Torsion resistance fiber cable

A fiber optic cable and anti-twist technology, which is applied in the field of optical fiber, can solve the problems of fiber optic cable torsion damage, etc., and achieve the effect of improving the anti-twist effect, good reliability, and firm closure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

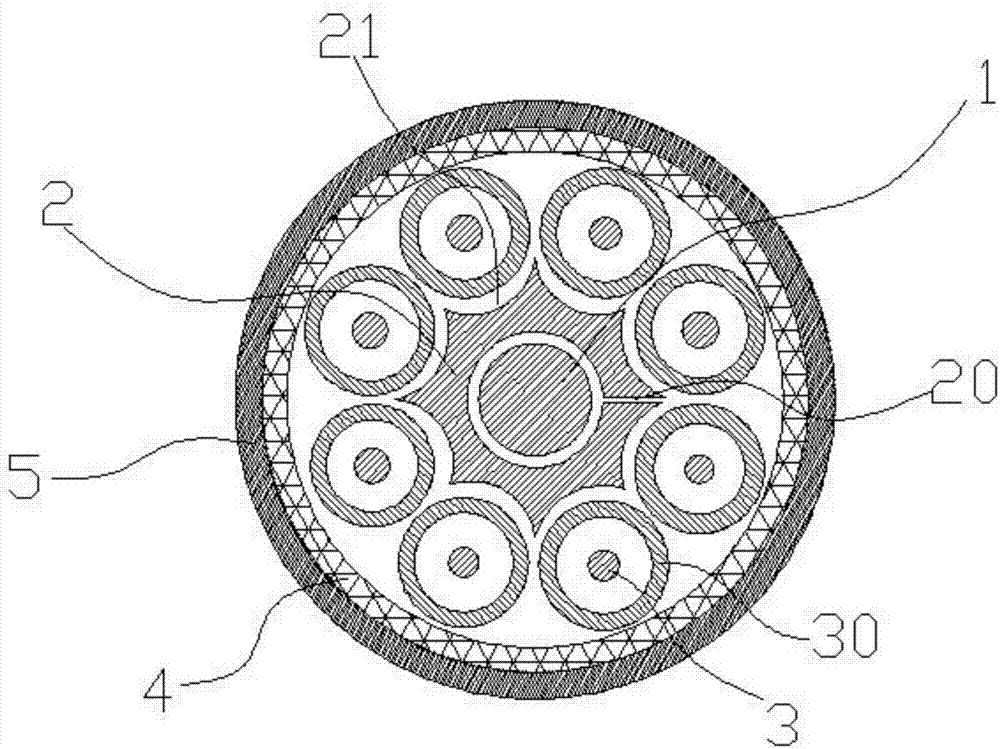

[0022] Example 1: A tensile torsion fiber optic cable

[0023] See figure 1 , Including a central reinforcement core 1, a tensile and torsion member 2 is sheathed outside the central reinforcement core 1, and the tensile and torsion member 2 is a sleeve structure that is arranged concentrically with the central reinforcement core 1 , And the sleeve structure is provided with a gap 20 along the length direction. The gap 20 is opened from the outer surface of the sleeve structure to the inner surface of the sleeve structure, and the outer surface of the sleeve structure is evenly spaced along the circumferential direction. There are two grooves 21, each groove 21 is arranged from the inside to the outside, and each groove 21 is provided with an inner insulating sheath 30, and each inner insulating sheath 30 is provided with an optical fiber 3, therefore, There are eight inner insulating sheaths 30 with optical fibers 3, and the centers of the circles where the eight optical fibers ...

Embodiment 2

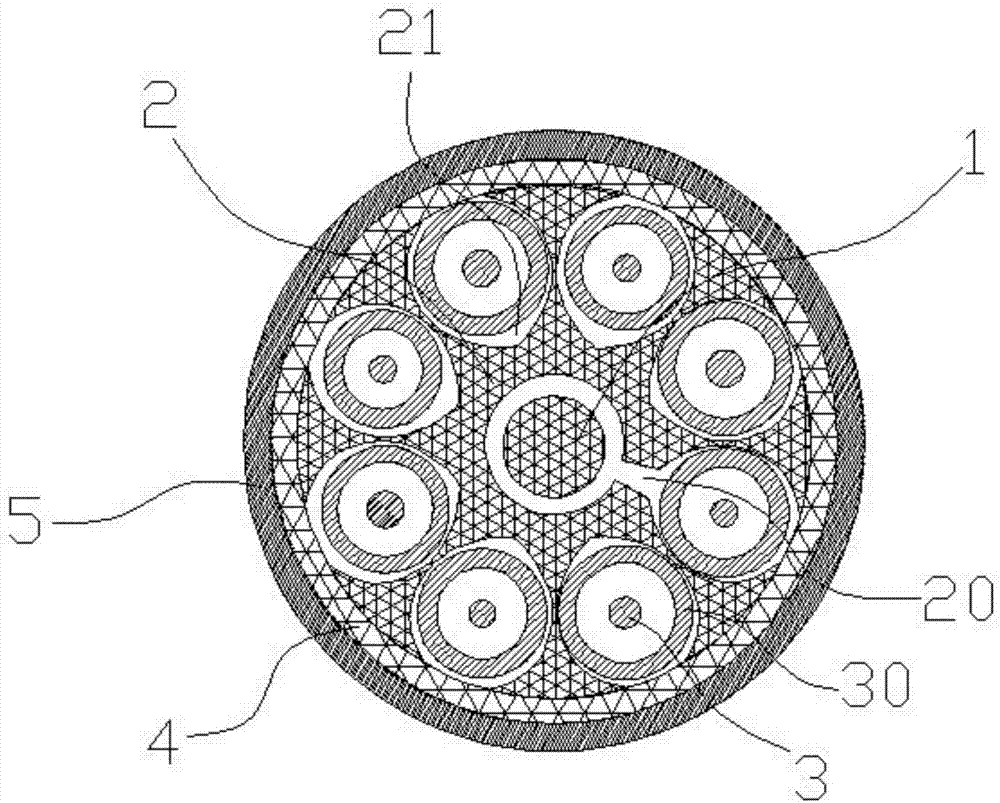

[0028] Embodiment 2: A tensile and torsion resistant fiber optic cable

[0029] See attached figure 2 , The rest is the same as the first embodiment, the difference is that the shape of the tensile and torsion component 2 is different, most of which are filled in the gap to play a stable role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com