Experiment device and method for measuring turbulent friction resistance of flat plate

A technology for measuring flat plates and experimental devices, which can be used in measuring devices, aerodynamic tests, and testing of machine/structural components. Large ground area and other problems, to achieve the effect of stable experimental smoke flow, reliable design principle, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

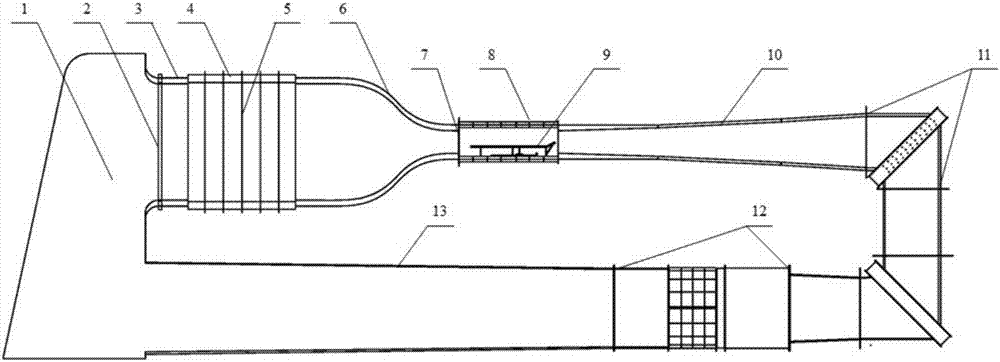

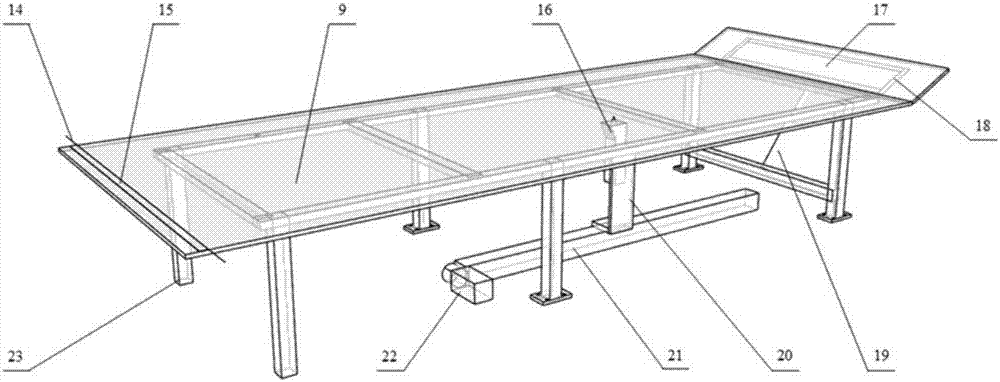

[0017] Attached below figure 1 and figure 2 And embodiment the present invention is described in more detail.

[0018] According to the experimental device for measuring flat turbulent frictional resistance provided by the invention, such as figure 1 , figure 2 As shown, it includes a smoke collection chamber 1, and an air channel formed by sequential connection of a gas collection section 3, a stable section 4, a contraction section 6, an experimental section 8, a diffusion section 10, a corner section 11, a power section 12, and an outlet section 13 , the smoke collection chamber is connected to the gas collection section and the outlet section to form a complete air circulation system, and the air flow direction is from the gas collection section to the outlet section through the entire air channel.

[0019] A smoke generator and a smoke diffusion fan are arranged in the smoke collection chamber 1, and a noise-absorbing net 2 is arranged vertically to the air flow dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com