Device for quantitatively mixing double chemical liquid reagents

A quantitative mixing and two-liquid technology, applied in the direction of mixers, mixing methods, chemical instruments and methods, etc., can solve the problems of only one-way stirring, layering, and poor stirring effects, so as to achieve full mixing and improve the effect , to avoid layered effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

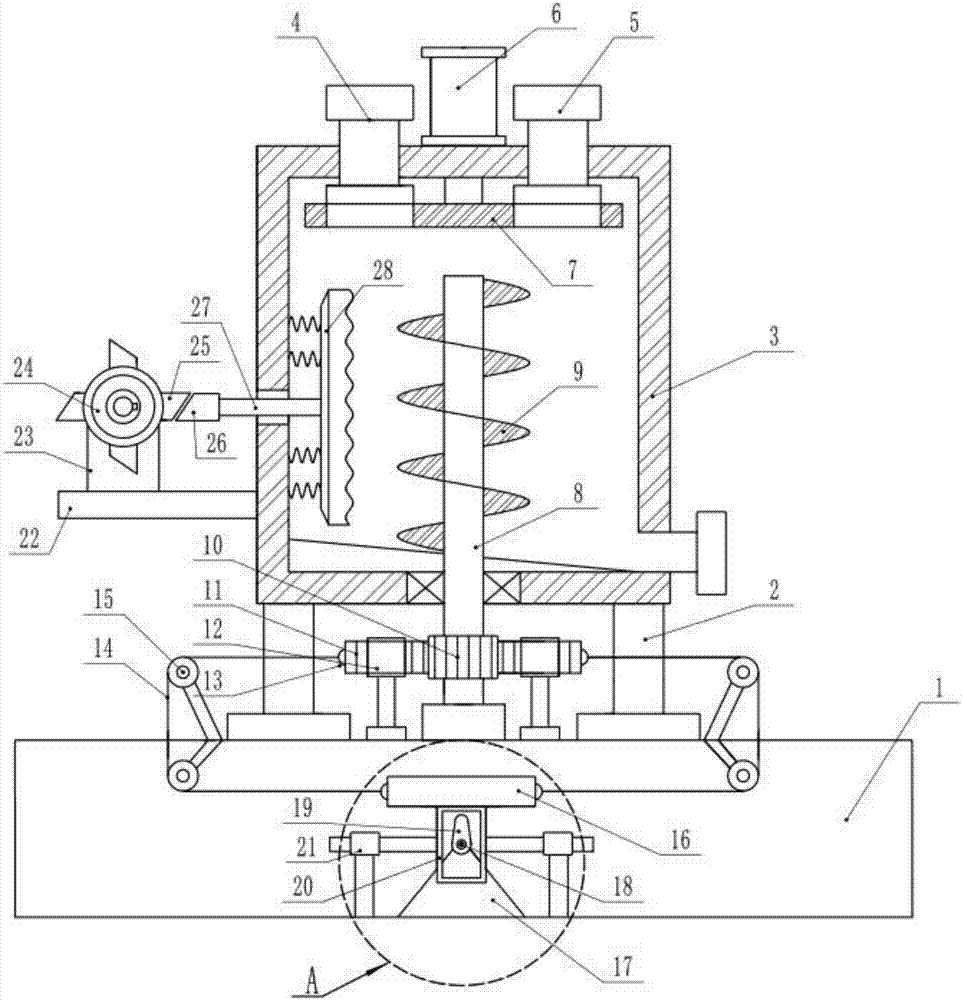

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

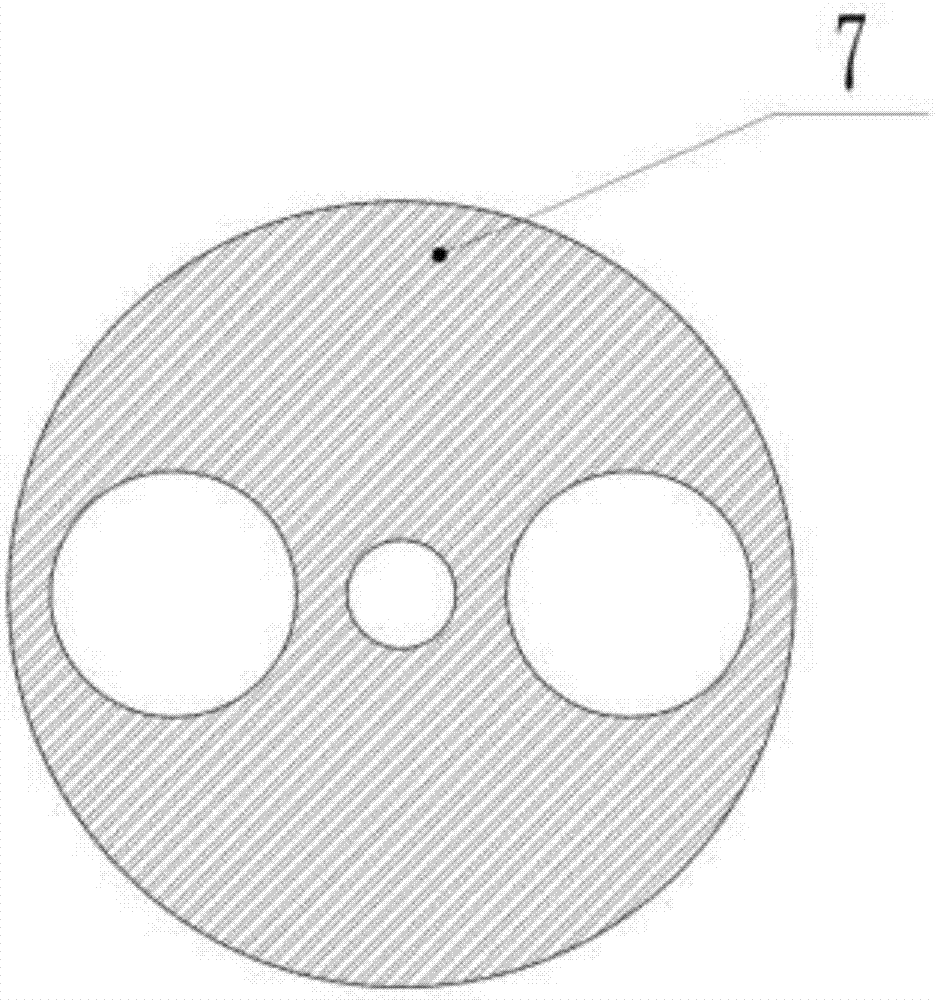

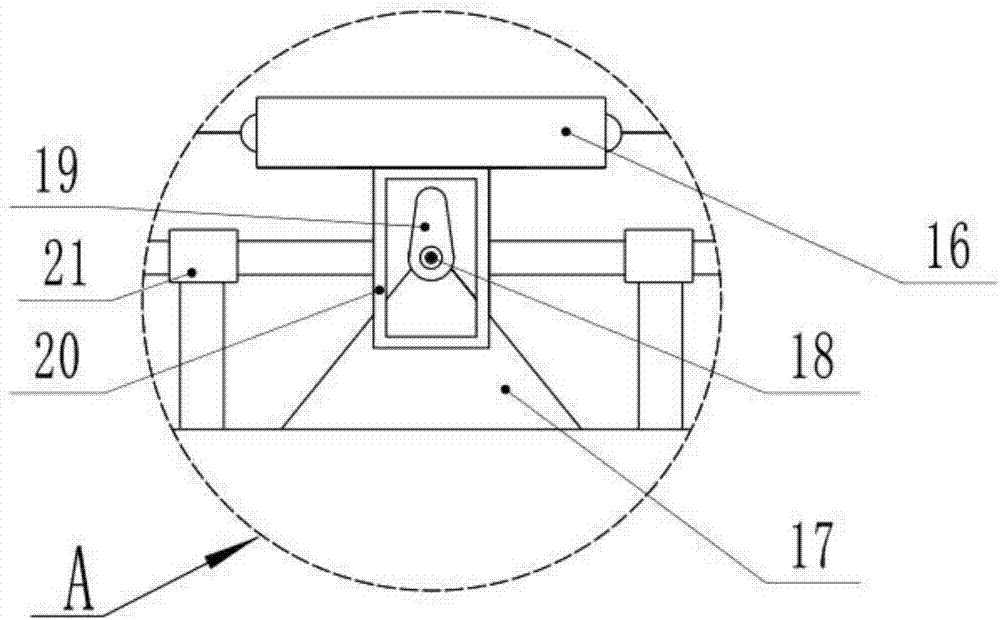

[0021] see Figure 1-3 , a quantitative mixing device for chemical two-liquid reagents, comprising a mixing box 3, a charging motor 6, a feeding turntable 7, a first driving motor 18, a cam 19, a second driving motor 23 and a corrugated spoiler 28, the base 1 A support column 2 is welded on the top, and a mixing box 3 is fixedly installed on the upper side of the support column 2. The upper side of the mixing box 3 is symmetrically inserted and installed with a first feed pipe 4 and a second feed pipe 5. The first feed pipe 4 The size and specification of the second feed pipe 5 are exactly the same and are made of corrosion-resistant hard plastic. The upper center of the mixing box 3 is also fixedly installed with a feeding motor 6. The output shaft of the feeding motor 6 is vertically downward and Protruding into the inside of the mixing box 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com