Novel full-automatic safety prewarning pollution-free environment-friendly semi-finished product degassing device

A technology of safety early warning and degassing device, which is applied in the direction of foam dispersion/prevention, can solve the problems of incomplete airtightness of degassing tank, environmental and human damage, injury and loss, etc., to achieve pollution-free discharge and reduce Effects of pollution and reduction of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

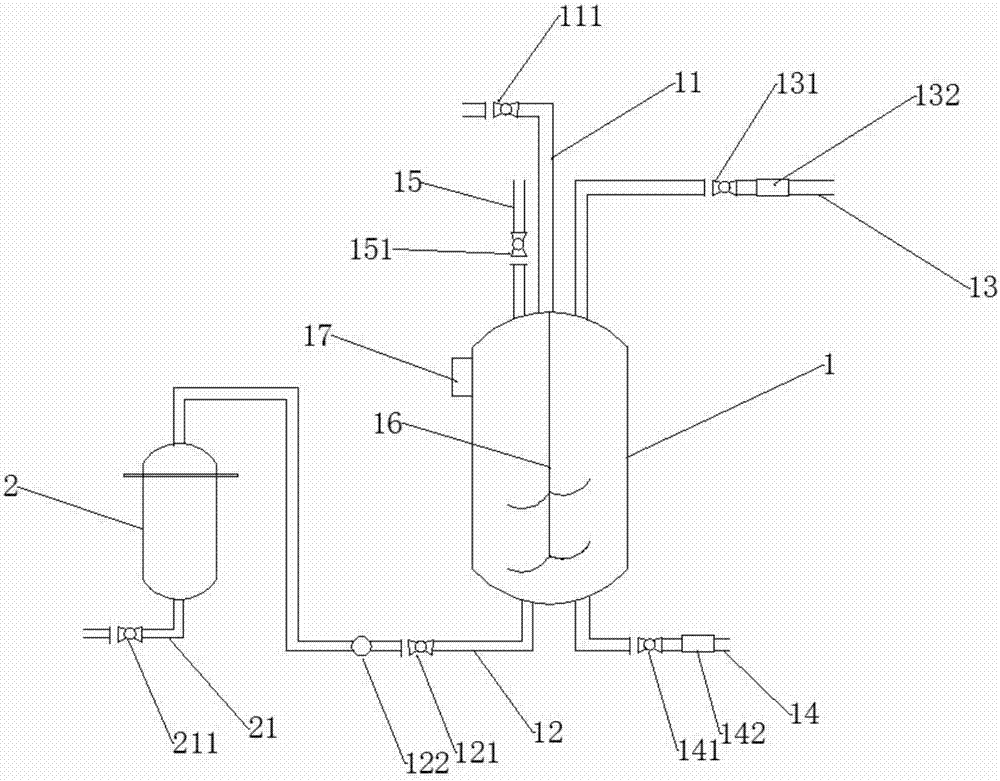

[0016] The technical solutions of the present invention will be further specifically described below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0017] Example combination figure 1 As shown, a new type of fully automatic safety early warning non-polluting environmental protection semi-finished product degassing device, in this embodiment, the new fully automatic safety early warning non-polluting environmental protection semi-finished product degassing device includes a degassing tank 1 part, material delivery part, gas delivery part, a constant pressure part, a stirring device part and a gas early warning device part, the material delivery part includes a feed pipe 11 positioned at the top of the degasser 1 and a discharge pipe 12 positioned at the bottom of the degasser 1, the feed pipe 11 is provided with a feed check valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com