Woven cloth edge cutting device of textile machine

A machine-spinning and edge-cutting technology, which is used in the cutting of textile materials, textiles and papermaking, can solve the problems of slow edge-cutting, high power consumption, and slow fabric production, so as to improve efficiency and speed, and improve cutting The effect of edge quality and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

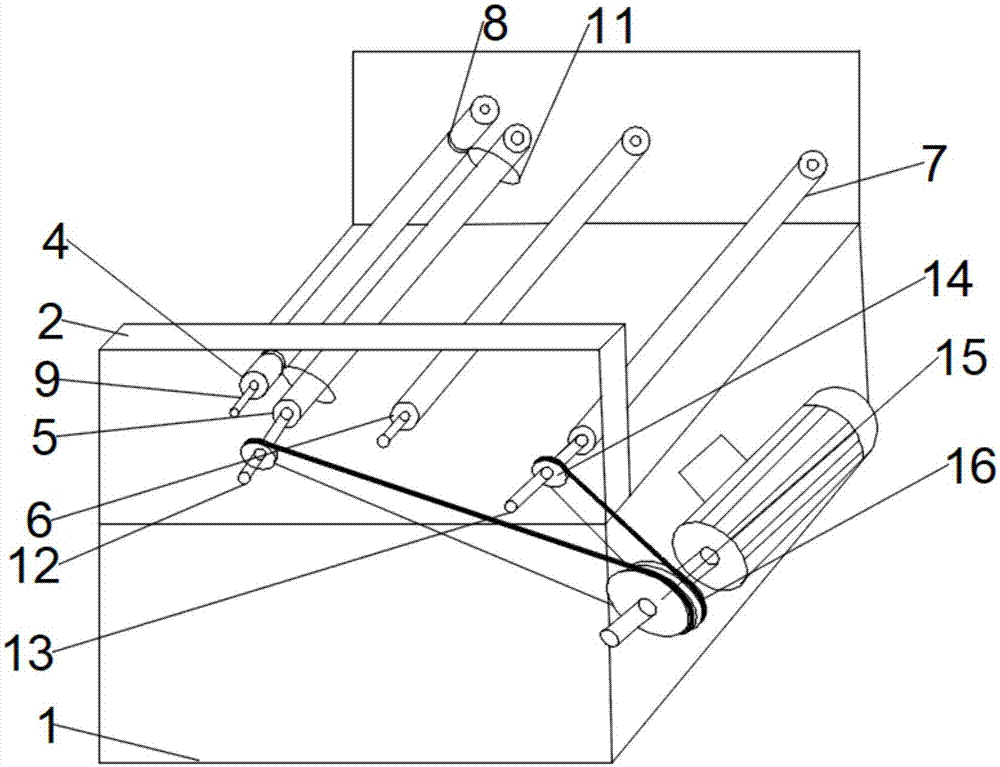

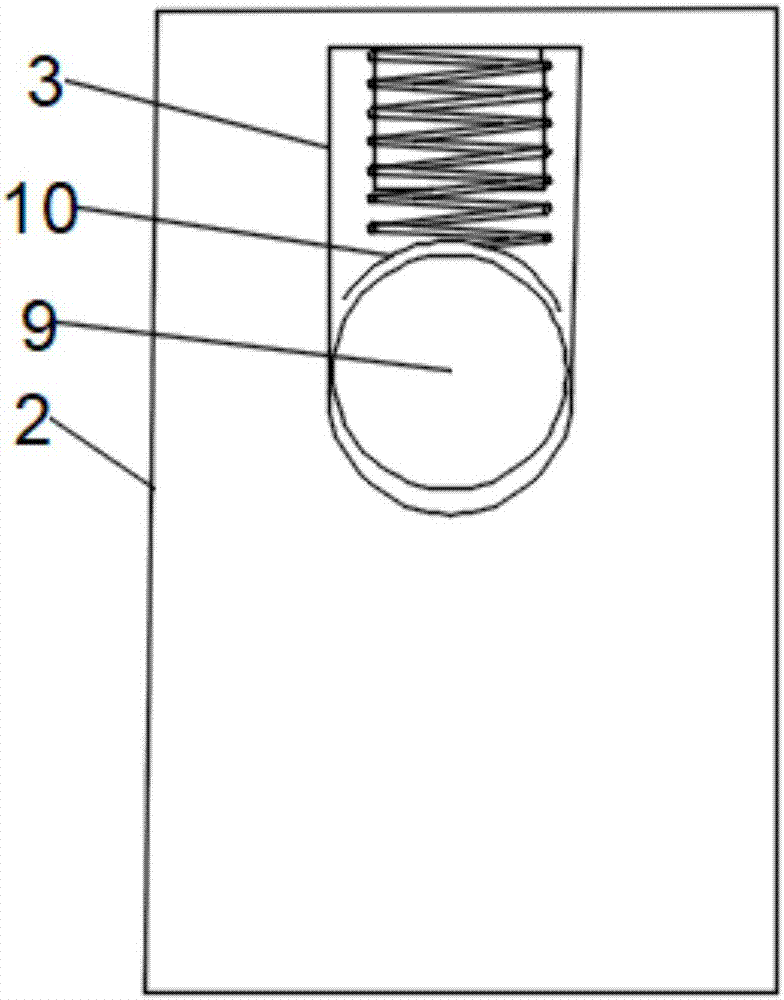

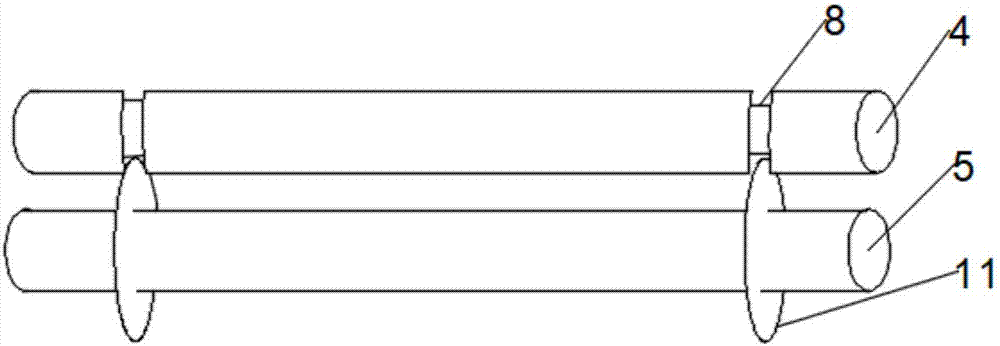

[0021] Such as Figure 1 to Figure 3 As shown, a kind of textile machine spun edge trimming device provided by the present invention comprises a bracket 1, two parallel mounting plates 2 are installed on the top of the bracket 1, and a plurality of mounting holes 3 are provided on the mounting plate 2. The hole 3 is used to install the compression wheel 4, the transmission wheel 5, the support wheel 6 and the cloth rolling wheel 7, and the compression wheel 4, the transmission wheel 5, the support wheel 7 are installed sequentially from left to right between the two mounting plates 2 The wheel 6, the cloth rolling wheel 7, and the pressing wheel 4 tightly press the cloth on the transmission wheel 5, so as to avoid the uneven cutting caused by the unevenness and tension of the cloth when it is trimmed, and the support wheel 6 makes the cloth completely out, so that the cloth comes out and is cut more smoothly, and the cloth roll wheel 7 is responsible for the roll-up of the clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com