Casement window hinge, manufacturing method of casement window hinge, and casement window using casement window hinge

A casement window and hinge technology, which is applied in the casement window hinge and its manufacturing field, can solve the problems of reduced bearing capacity of slide rails, low dimensional accuracy requirements, and falling off of stamping parts, and achieves fast positioning and assembly, and improves production efficiency. The effect of increasing the fixed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

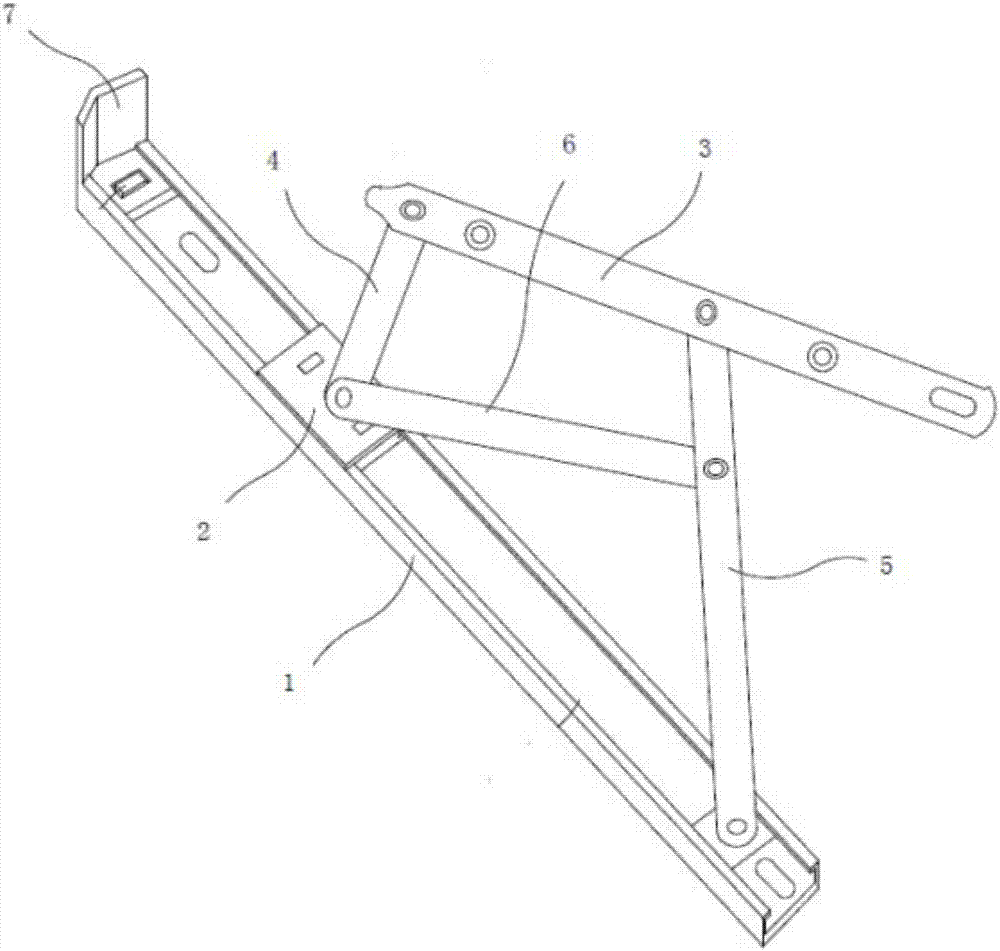

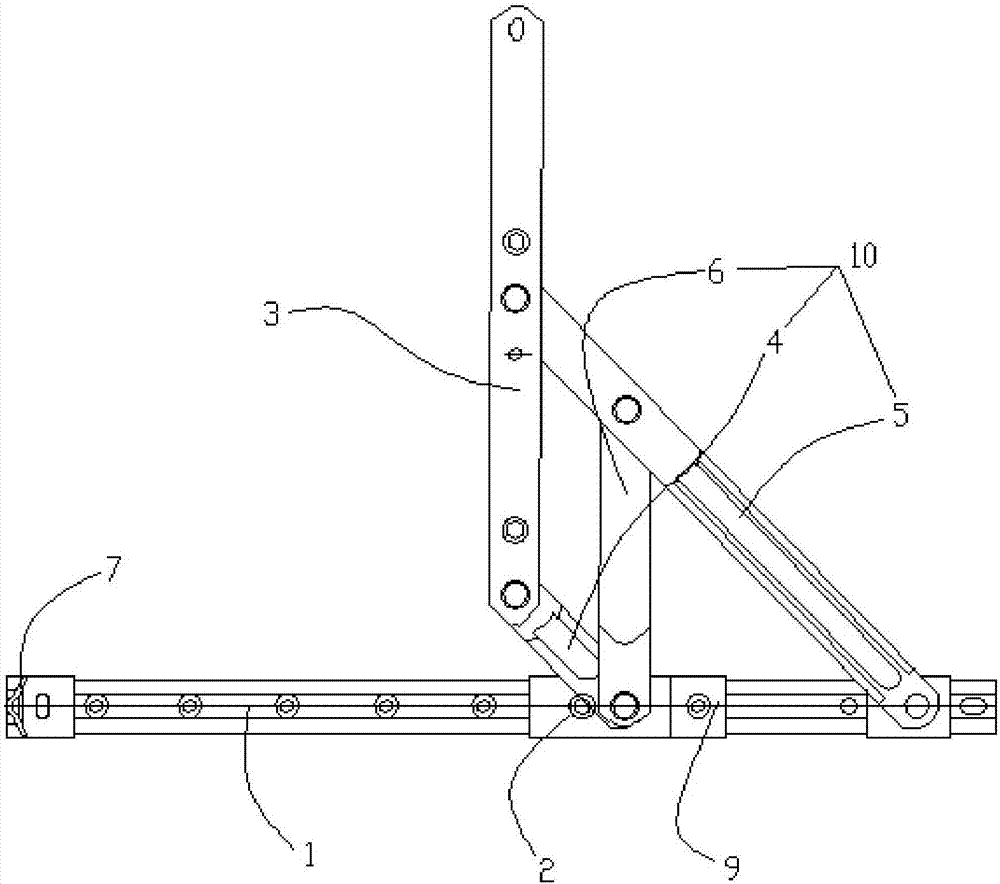

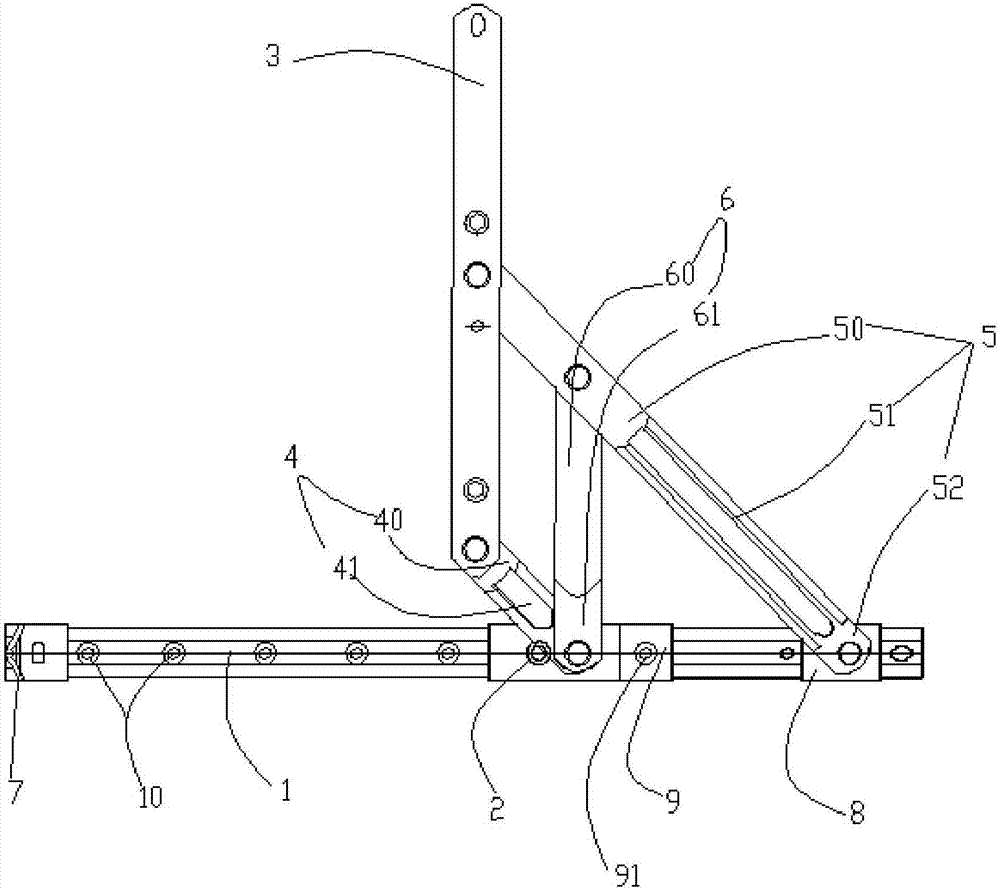

[0041] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0042] The specific embodiment of the present invention provides a casement window hinge.

[0043] Please refer to figure 2 , the casement window hinge includes a slide rail 1 , a pull rod 3 , a hinge fixing part 7 , a sliding part 2 and a connecting part 10 .

[0044] Described slide rail 1 is fixed on the bottom window frame of form, is generally fixed by screw. The slide rail 1 has a sliding groove 13 along the extending direction of the slide rail; wherein, a hinge fixing part 7 is fixed at one end of the slide rail 1; The sliding part 2 is fixed on the sliding rail 1 and can slide on the sliding rail 1 .

[0045] The pull rod 3 is rotationally fixed on the sliding part 2 through the connecting part 10, and when the sliding part 2 slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com