Liquid crystal display device production line test result storage method

A liquid crystal display and test result technology, applied to static indicators, instruments, etc., can solve the problems of high cost of code reading equipment, easy to read wrong barcodes, and lower error code rate, so as to shorten the burning time, improve efficiency, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

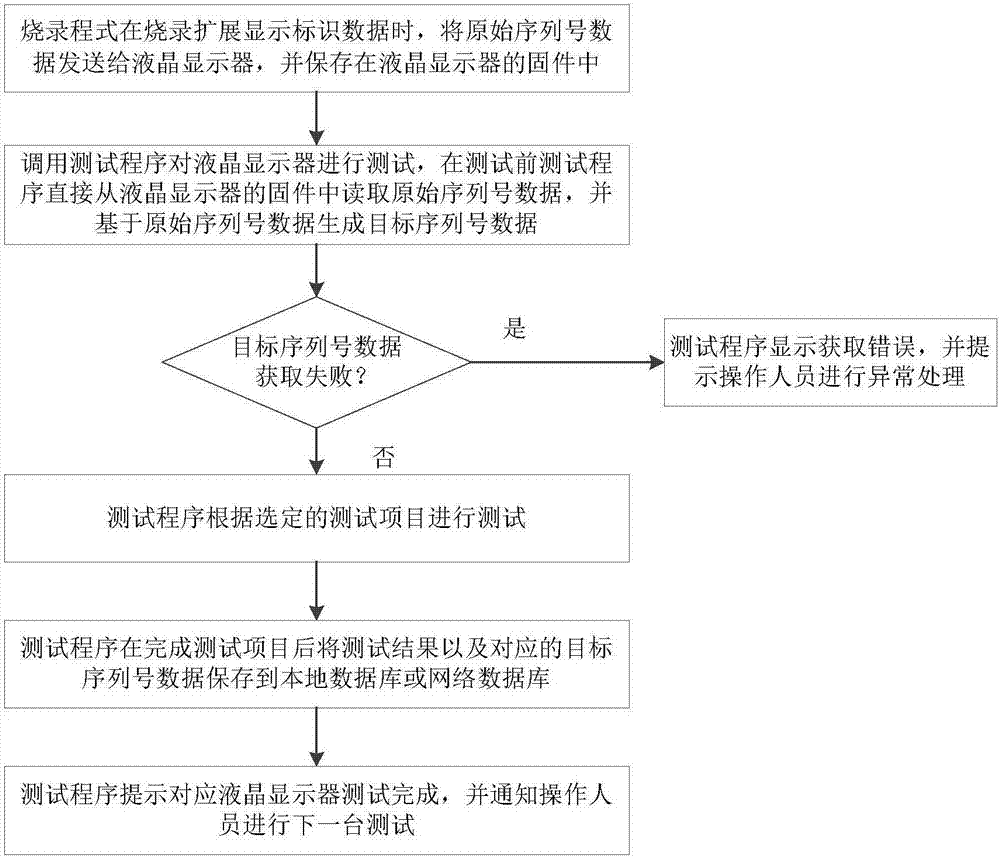

[0019] Such as figure 1 Shown, a kind of liquid crystal display production line test result preservation method of the present invention, it comprises the following steps:

[0020] 1) When the burning program burns the extended display identification data (EDID), it sends the original serial number (SN) data to the LCD and saves it in the firmware of the LCD; specifically, at the station where the EDID is burned , you can use a code reading gun to read the code, and all or part of the serial number data is saved in the EDID, which meets the premise of the test program to read the original serial number data.

[0021] 2) calling the test program to test the liquid crystal display, the test program directly reads the original serial number data from the firmware of the liquid crystal display before the test, and generates the target serial number data based on the original serial number data;

[0022] 3) When the acquisition of the target serial number data fails, the test prog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com