In-tunnel weak pressure sudden dropping and sudden expansion type jet flow stilling pool energy dissipation system

A stilling pool and sudden drop technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of large amount of engineering excavation, increased engineering difficulty, and poor economy, so as to ensure safe operation and reduce engineering excavation The effect of stable increase in quantity and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The engineering overview of embodiment 1 and comparative example 1 is as follows:

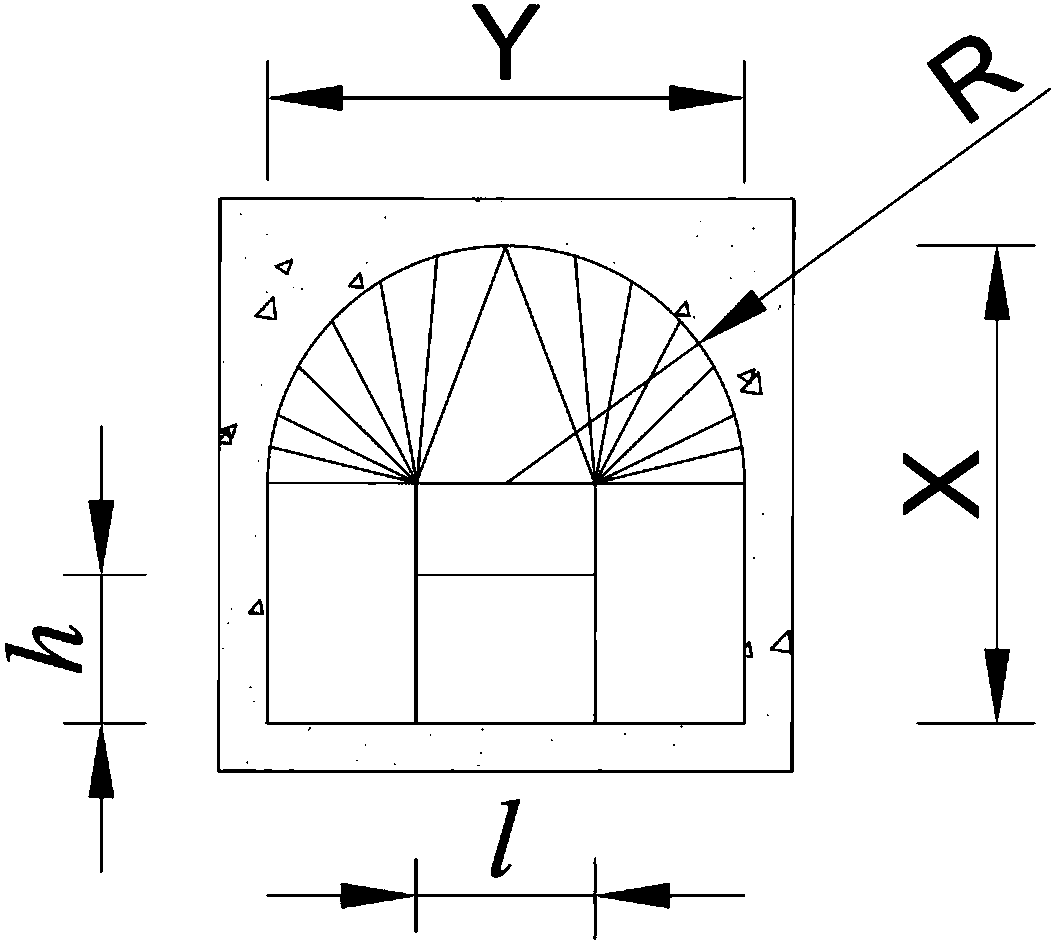

[0030] The flow tunnel is in the shape of a city gate, with a height of X = 16m, a width of Y = 16m, and a flood discharge of 1200m 3 / s.

[0031] Aiming at the above projects, two energy dissipation systems of Example 1 and Comparative Example 1 were used to carry out hydraulic model tests.

[0032] Example 1

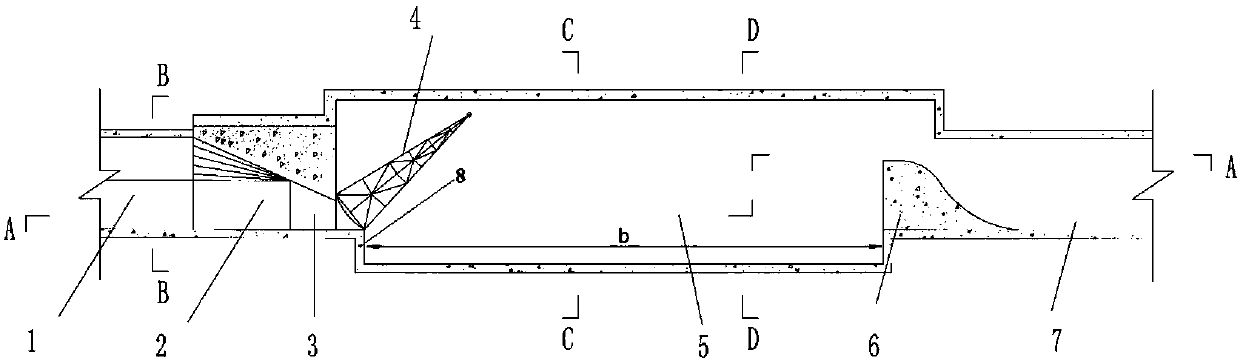

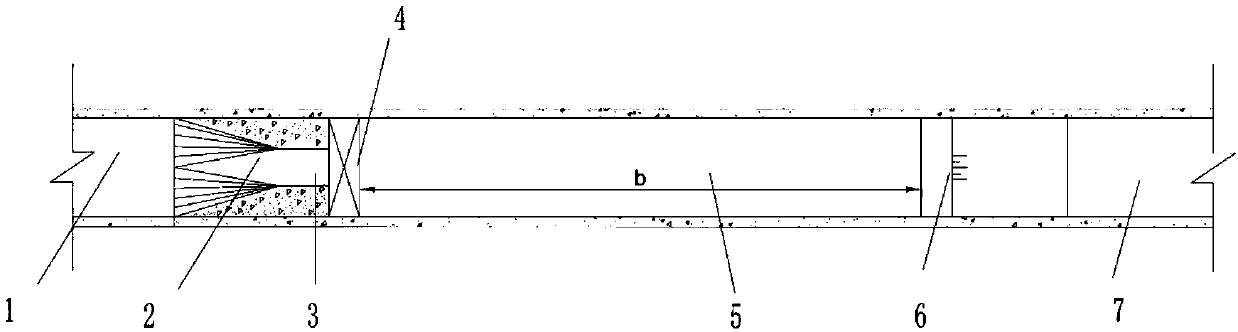

[0033] In this embodiment, the energy dissipation system of the jet stilling pool with weak pressure, sudden drop and sudden expansion in the cave is a single jet hole structure, and the structure is as follows Figure 1-5 As shown, from upstream to downstream, there are the jet hole section connected with the upstream tunnel section 1, the drop sill 8 arranged at the outlet of the jet hole section, the low-pressure stilling pool 5 connected with the drop sill, and the tail of the low-pressure stilling pool connected with The tail sill 6 of the downstream tunnel section 7 is p...

Embodiment 2

[0042] The engineering overview of embodiment 2 and comparative example 2 is as follows:

[0043] The flow tunnel is in the shape of a city gate, with a height of X = 19m, a width of Y = 17m, and a flood discharge of 1,800m 3 / s.

[0044] Aiming at the above projects, two energy dissipation systems of Example 2 and Comparative Example 2 were used to carry out hydraulic model tests.

[0045] Example 2

[0046] The energy dissipation system of the jet stilling pool with weak pressure, sudden drop and sudden expansion in the cave described in this embodiment is in the form of double jet holes, and the structure is as follows Figure 6-10 As shown, the two jet holes are arranged side by side with a distance of 5m. The shape and size of the two jet holes are the same. The top of the low-pressure stilling tank 5 is lined with reinforced concrete. All the other structures are with embodiment 1.

[0047] The dimensions of each part of the structure are as follows: the width of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com