System for automatically controlling manipulator to move back to starting point

A control system and manipulator technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems that the manipulator cannot automatically return to the origin, affect the work efficiency of the manipulator, and affect the work of the manipulator, and achieve simple design methods, convenient operation, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

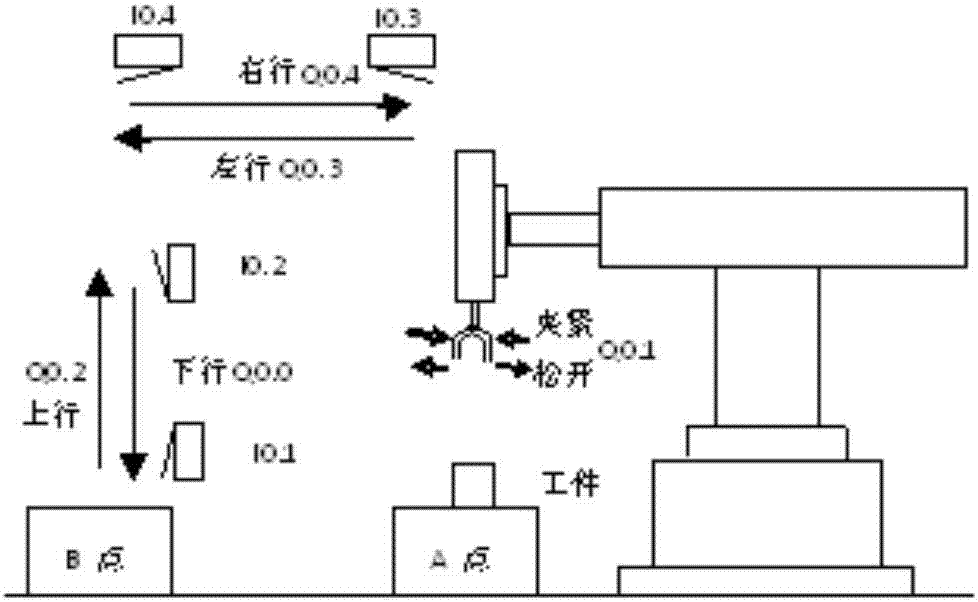

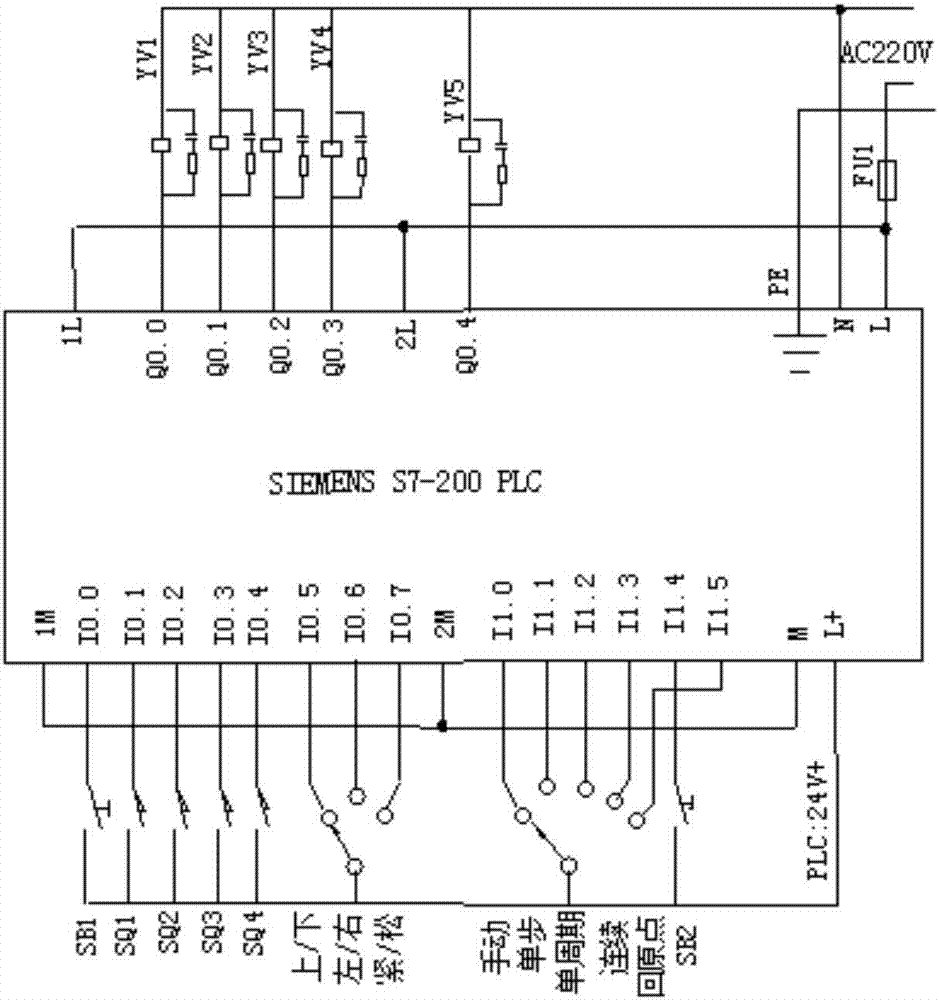

[0017] The automatic return-to-origin control system of the manipulator provided in the embodiment of the present invention is provided with a manipulator for clamping and releasing the workpiece;

[0018] Cylinder, installed at the back end of the manipulator, drives the manipulator to move;

[0019] Double-coil two-position solenoid valve, connected to the cylinder, moves the manipulator up / down and left / right;

[0020] The single-coil two-position solenoid valve is connected with the cylinder to clamp / relax the manipulator.

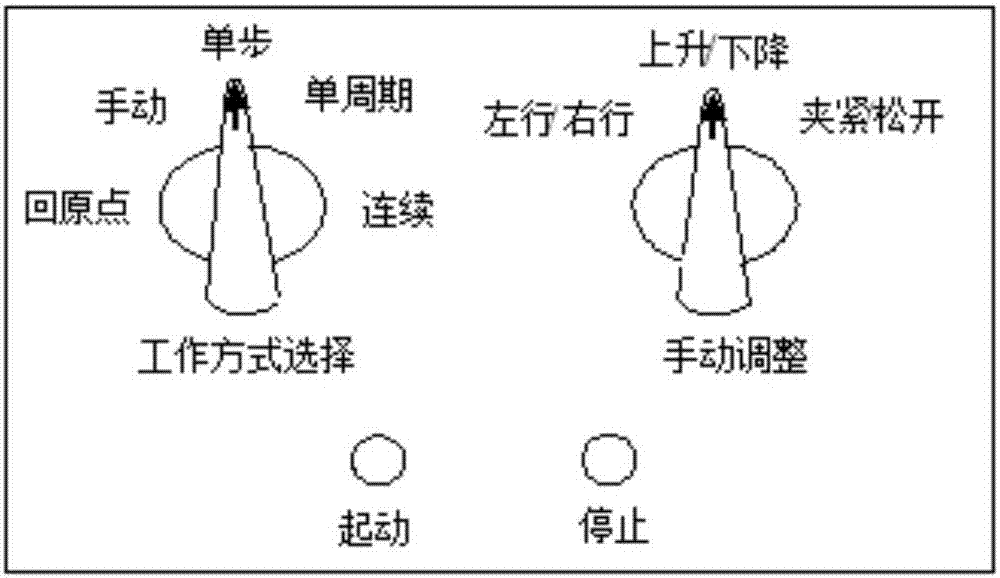

[0021] The PLC controller is respectively connected with the dual-coil two-position solenoid valve and the single-coil two-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com