Method for adsorbing and separating palladium, platinum and rhodium through copolymer of aniline and 2-amino-6-methoxybenzoic acid

A methoxybenzoic acid, adsorption and separation technology, applied in the field of precious metal metallurgy, can solve the problems of small adsorption capacity of chemical grafted adsorbent, no industrial-scale application, low adsorbent selectivity, etc., and achieves low cost and high efficiency. It is beneficial to industrial enlargement and the effect of less corrosiveness of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

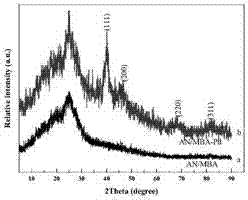

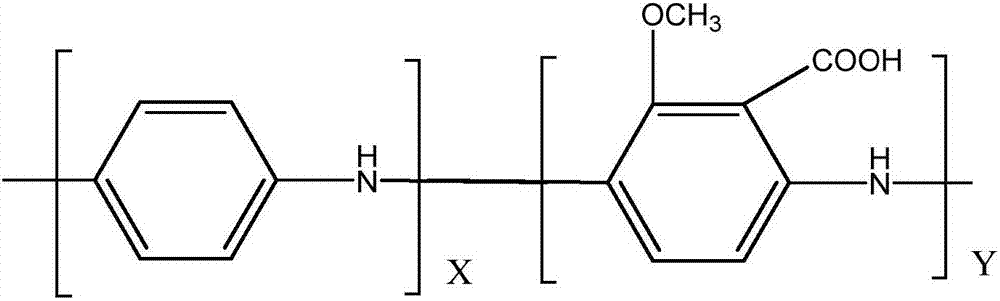

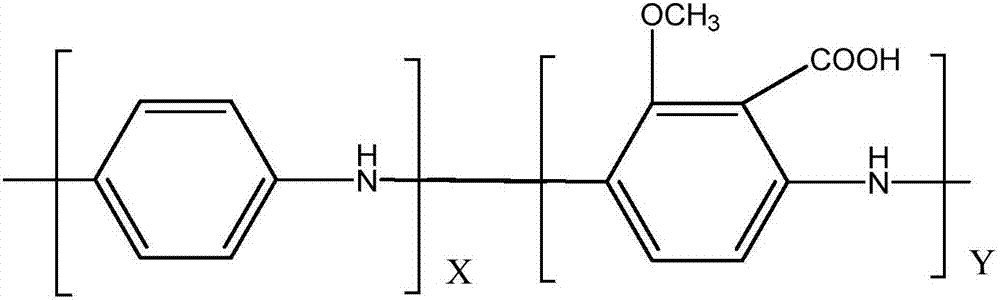

Image

Examples

Embodiment 1

[0039] Weigh 1.0g AN / MBA as the stationary phase, add it to 0.1mol / L C(HCl), 100mL Pd(II) solution with a concentration of 20g / L, shake for 15min, filter out the loaded AN / MBA; measure Pd For adsorption capacity, add the filtered AN / MBA loaded with Pd into 100mL 0.3mol / L thiourea solution, shake for 15min, filter out the AN / MBA in the desorption solution, wash the AN / MBA twice with distilled water, and adsorb again For the same Pd(II) solution, measure the maximum static adsorption capacity value for six cycles.

[0040] Advantage of the present invention, can find out from above-mentioned experiment, the measurement result of six cycles maximum static adsorption capacity is as shown in table 1:

[0041] Table 1. Determination of the maximum static adsorption capacity of Pd(II) six cycles

[0042] Cycles

[0043] It can be seen from Table 1 that after 6 cycles of use, the maximum static adsorption capacity of AN / MBA to Pd(II) has not decreased significantly, and th...

Embodiment 2

[0045] Weigh 1.0g AN / MBA as the stationary phase, add it to 0.1mol / L C(HCl) and 100mL Pt(IV) solution with a concentration of 10.0g / L, shake for 15min, filter out the loaded AN / MBA; measure Pt adsorption capacity, add the filtered Pt-loaded AN / MBA to 100mL pure water, shake for 10min, filter out the AN / MBA in the desorption solution, and absorb the same Pt(IV) solution again, and measure the maximum static state of 6 cycles Adsorption capacity value.

[0046] Advantage of the present invention, can find out from above-mentioned experiment, the measurement result of six cycles maximum static adsorption capacity is as shown in table 2:

[0047] Table 2. Determination of the maximum static adsorption capacity of Pt(IV) six cycles

[0048] Cycles

[0049] It can be seen from Table 2 that after six cycles of use, the maximum static adsorption capacity of AN / MBA to Pt(IV) has not decreased significantly, and the adsorption of AN / MBA to Pt(IV) has high stability and can b...

Embodiment 3

[0051] 1. Weigh 1.0g AN / MBA as stationary phase and add it to 0.1mol / L C(HCl) containing Pd, Pt and Rh in 100mL mixed material liquid. The content of Pd, Pt and Rh in the mixed material liquid Both were 10mg / L, shaken for 10min, and the loaded AN / MBA was filtered out; the contents of Pd, Pt and Rh in the filtrate were measured, and the recovery rate of Rh was calculated (see Table 3 for specific data).

[0052] 2. Add the AN / MBA loaded with Pd and Pt filtered out into 100mL pure water, shake for 5min, and filter out the AN / MBA in the desorption solution. Measure the content of Pd and Pt in the desorption solution, and calculate the recovery rate of Pt (see Table 3 for specific data).

[0053] 3. Add the AN / MBA desorbed with Pt into 100mL 0.1mol / L thiourea solution, shake for 10min, and filter out the AN / MBA in the desorbed solution. Determination of the content of Pd in the desorption liquid, calculate the recovery rate of Pd (see Table 3 for specific data).

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com