Radiator for debugging circuit board

A technology of heat dissipation device and circuit board, applied in the direction of cooling/ventilation/heating transformation, can solve the problems of long time, large heat generation, affecting the performance of the circuit board, etc., to achieve the effect of easy debugging and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

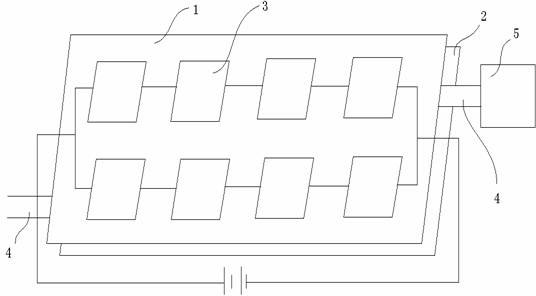

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] like figure 1 As shown, a circuit board cooling device includes an aluminum cooling plate base 1, a water pipe base 2, a cooling plate 3, a water pipe 4, a water pump 5 and a DC power supply; the cooling plate 3 is attached to the cooling plate base 1 Surface, and connected with the DC power supply, the water pipe 4 is connected with the water pump 5, and is installed between the refrigerating plate base 1 and the water pipe base 2. The water pipe 4 is fixed between the cooling plate base 1 and the water pipe base 2 in a sinusoidal waveform, and the cooling plate 3 is attached to the upper surface of the cooling plate base 1 in a combination of series and parallel connection.

[0012] When debugging the circuit board, place the circuit board on the refrigerating sheet 3, connect the refrigerating sheet 3 to the DC power supply, turn on the water pump 5, make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com