Recycling dyeing process of nylon fabric printing and dyeing wastewater

A technology for nylon fabrics and printing and dyeing wastewater, which is applied in textile industry wastewater treatment, dyeing, textiles and papermaking, etc. It can solve the problems of high cost of biochemical methods and unsatisfactory CODcr removal rate, so as to save steam and improve dyeing production capacity and efficiency , the effect of shortening the dyeing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 1. Preparation of wastewater treatment agent WFS088:

[0031] 1. Formula and dosage

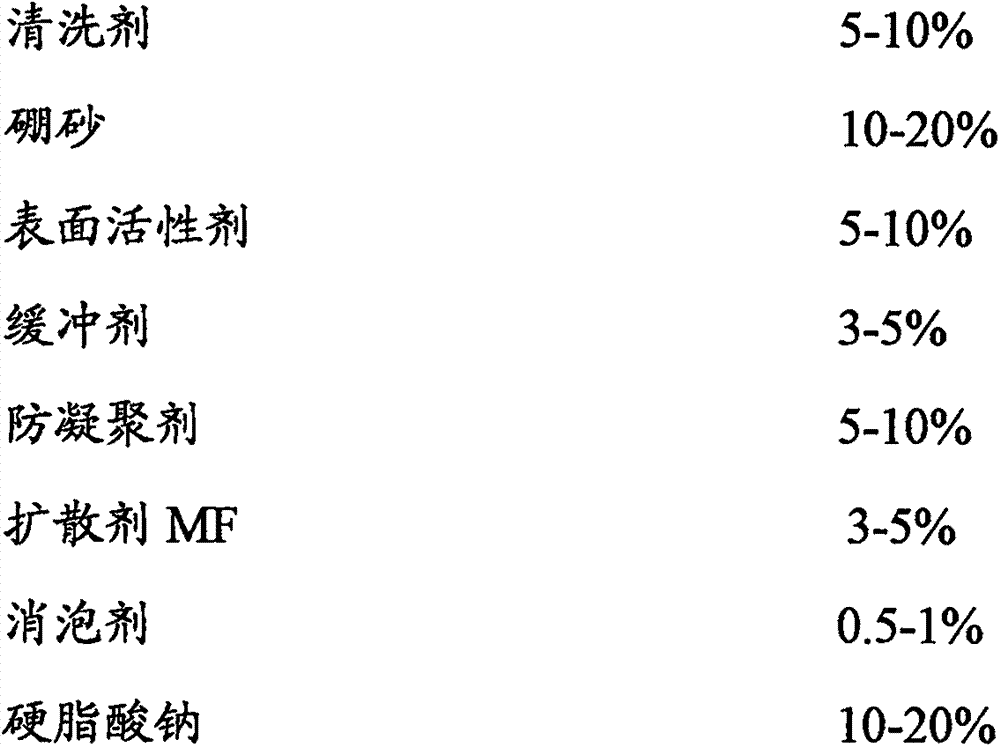

[0032] Wastewater treatment agent WFS088 includes raw materials in the following weight percentages:

[0033]

[0034]

[0035] 2. Preparation process:

[0036]Dilute sodium stearate with water first to prepare an aqueous solution with a mass concentration of 15%, then transfer the aqueous solution to a reaction kettle, add surfactants according to weight percentages, heat to 70°C, and then sequentially add cleaning agents according to weight percentages agent and borax, fully stirred and mixed, cooled to 40°C, and then added defoamer, diffusing agent MF, buffer and anti-coagulant in sequence according to the percentage by weight, after the foam was naturally eliminated, finally added water and fully stirred and mixed, that is, Wastewater treatment agent WFS088 was obtained;

[0037] 2. Preparation of special surfactant WFS099

[0038] 1. Formula and dosage

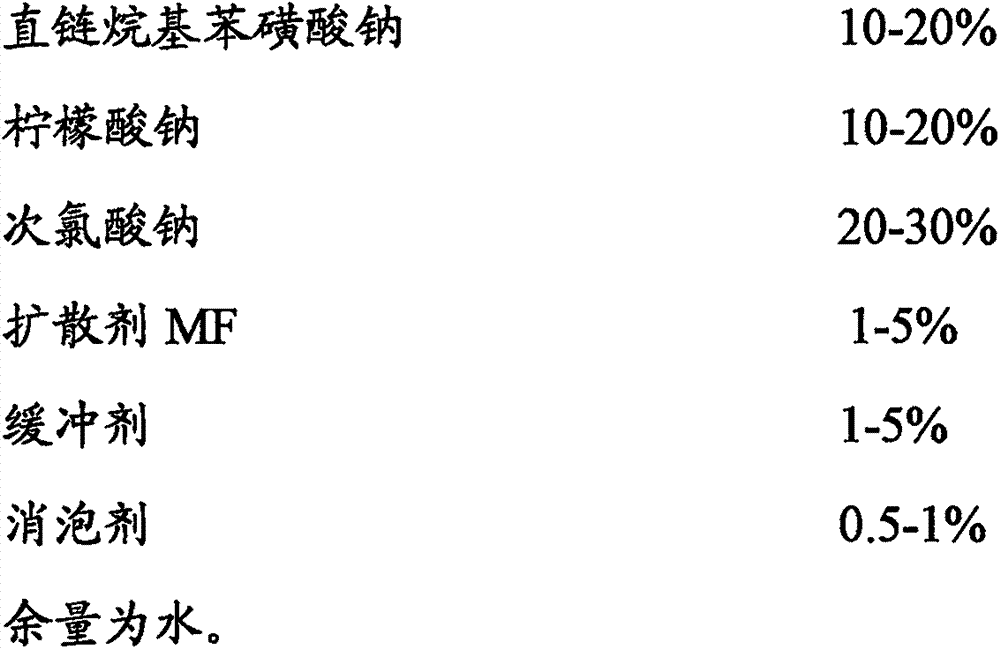

[0039] Special ...

Embodiment 1

[0044] A kind of nylon fabric printing and dyeing wastewater circulation dyeing process, comprises the following process steps:

[0045] (1) First check the dyeing machine to ensure that the dyeing machine is operating normally, and prepare the required dyes and dyeing auxiliaries according to the process requirements;

[0046] (2) Then calculate the required amount of water according to the requirements of the process bath ratio = 1:9 and the weight of the dyed fabric (kg), and directly add the collected printing and dyeing wastewater into the dyeing machine at 70 °C without cooling down, and then put it into the dyeing machine. Run the nylon fabric to be dyed in the dyeing machine cylinder for 3 to 4 minutes, so that the nylon fabric can be evenly soaked;

[0047] (3) Then add waste water treatment agent WFS088, special surfactant WFS099 and dyeing auxiliaries to the printing and dyeing wastewater in the dyeing machine, and add the weighed required dyes according to the dyei...

Embodiment 2

[0054] A kind of nylon fabric printing and dyeing wastewater circulation dyeing process, comprises the following process steps:

[0055] (1) First check the dyeing machine to ensure that the dyeing machine is operating normally, and prepare the required dyes and dyeing auxiliaries according to the process requirements;

[0056] (2) Then calculate the required amount of water according to the requirements of the process bath ratio = 1:8 and the weight of the dyed fabric (kg), and directly add the collected printing and dyeing wastewater into the dyeing machine at 60 ° C without cooling down, and then enter the waiting room Dye the nylon fabric, make it run in the dyeing machine cylinder for 3-4 minutes, so that the nylon fabric can be soaked evenly;

[0057] (3) Then add waste water treatment agent WFS088, special surfactant WFS099 and dyeing auxiliaries to the printing and dyeing wastewater in the dyeing machine, and add the weighed required dyes according to the dyeing needs;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com