensing production line, including a conveying device, on which a tooling mechanism for loading workpieces to be glued is movably arranged, in the present invention, the workpiece is a sheath, and the sheath The sleeve is equipped with a wire harness; the conveying device is used to drive the tooling mechanism to move; one side of the conveying device is provided with more than one dispensing device, and the dispensing device is located at the position where the tooling mechanism moves, That is to say that the dispensing device is located in front of the advancing direction of the tooling mechanism, and the conveying device can drive the tooling mechanism to drive the workpieces to be dispensed to move together to the position of the dispensing device; One side of the glue device is also provided with a curing furnace, and the conveying device passes through the curing furnace; wherein, the conveying device transports the tooling mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com