Material quality assessment method based on machine learning

A quality assessment and machine learning technology, applied in the field of power systems, which can solve problems such as single linked data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A method for evaluating material quality based on machine learning, comprising the following steps:

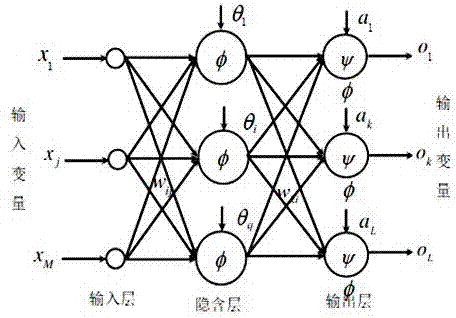

[0025] 1) Create a material quality assessment model, select an artificial neural network algorithm for reverse transfer, and construct a reverse traditional network model;

[0026] 2) Divide the collected historical sample information into two parts: training data and verification data;

[0027] 3) Use the training data to train the model to obtain the model weight parameters and adjustment factors; use the verification data to test and verify the model training results until the verification results conform to the collected information, so as to obtain the nonlinearity of material quality and quality inspection of influencing factors relation;

[0028] 4) Use the verified model and model parameters to predict the quality level of the material.

[0029] figure 1 It is a flow chart of material quality assessment based on machine learning.

[0030] details as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com