Movable defect detection structure based on double rails

A defect detection and track detection technology, applied in the field of detection systems, can solve problems such as the lack of a defect detection system, and achieve the effect of improving maintenance efficiency and achieving accurate detection and positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

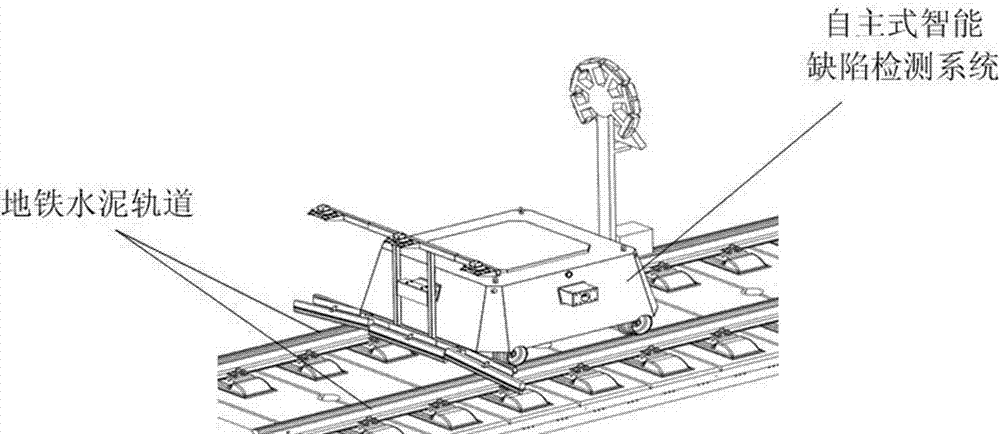

[0028] according to figure 1 As shown, the present invention discloses a movable defect detection structure based on double rails. The structure can move autonomously on the subway concrete track, and is equipped with a track detection system and a tunnel dome detection system. The detection robot can be remotely controlled by a remote terminal. Remote control operation, intelligent non-destructive testing, image acquisition and positioning of the subway cement track surface and tunnel dome, providing accurate positioning for later maintenance.

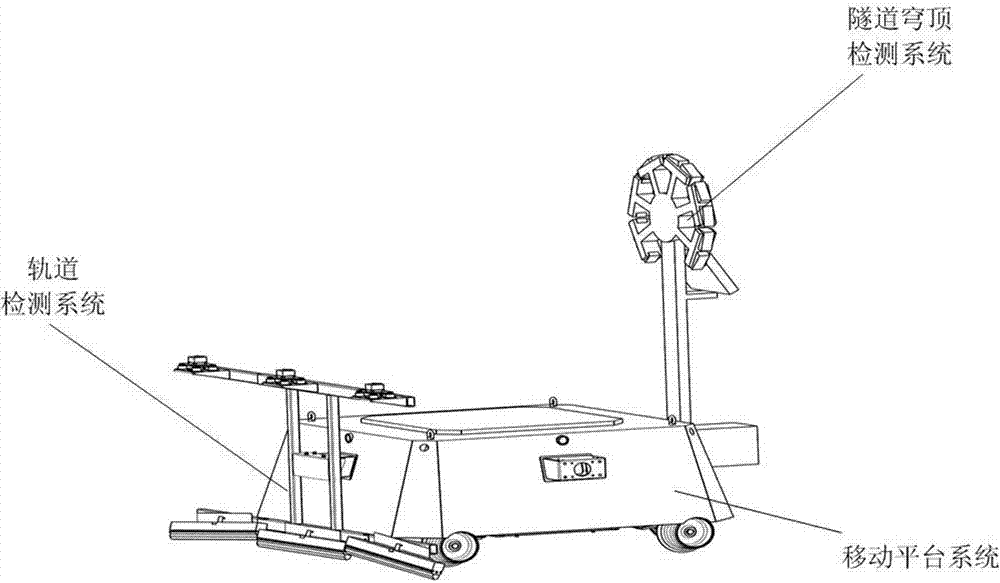

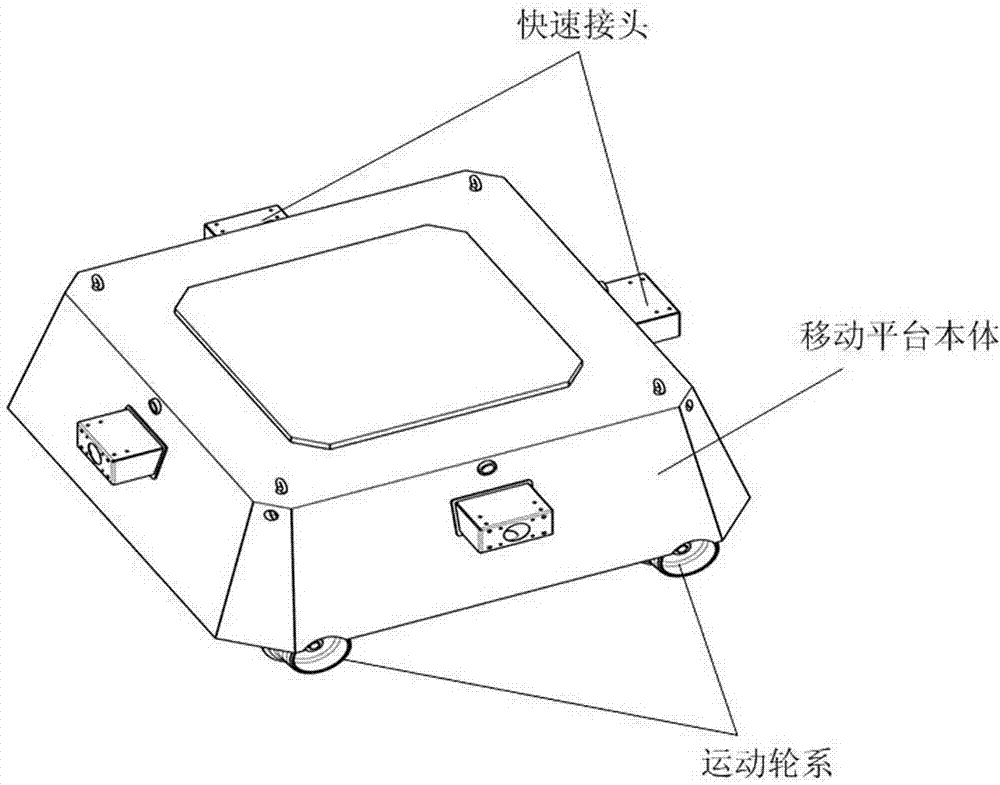

[0029] according to figure 2 As shown, the autonomous intelligent defect detection system consists of a mobile platform system, a track detection system and a tunnel dome detection system. The mobile platform system is equipped with a track detection system and a tunnel dome detection system to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com