Full-automatic solid particle distributing device

A technology of solid particle and material distributing device, which is applied in the directions of packaging, loading/unloading, transportation and packaging, etc. It can solve problems affecting work efficiency, uneven feeding, poor automation, etc., and achieve guaranteed results and timely, strong automation, The effect of improving operational efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

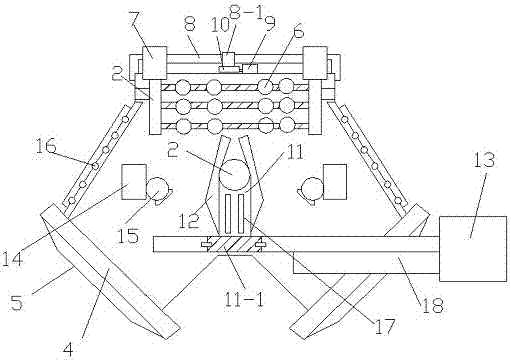

[0012] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0013] Such as figure 1 As shown: a fully automatic solid particle material distribution device in this embodiment, including a material distribution bin 1; a drum 2 and a valve shaft 3 are sequentially arranged in the material distribution bin 1 from top to bottom.

[0014] The bottom of the distribution bin 1 is respectively provided with two mutually symmetrical discharge ports 4; each of the discharge ports 4 is provided with a sensing valve 5; the drum 2 is sequentially provided with several stirring shafts 6 The two ends of the rotating cylinder 2 mesh with the mating wheels 7, wherein each of the mating wheels 7 is fixed on the rotating shaft 8; wherein the motor 9 is connected and fixed with the driving wheel 8-1 on the rotating shaft 8 through the gear 10 ; wherein the material distribution plate 11 is fixed on the valve shaft 3 and the two ends are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com