Experimental loading device for shear-type energy-dissipating beams subjected to pure shear forces

A technology of loading device and energy-dissipating beam, which is applied in the direction of applying stable shear force to test the strength of materials, measuring devices, instruments, etc., which can solve the problem of time-consuming, uneconomical, and unable to realize the stress of shear-type energy-dissipating beams Status and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

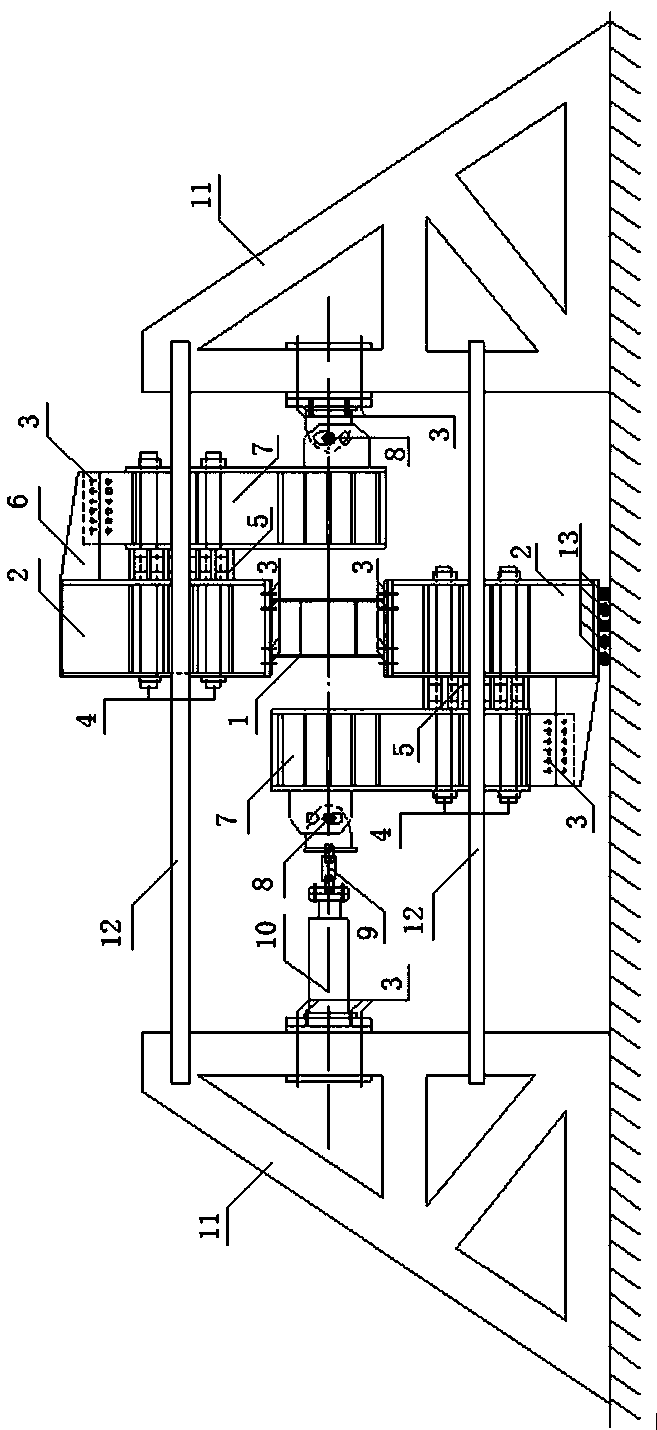

[0007] Such as figure 1 As shown, the technical solution adopted by the present invention to solve this technical problem is: arrange the entire loading device symmetrically with respect to the center of the shear-type energy-dissipating beam section, so as to ensure that the shear-type energy-dissipating beam section is subjected to pure shear force. The shear-type energy-dissipating beam section and the frame beam are designed separately, and the shear-type energy-dissipating beam section and the frame beam are connected by high-strength bolts, so that the independent loading of the shear-type energy-dissipating beam section can be realized, and shearing beam sections of different specifications can be replaced. Type energy-dissipating beam segment specimens.

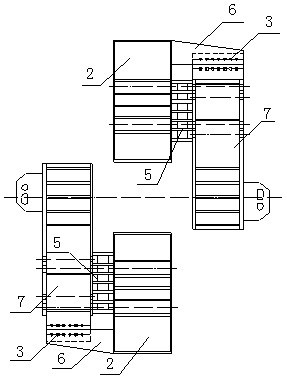

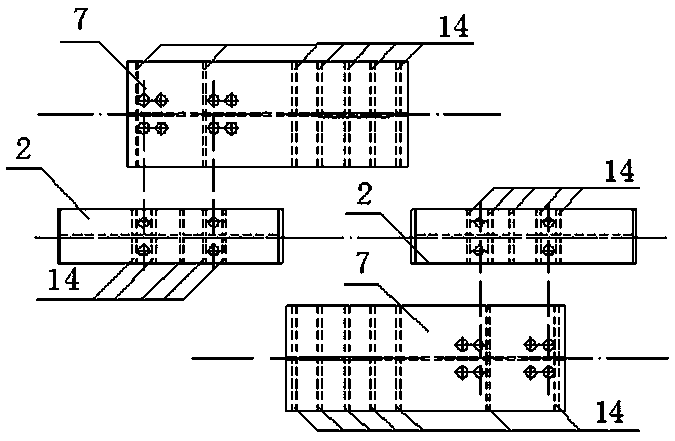

[0008] Such as figure 1 , figure 2 , image 3 As shown, the shear-type energy-dissipating beam section is subjected to pure shear test loading device. The whole test device includes four parts: the first part is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com