Inspection robot system's vibration measurement control method

An inspection robot and control method technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of automatic inspection and vibration measurement of equipment, and achieve simple and easy testing process, accurate data, The effect of avoiding security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

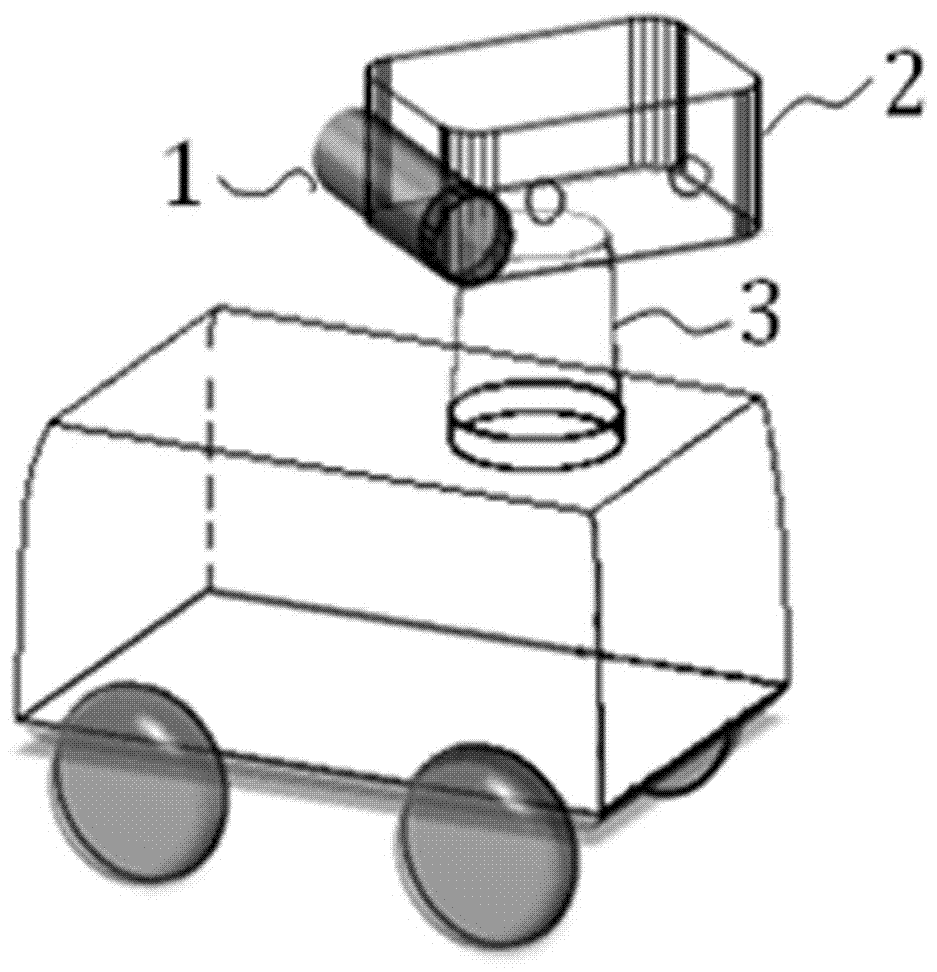

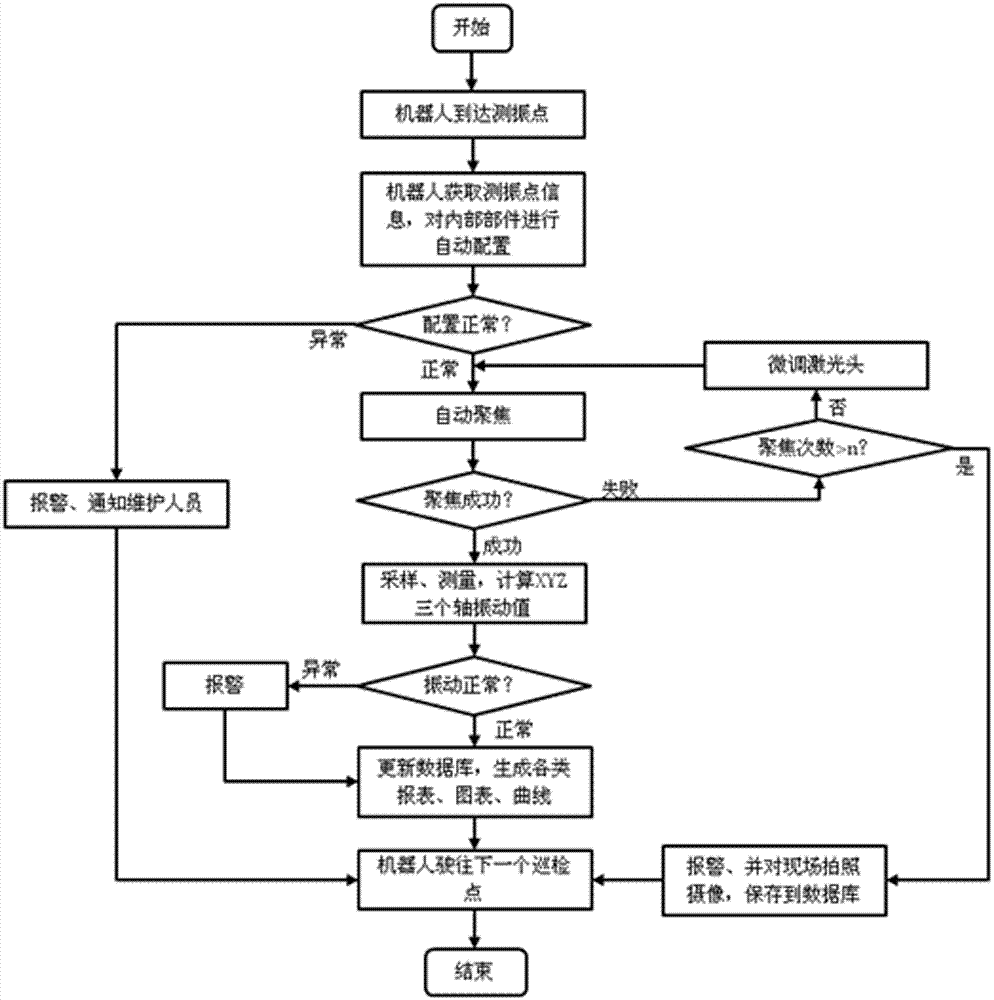

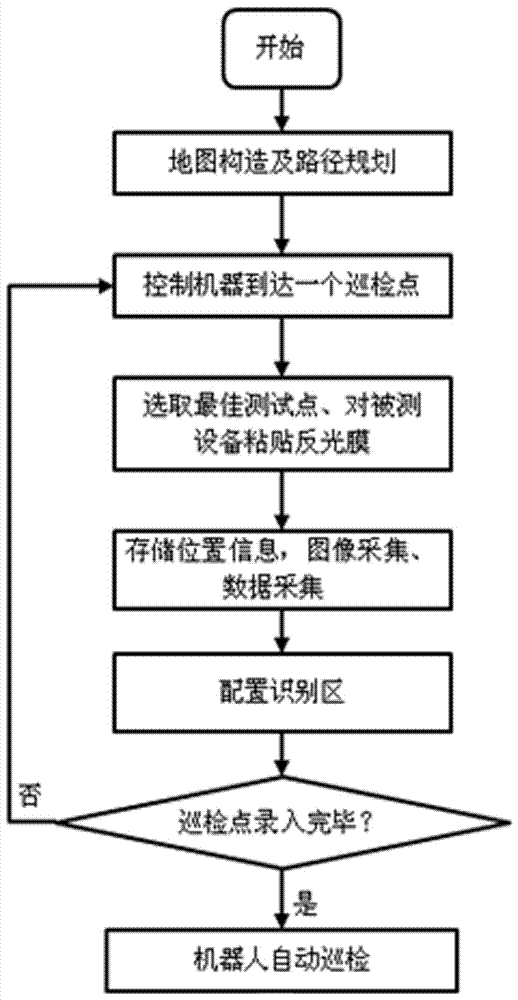

[0031] The invention proposes a vibration measurement control method for a patrol robot system. The patrol robot system includes: a patrol robot and a background system for data interaction with the patrol robot. Such as figure 1 As shown, in this embodiment, the inspection robot includes: a walking device, a pan platform 3, a vibration measuring laser head 1, a camera device 2 and a controller. The walking device is shaped like a trolley, and consists of a main body and four The drive wheel is formed, the pan-tilt 3 is installed on the main body of the walking device, the vibration measurement laser head 1 and the camera device 2 are installed on the pan-tilt 3, and the pan-tilt 3 can adjust the orientation and inclination of the vibration measurement laser head 1 and the camera device 2 Angle, etc., the controller performs data interaction with the background system through the wireless communication network, and the walking device, pan / tilt, vibration measuring laser head a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com