Method for electroporation of Staphylococcus carnosus and its application

A technology of staphylococcus meatus and electrotransformation is applied in the field of electrotransformation of staphylococcus meatus, which can solve the problems of poor repeatability and low conversion rate, and achieve the effect of improving the electrotransformation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

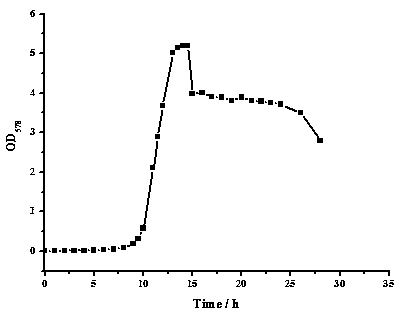

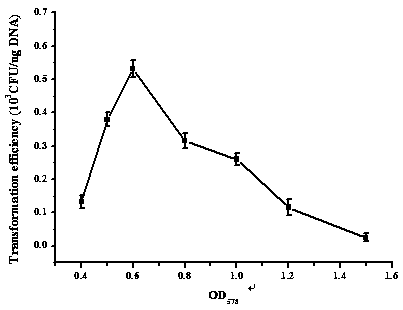

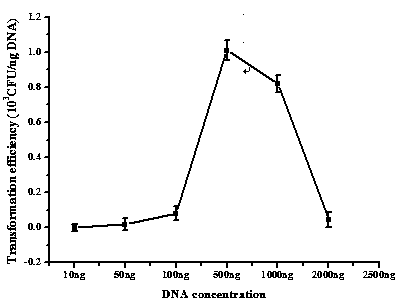

[0080] Optimization of Electrotransformation Conditions for Staphylococcus carnosus

[0081] 1. Plasmid extraction and quantitative detection

[0082] (1) Take 4 mL of the overnight bacterial culture, centrifuge at 12,000 rpm for 1 min, and discard the supernatant.

[0083] (2) Add 250 μL of solution (P1), use a pipette gun to blow and suck the bacterial pellet repeatedly to suspend it thoroughly.

[0084] (3) Add 250 μL solution II (P2), gently turn it up and down 6-8 times to fully lyse the bacteria, then add 350 μL solution III (P3), immediately turn it up and down gently 6-8 times, and centrifuge at 12000 rpm for 10 minutes.

[0085] (4) Add the supernatant collected in the previous step to the adsorption column, centrifuge at 12000rpm for 1min, discard the waste liquid in the collection tube, and put the adsorption column back into the collection tube.

[0086] (5) Add 700 μL of rinse solution (PW), centrifuge at 12,000 rpm for 1 min, discard the waste liquid, and pu...

Embodiment 2

[0108] Optimization of Electrotransformation Conditions for Staphylococcus carnosus

[0109] The difference between this example and Example 1 lies in that the selected shuttle vector is different, and pBT2-ET-4C-5R-EGFP is used in Example 2, and the rest of the experimental steps and conditions are the same.

[0110] 1. Plasmid extraction and quantitative detection

[0111] (1) Take 4 mL of the overnight bacterial culture, centrifuge at 12,000 rpm for 1 min, and discard the supernatant.

[0112] (2) Add 250 μL of solution (P1), use a pipette gun to blow and suck the bacterial pellet repeatedly to suspend it thoroughly.

[0113] (3) Add 250 μL solution II (P2), gently turn it up and down 6-8 times to fully lyse the bacteria, then add 350 μL solution III (P3), immediately turn it up and down gently 6-8 times, and centrifuge at 12000 rpm for 10 minutes.

[0114] (4) Add the supernatant collected in the previous step into the adsorption column, centrifuge at 12000rpm for 1mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com