Railway passenger car bearing temperature detection method and digital/analog integrated temperature sensor

A technology of temperature sensor and bearing temperature, which is applied in the direction of railway vehicle shape measuring device, railway car body parts, temperature measurement of moving solids, etc. It can solve the problems of decreased sealing performance, water ingress, and narrow temperature measurement range of digital sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

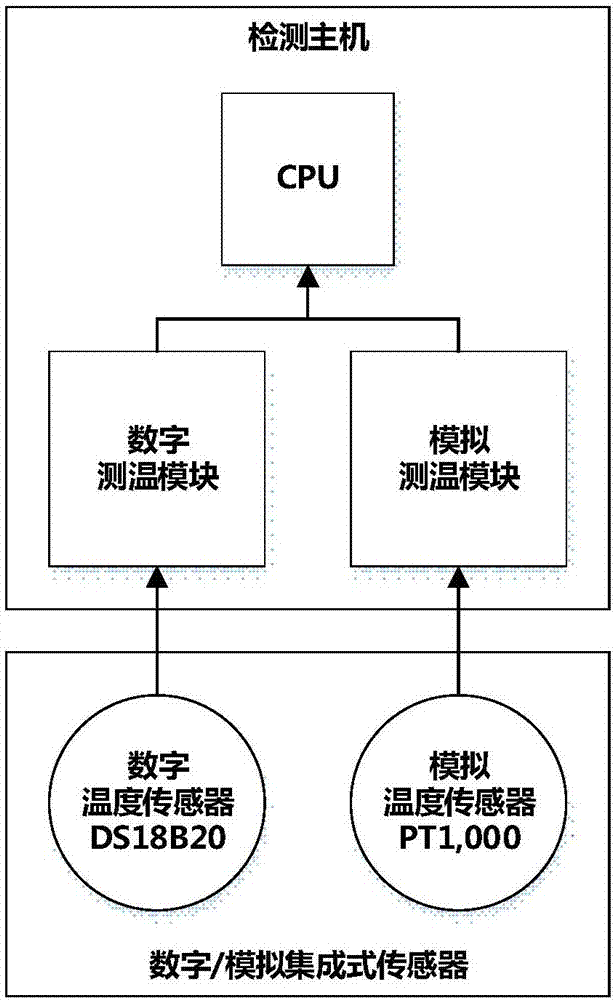

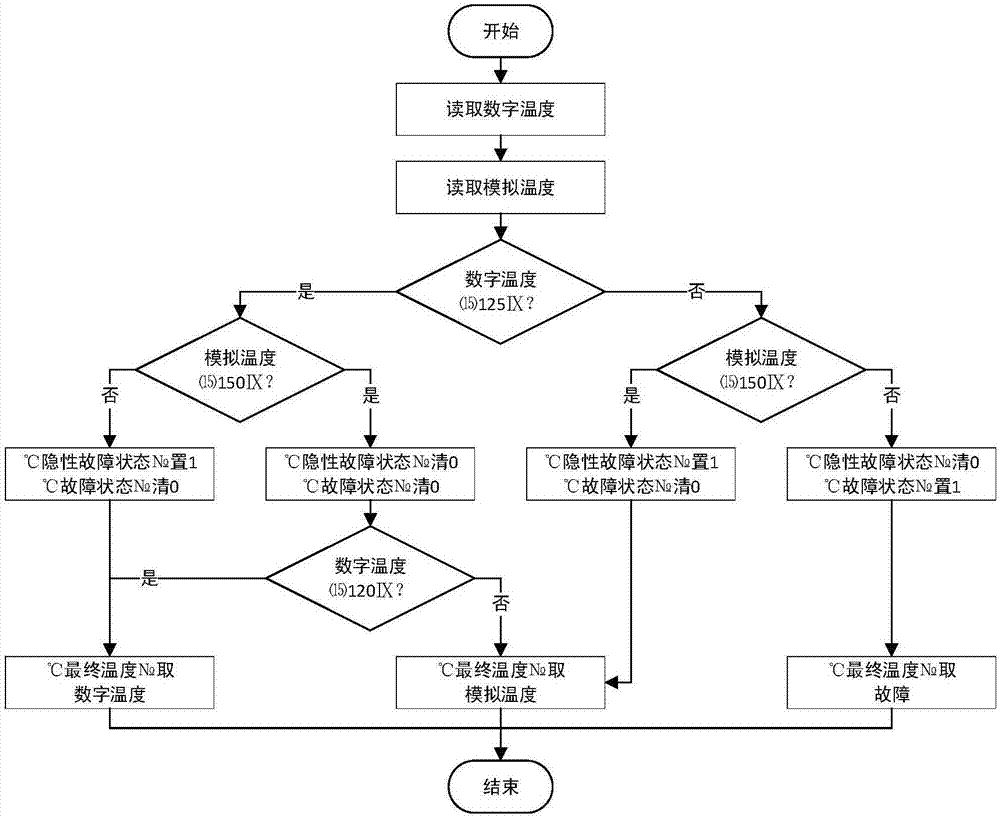

[0033] A temperature detection method. When the train is running, the axle box generates frictional heat, and the heat is conducted to the sensor probe. The sensor probe integrates digital and analog temperature measuring chips. The two temperature measuring chips simultaneously detect the temperature of the axle box and pass the temperature signal through The transmission line is sent to the detection host, and the detection host receives two temperature signals in sequence, makes independent judgments on the two signals and summarizes them, intelligently selects the two temperatures according to the temperature selection conditions, and finally selects one temperature for display, analysis and other follow-up processing ;

[0034] ① Independent judgment of temperature: When the detection host obtains a new temperature measurement result (temperature or fault), it should not be used immediately. Because after the axle temperature system is put into operation, the complexity a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com