Wheel-side reducer adopting grease separating lubrication

A wheel-side reducer and grease separation technology, applied in gear lubrication/cooling, gear transmission, belt/chain/gear, etc., can solve problems such as lubricating oil viscosity reduction, vibration, and lubricating oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments.

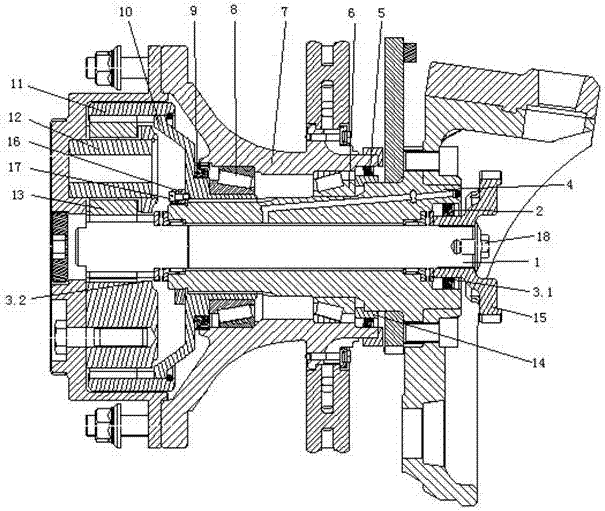

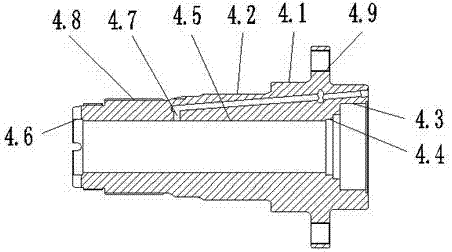

[0024] A grease-separated and lubricated wheel-side reducer, including planetary components, hubs and power input components; the input components include an input gear shaft 1, a shaft head 4 and an input flange 15. The input gear shaft 1 penetrates the center of the shaft head 4 and passes The first roller bearing 3.1 and the second roller bearing 3.2 are supported in the shaft head 4. The input flange 15 and the input gear shaft 1 are connected by splines and are fixed by the fastening screws 18; the planetary components include a plurality of planet wheels 13 , The planetary gear 13 is meshed and connected with the input gear shaft 1, a plurality of planetary gears 13 are correspondingly sleeved on the planetary gear shaft 12, a plurality of pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com