New Axial Impact Tool Based on Turbine and Cam

A technology of axial impact and turbine, applied in the direction of drilling tools, drilling equipment and methods, driving devices for combined rotary drilling, etc., can solve problems such as increased hardness and strength, complex working environment, and low rock breaking efficiency of the drill bit. Achieve the effect of increasing the service life and improving the rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

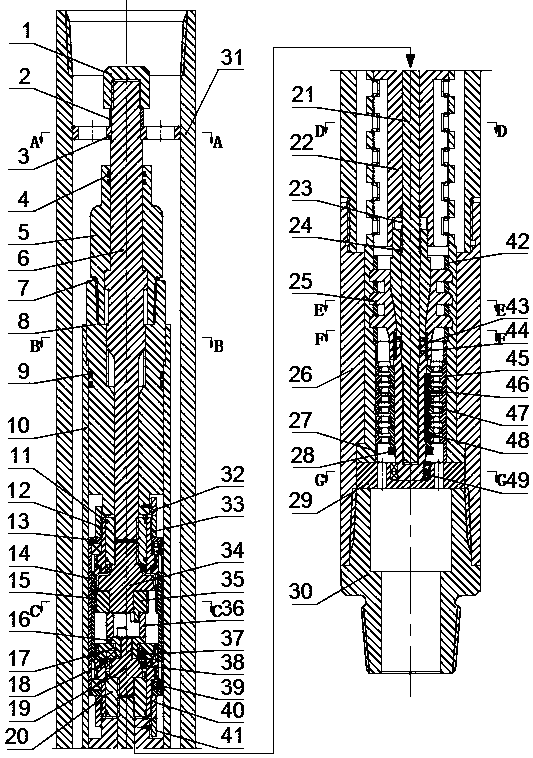

[0021] The present invention will be further described below in conjunction with accompanying drawing:

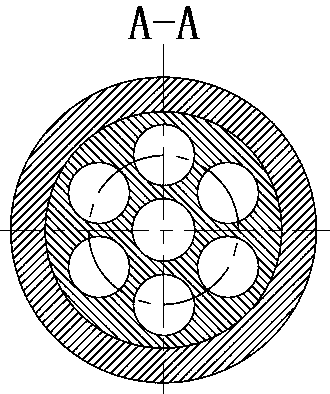

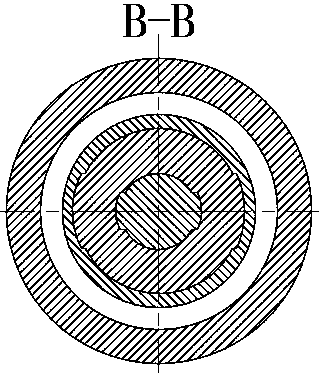

[0022] See attached figure 1 , a new type of axial impact tool based on a turbine and a cam, including an outer shell, an impact assembly, a reducer, a guide assembly, and a turbine assembly. It is characterized in that: the impact assembly, reducer, diversion assembly, turbine assembly; the impact assembly includes salvage shaft sleeve 1, limit sleeve a2, diversion sleeve a3, O-ring seal a4, upper impact cylinder 5, salvage shaft 6, O Type seal ring b7, lower impact cylinder 8, O-type seal ring c9, roller a32, O-type seal ring a4 is installed on the inner wall of upper impact cylinder 5, O-type seal ring c9 is installed on the outer wall of lower impact cylinder 8, and roller a32 is circumferentially spaced 120°evenly arranged at the front end of the lower impact cylinder 8, the upper impact cylinder 5 is loaded from the rear end of the salvage shaft 6, the lower impact c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com