Storage tank

A storage tank and tank body technology is applied in the field of sealing devices for storage tanks, which can solve problems such as safety accidents and low reliability, and achieve the effects of reliable sealing, low cost and reliable sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

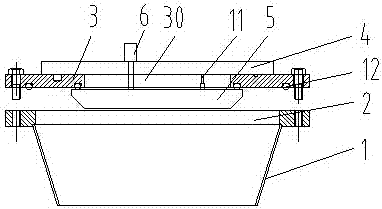

[0021] The invention as Figure 1-2 Shown, comprise the tank body 1 of top opening 2, the top of described tank body is provided with flange plate 3, and described flange plate has middle hole 30, and the aperture of described middle hole is less than the caliber of tank body top opening;

[0022] The top surface of the flange is provided with an upper cover plate 4, and the bottom surface is provided with a lower cover plate 5. The center lines of the upper cover plate, the middle hole and the lower cover plate are consistent, and the upper cover plate and the lower cover plate are respectively For closing the middle hole;

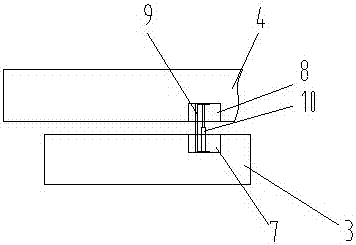

[0023] The top surface of the flange 3 is provided with an annular hole 1 7, and the upper cover plate 4 is provided with an annular hole 2 8, the annular hole 1 and the annular hole 2 are oppositely arranged, and the annular hole 1 and the annular hole 1 are arranged oppositely. The second is provided with an annular filter-9;

[0024] The section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com