Method for welding compressor shell

A compressor shell and welding method technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as too thin plate thickness, small shell diameter, and difficult welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

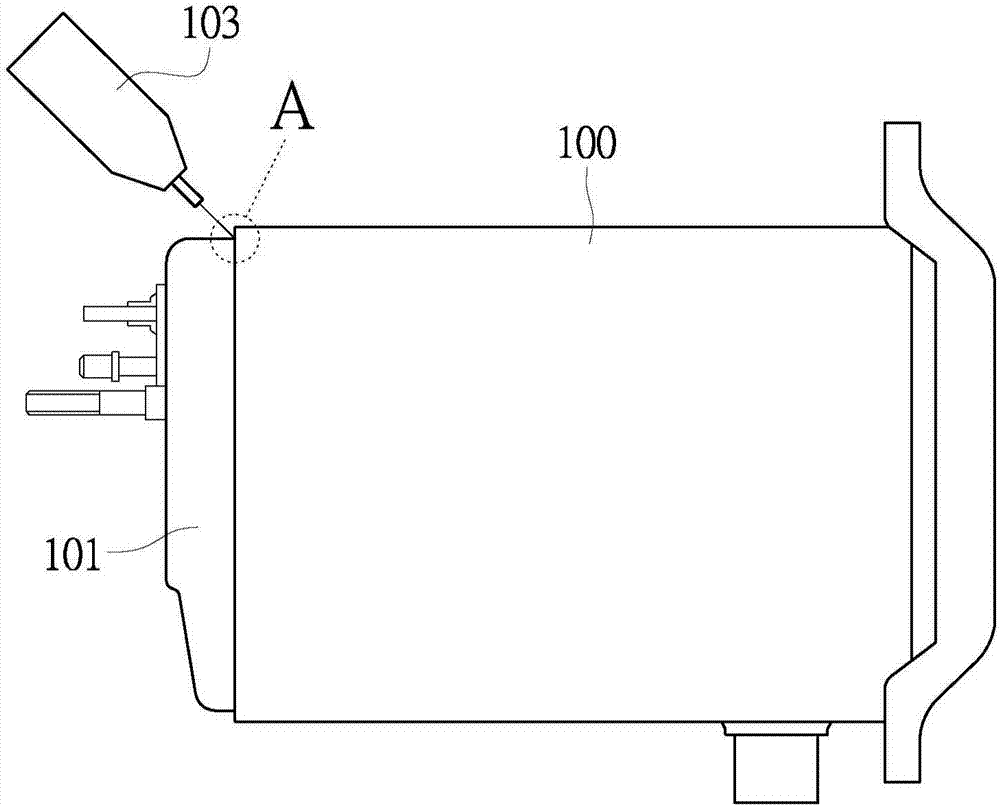

[0029] see Figure 5 , the present invention provides a welding method for a compressor shell, in particular relates to a welding method for a main shell of a compressor and a top cover and a bottom cover. The size of the compressor shell is not limited and can be applied to various sizes The compressor housing, the welding method of the compressor housing includes the following steps:

[0030] First, the cover body 2 of a compressor is lapped on one end of the main casing 1 (such as Image 6 and Figure 7 shown), and as mentioned above, the size of the main housing 1 and the cover 2 is not limited. In this embodiment, the thickness of the plates of the main housing 1 and the cover 2 are all below 2.5 mm. The cover 2 It can be a top cover or a bottom cover, that is, both the top cover and the bottom cover of the compressor can be respectively welded to the main casing 1 by using the welding method of the present invention.

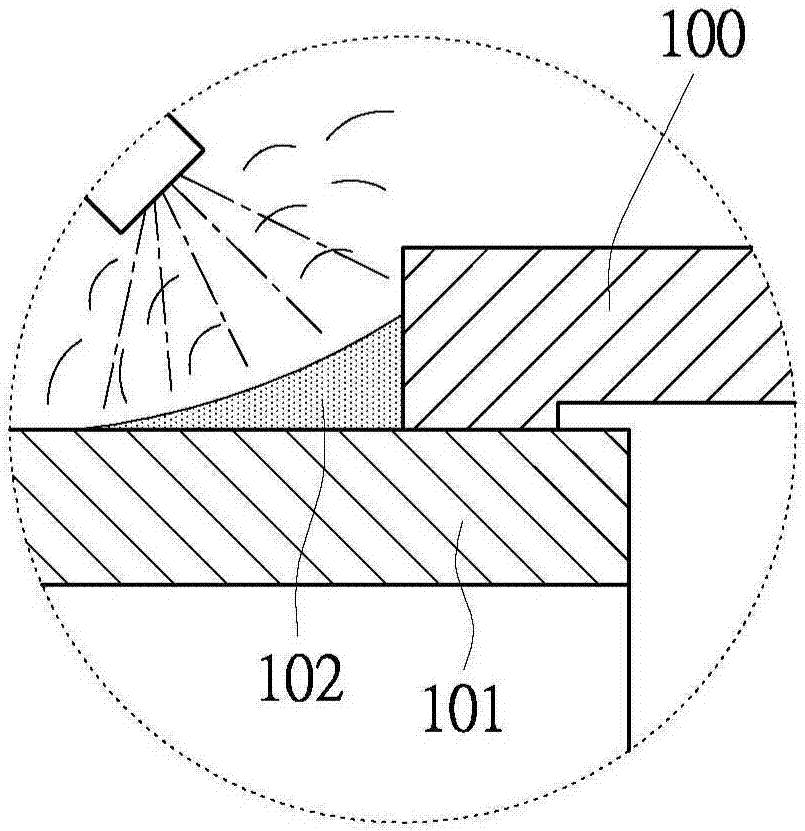

[0031] The main housing 1 and the cover 2 define ...

no. 2 example

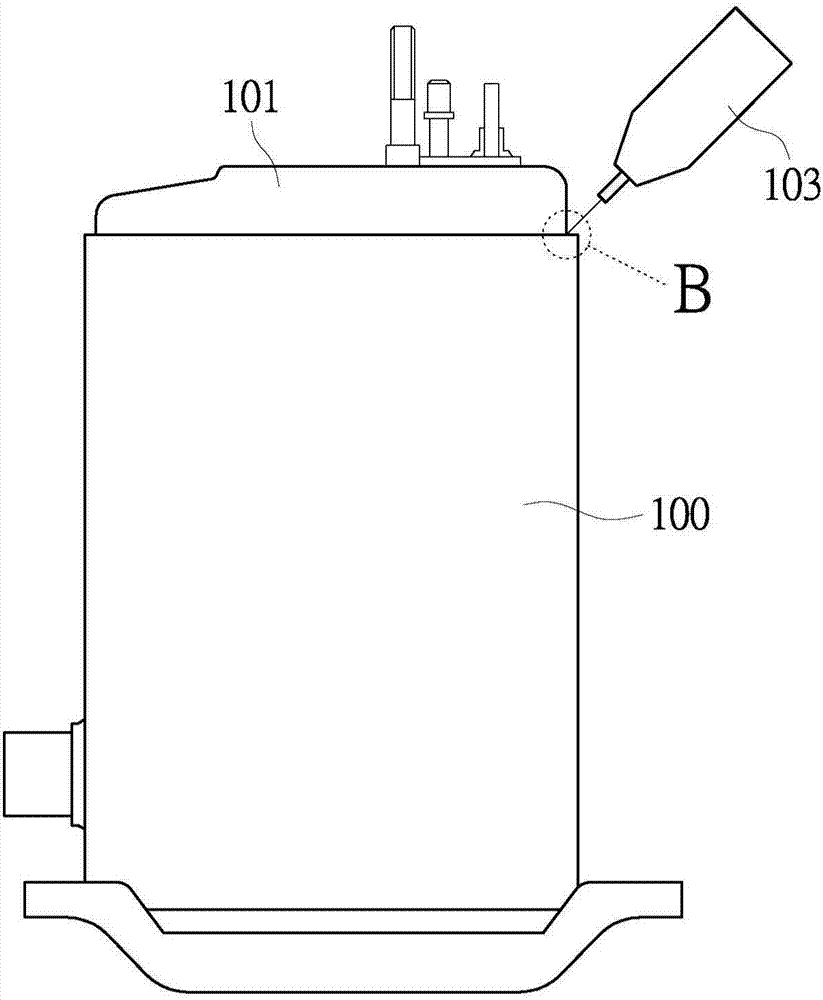

[0039] see Figure 8, in this embodiment, it can be further defined that one end of the main housing 1 and the cover 2 has a housing end surface 9 , and the housing end surface 9 can include the outer end surfaces of the cover 2 and the main housing 1 . The housing end face 9 can be a circular end face, and when the main housing 1 and the cover body 2 form an inclined setting, the housing end face 9 also forms an inclined state (such as Image 6 shown).

[0040] The central axis 3 intersects the housing end face 9 at a center point 91 of the end face. The housing end face 9 defines a transverse line 92 and a longitudinal line 93 . The transverse line 92 and the longitudinal line 93 intersect at the end face center point 91 . The transverse line 92 is parallel to the horizontal plane 4 and the longitudinal line 93 is perpendicular to the transverse line 92 . Define the outer diameter of the shell end face 9 as D, the distance between one end of the electrode 51 of the welding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com