Charging module and charger employing same

A charging module and charging machine technology, which is applied in the modification of power electronics, battery circuit devices, current collectors, etc., can solve the problem of overheating of the charging module, and achieve the effect of prolonging the service life, ensuring normal operation, and avoiding uneven heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but not limited thereto.

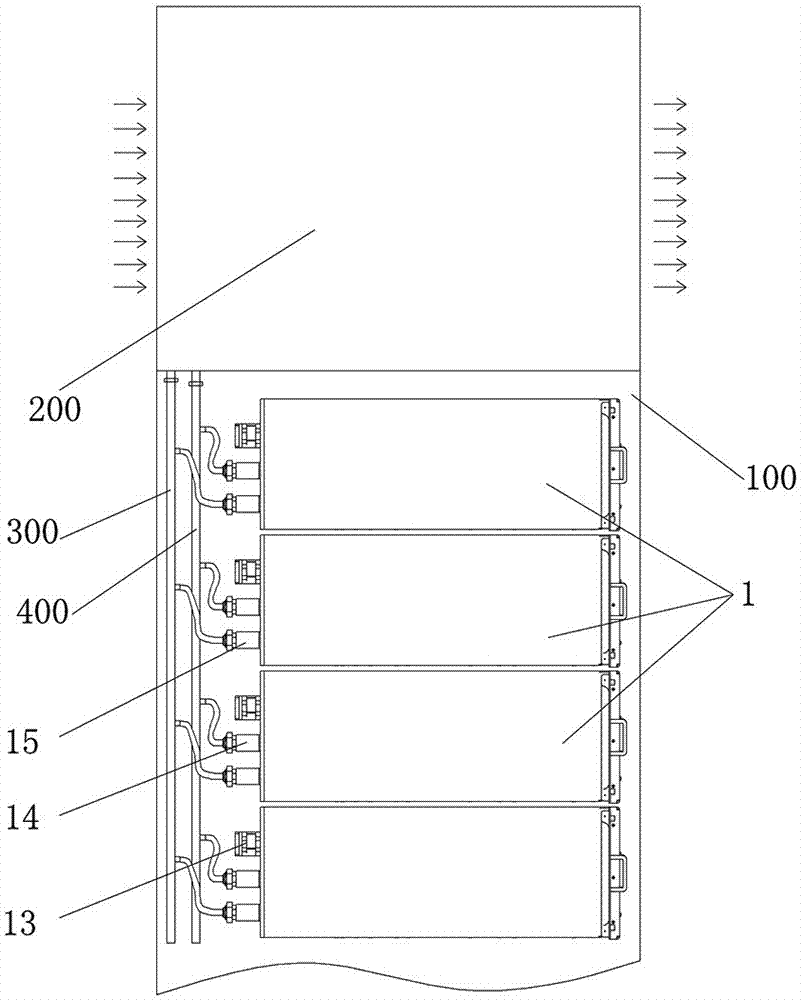

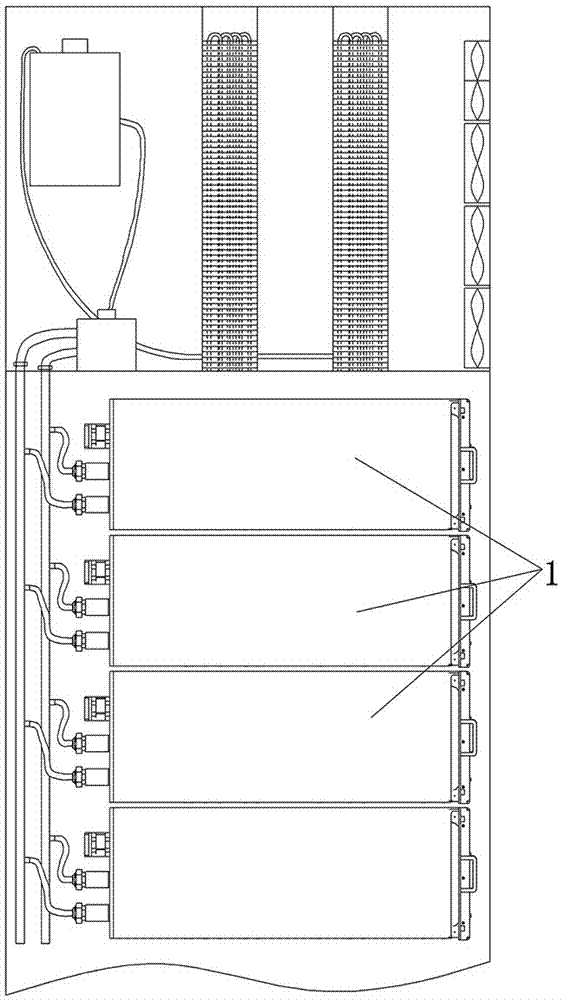

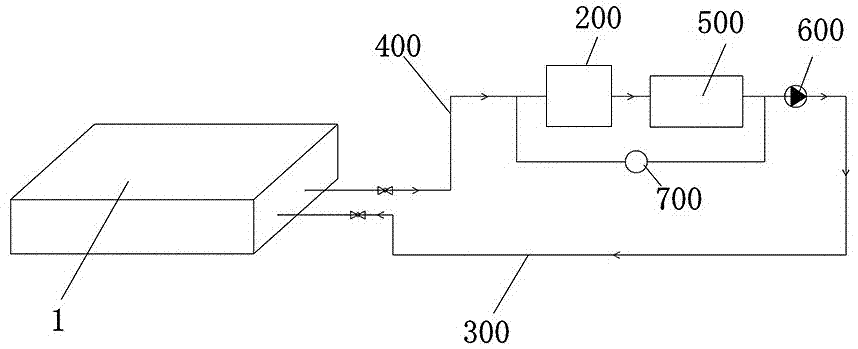

[0039] The specific embodiment of charger provided by the present invention, as Figure 1 to Figure 17 As shown, the overall structure of the charger in this embodiment is as figure 1 with figure 2 As shown, the charger includes a frame 100, on which a plurality of charging modules 1 are arranged in sequence along the up and down direction, and the rear end of each charging module 1 is respectively provided with a liquid cooling structure corresponding to the charging module. The liquid inlet connector 15 and the liquid outlet connector 14 here are preferably waterway quick-plug connectors. Correspondingly, the rear end of the charging module 1 is also provided with a connection terminal 13 . In order to facilitate installation and connection, and to improve the liquid cooling effect of each module, a centralized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com