Automatic fire extinguishing device for kitchen exhaust hood

An automatic fire extinguishing and fume hood technology, applied in fire rescue and other directions, can solve the problems of inability, no automatic fire extinguishing device, access to others, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

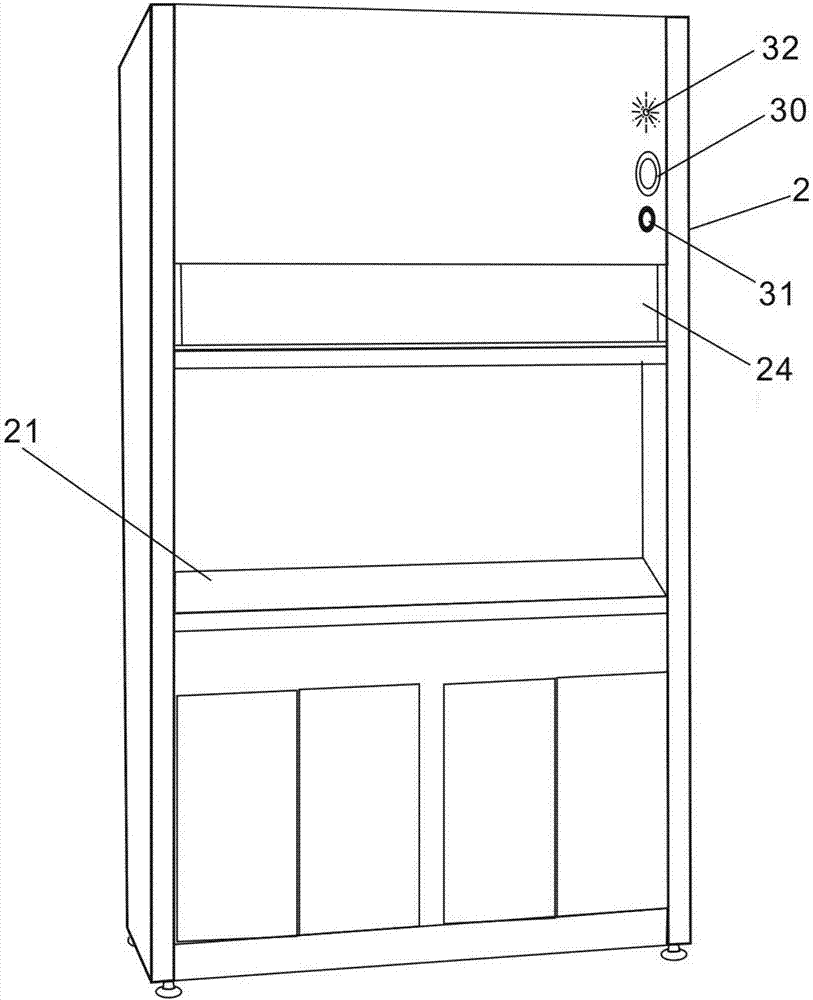

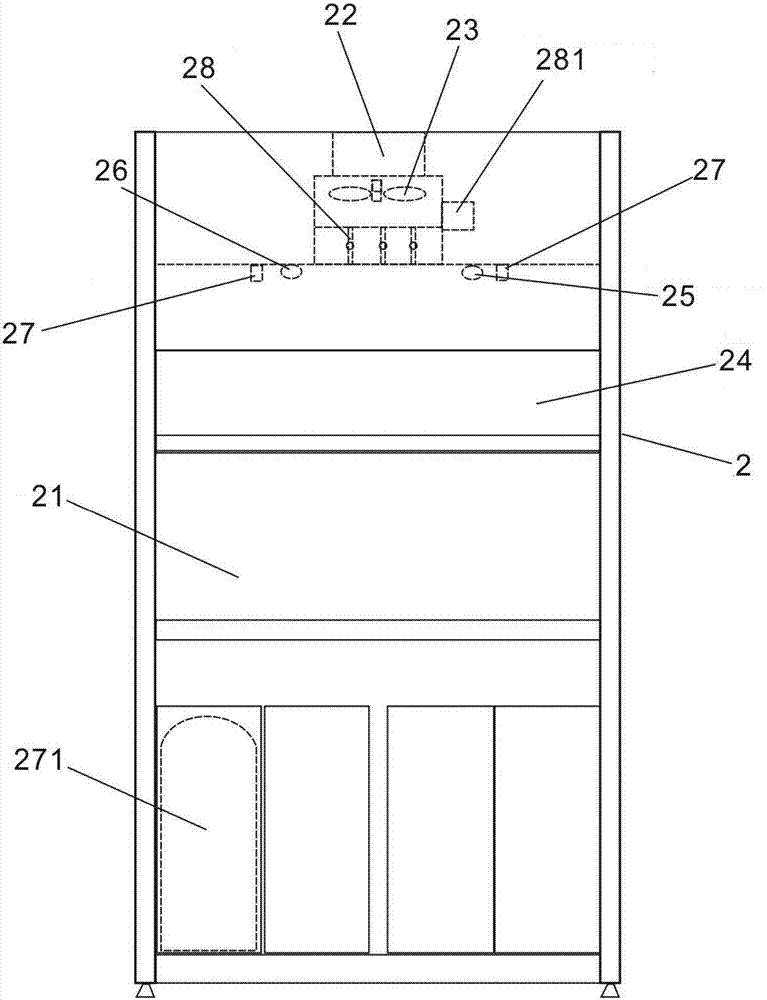

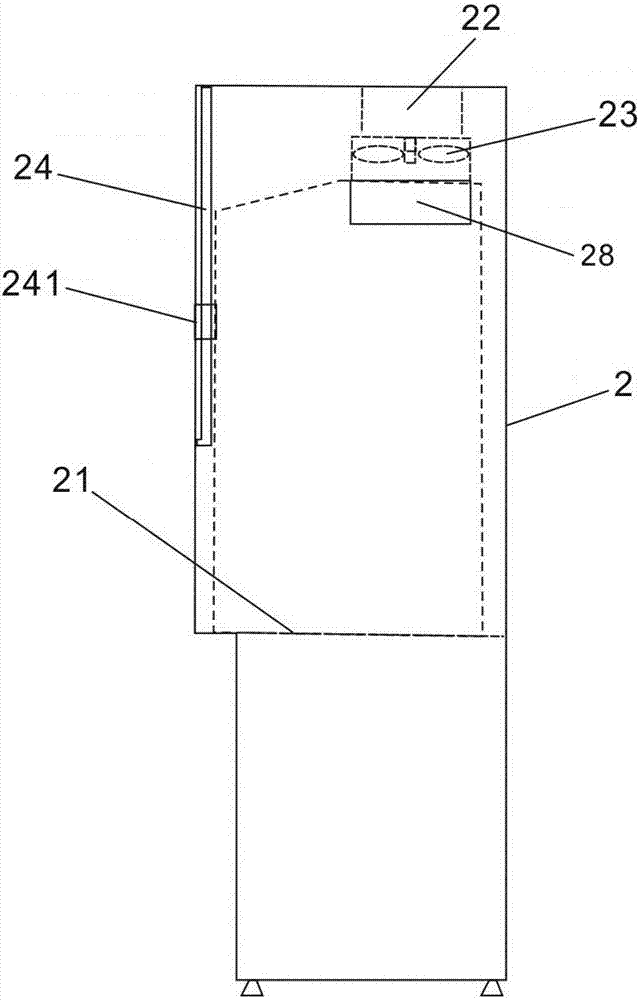

[0026] Such as figure 1 and figure 2 shown and combined with image 3 and Figure 4 The main components of the oil fume hood automatic fire extinguishing device are a cabinet 2 with a workbench 21, a ventilation pipe 22 and a ventilation device 23 near the opening of the ventilation pipe are installed on the workbench, and a movable window panel assembly 24 is installed in front of the ventilation device. The top edge of the workbench 21 is equipped with a first detection element 25 (which can be a flame detector or other detectors for detecting flames), a second detection element (which can be a smoke or temperature detector) and an automatic fire extinguisher connected to the cylinder cylinder 271. Device, the front end (or rear end) of ventilator 23 is equipped with the fire damper 28 that is driven by first driving device 281.

[0027] Such as figure 1 and figure 2 shown and combined with image 3 and Figure 4 , the first detection element 25, the second detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com