Connecting part machining tool capable of reducing vibration

A connecting piece and tooling technology, applied in the field of auto parts, can solve problems affecting machining accuracy, flange scrapping, flange vibration, etc., and achieve the effects of improving machining accuracy, reducing vibration, and stabilizing drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

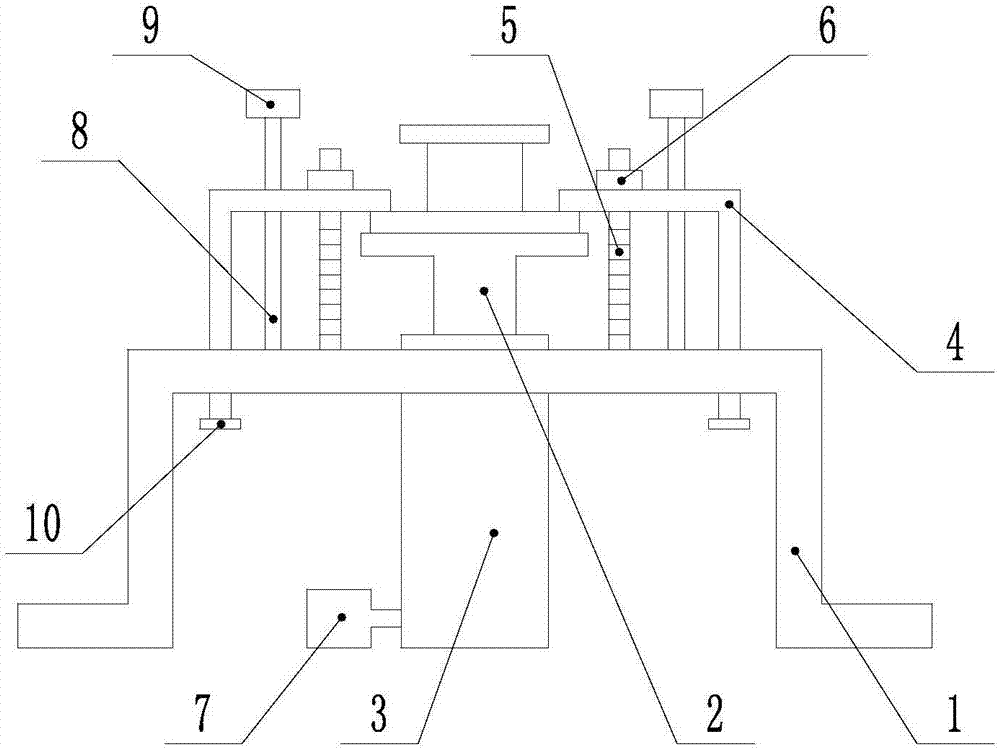

[0021] like figure 1 As shown, the connector processing tooling capable of reducing vibration of the present invention includes a base 1, on which a placing platform 2 is arranged, and the placing platform 2 is connected with a lifting mechanism 3, and the lifting mechanism 3 can drive the placing platform 2 to move, and the placing platform 2 Both sides are provided with hold-down device 4, and hold-down device 4 is provided with lead screw rod 5 through, and lead screw rod 5 is fixed on the base 1, and is provided with the nut 6 screwing with it on lead screw rod 5, and hold-down device 4 One end passes through the base 1 and can move along the axial direction of the lead screw 5, and the flange 11 is placed on the placement table 2, and the height of the placement table 2 can be adjusted through the lifting mechanism 3, so that the position of the flange 11 is more convenient for the drill bit to drill. hole, then move the compression device 4 along the lead screw 5, compre...

Embodiment 2

[0023] The present invention is based on embodiment 1, and the present invention is further described.

[0024] like figure 1 As shown, the present invention can reduce the vibration of the connecting piece processing tooling. The lifting mechanism 3 is a hydraulic lifting mechanism. The placement table 2 has played a supporting role, avoiding when drilling, the instability of the placement table 2 is easy to cause shaking or vibration, the stability of the placement table 2 is conducive to improving the precision of the drilling process, the lifting mechanism 3 is connected with the driving device 7, the driving device 7 drives the lifting of the lifting mechanism 3, and the drive device 7 can adopt a drive device commonly used in the prior art, such as a motor.

Embodiment 3

[0026] The present invention is based on embodiment 1, and the present invention is further described.

[0027] like figure 1 As shown, the present invention can reduce the vibration of the connecting piece processing tooling, the pressing device 4 is also provided with an auxiliary guide rod 8, the auxiliary guide rod 8 is parallel to the guide screw 5, and one end of the auxiliary guide rod 8 is fixed on the base 1 , the other end passes through the compression device 4, and the auxiliary guide rod plays a guiding role, making the movement of the compression device 4 more stable, avoiding the shaking of the compression device 4, and making the clamping effect of the compression device 4 on the flange better , the end of the auxiliary guide rod 8 away from the base 1 is provided with a limit block-9, the diameter of the limit block-9 is greater than the diameter of the auxiliary guide rod 8, and the effect of the limit block-9 is to prevent the auxiliary guide rod 8 from pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com