Synthesized bearing fault simulation test bed

A fault simulation and test bench technology, applied in mechanical bearing testing, material inspection products, vibration measurement, etc., can solve problems affecting the accuracy of state monitoring and fault diagnosis analysis, and information acquisition is not synchronized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

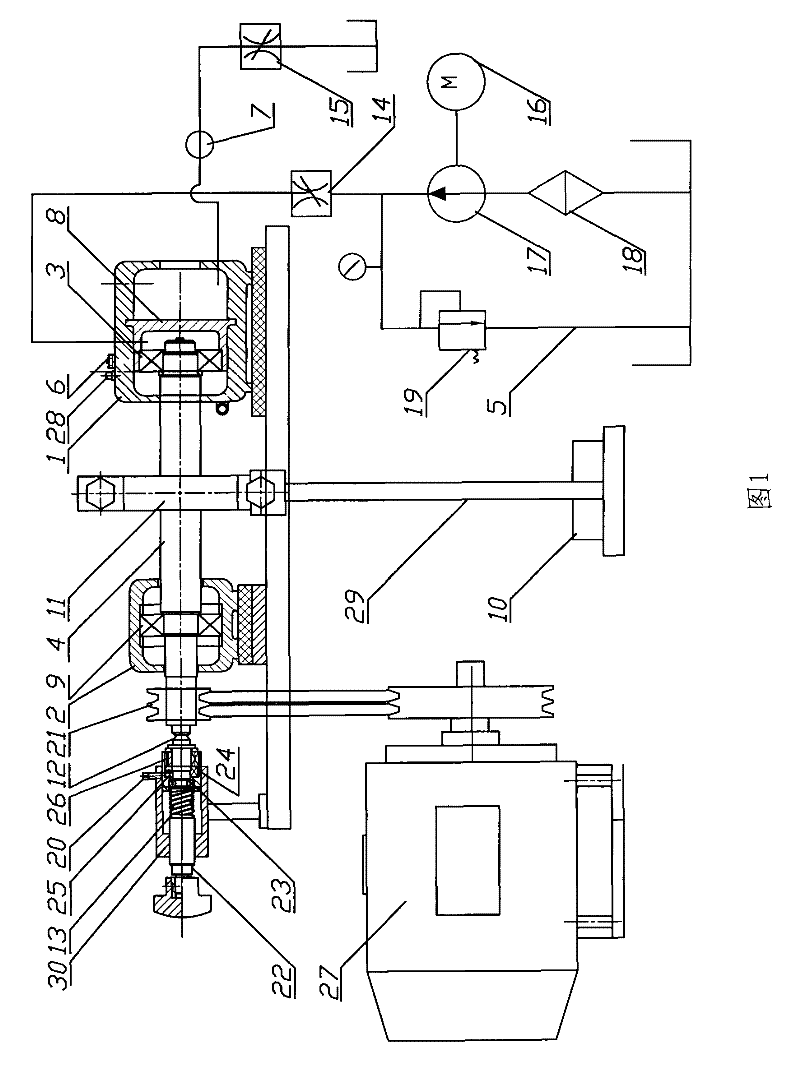

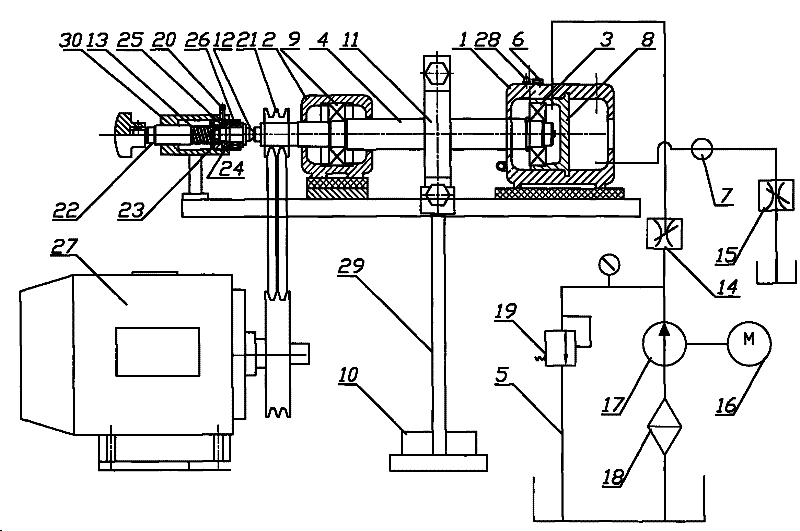

[0015] As shown in Figure 1, a comprehensive bearing failure simulation test bench, the experimental bearing 3 is installed in the removable bearing seat 1 through the bearing fixture 8, the removable bearing seat 1 is provided with a vibration sensor 6, and the removable bearing seat 1 Connected with the experimental lubrication system 5, the oil outlet pipe of the experimental lubrication system 5 is provided with an oil pipe sampling valve 7, a fixed bearing seat 2 is installed in the opposite direction of the removable bearing seat 1, and the supporting shaft 4 is installed on the removable bearing seat 1 and the fixed bearing seat 1. Between the bearing housings 2, a radial loading device 29 is installed in the middle of the supporting shaft 4, and an axial loading device 30 is installed at one end of the supporting shaft 4, and the supporting shaft 4 is connected with the prime mover 27 through a transmission mechanism 21.

[0016] The upper and lower parts of the removab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com