A control method for a turning and deviation correcting conveying device

A conveying device and control method technology, which is applied to conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of reduced production efficiency, easy air suction, and inability to achieve precise alignment of materials, and achieves turning and pushing processes. Simple, simple centering process for the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

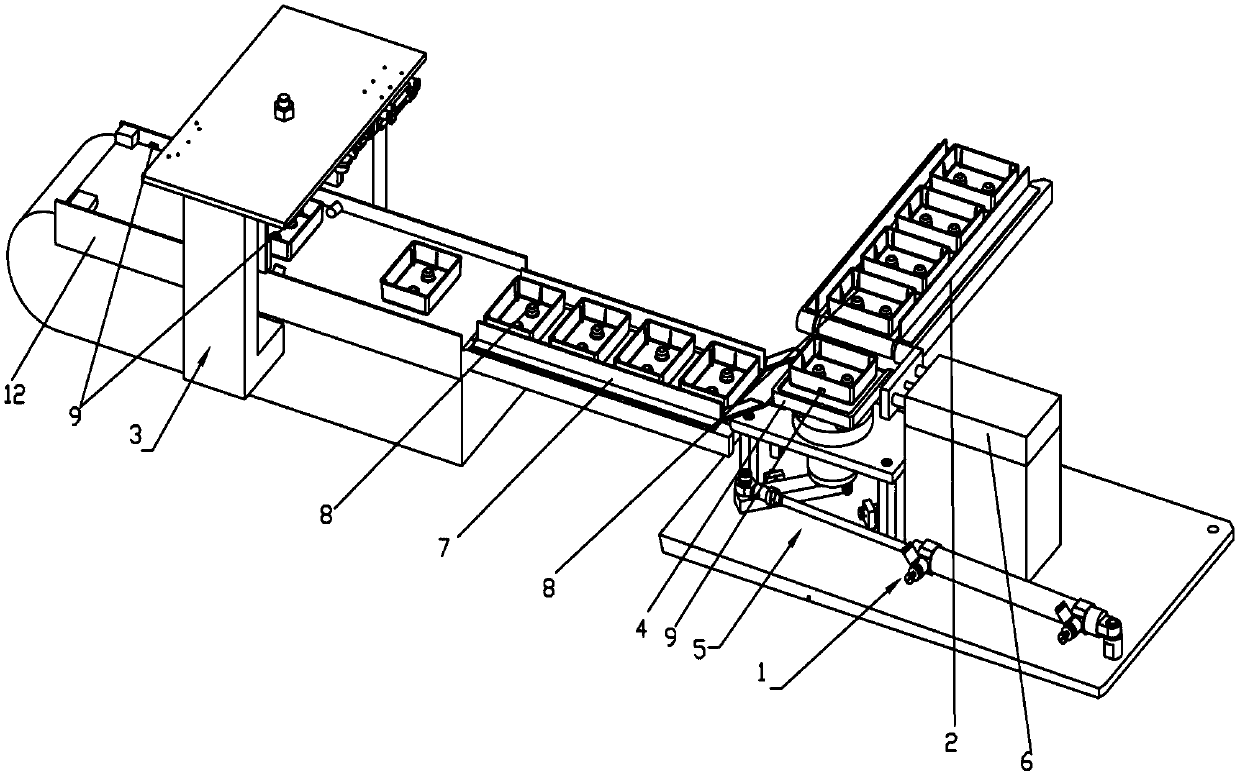

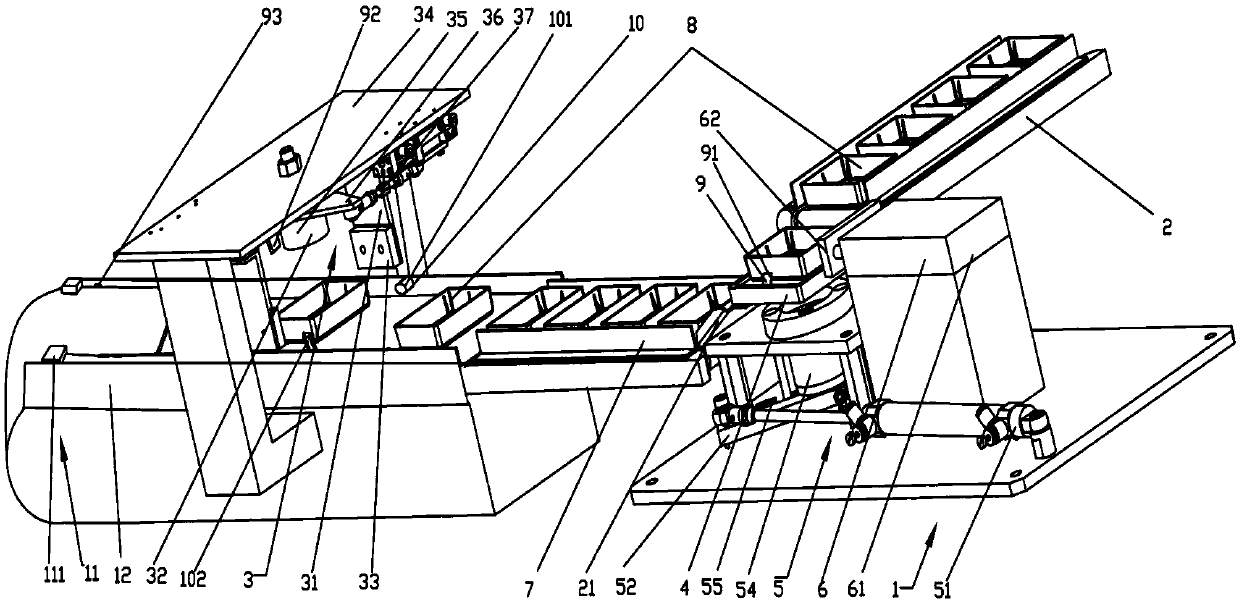

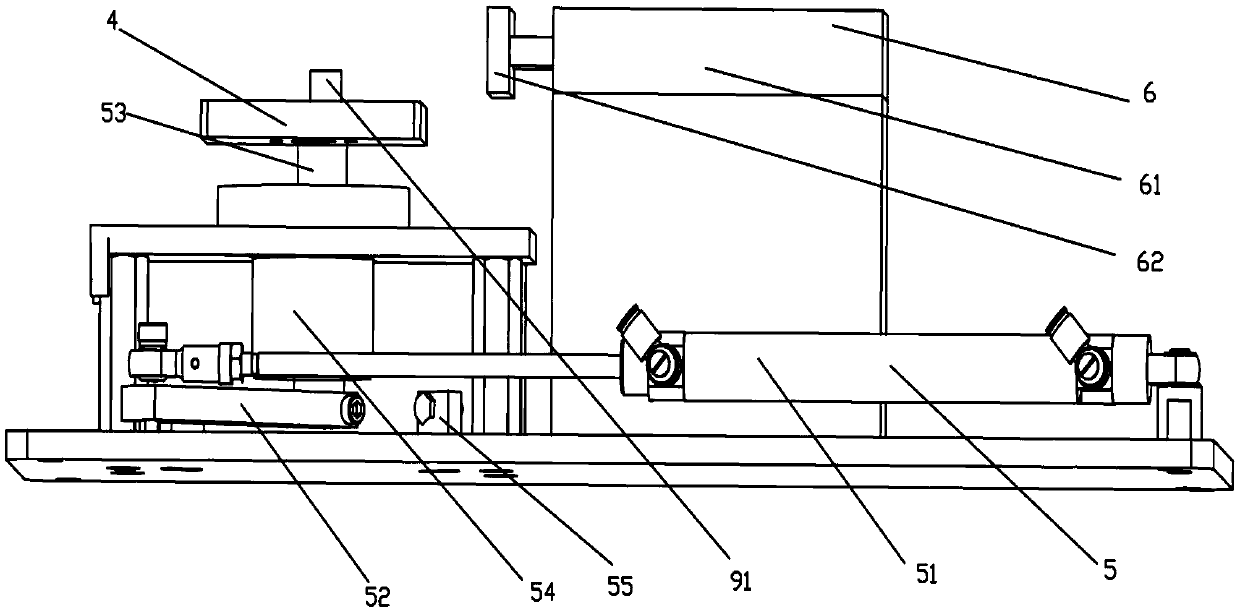

[0023] according to figure 1 , a conveying device for corner correction, including a conveying mechanism, a steering mechanism 1 and a centering mechanism 3, the conveying mechanism includes a first conveyor belt 2, a second conveyor belt 7 and a third conveyor belt 12, the first conveyor belt 2 and the second conveyor belt The conveyor belt 7 is arranged at 90 degrees, the centering mechanism 3 is arranged at the upper end of the third conveyor belt 12 , and the third conveyor belt 12 is arranged along the extending direction of the second conveyor belt 7 . The steering mechanism 1 includes a swing platform 4, a rotary machine 5 that drives the swing platform 4 to rotate, and a pusher 6 that pushes the workpiece 8; the steering mechanism 1 accepts the workpiece 8 sent b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com