Zero-tension cloth loosening machine

A cloth loosening machine, zero tension technology, applied in the direction of folding thin materials, thin material processing, transportation and packaging, etc., can solve the problems of cluttered cloth, low work efficiency, large labor consumption, etc., to improve work efficiency , to ensure continuous work and reduce the effect of manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

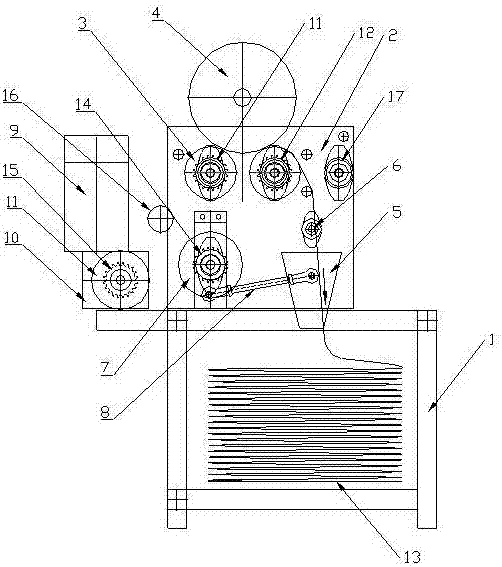

[0022] Such as figure 1 A zero-tension loosening machine is shown, which is used to unwind and loosen the cloth roll 3, including

[0023] A loose cloth support 1, the loose cloth support 1 is a frame structure composed of several horizontal bars and longitudinal bars.

[0024] A cloth releasing unit, which is installed on the upper end of the loose cloth support 1, includes a pair of symmetrically arranged cloth releasing support plates 2, and a pair of horizontally arranged cloth releasing rollers arranged side by side between the two cloth releasing support plates 2 3, and the two cloth release rollers 3 extend along the width direction of the cloth roll 4, there is a gap between the two cloth release rollers 3, the cloth roll 4 is placed above the two cloth release rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com