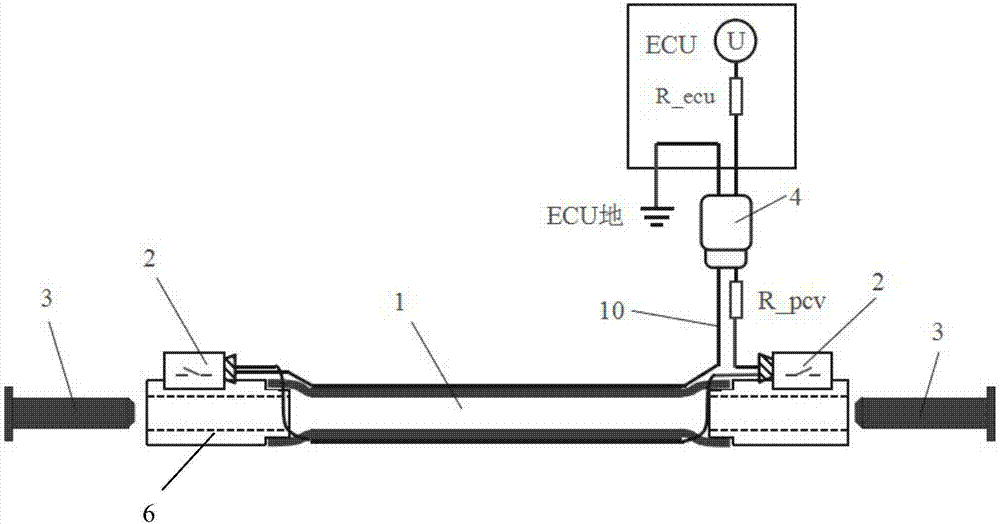

Pipeline disconnection detection system based on conducting loop mechanism

A detection system and conductive circuit technology, applied in the direction of engine measuring devices, pipe components, pipe joints, etc., can solve the problems of cumbersome installation, easy problems, and no diagnostic system, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

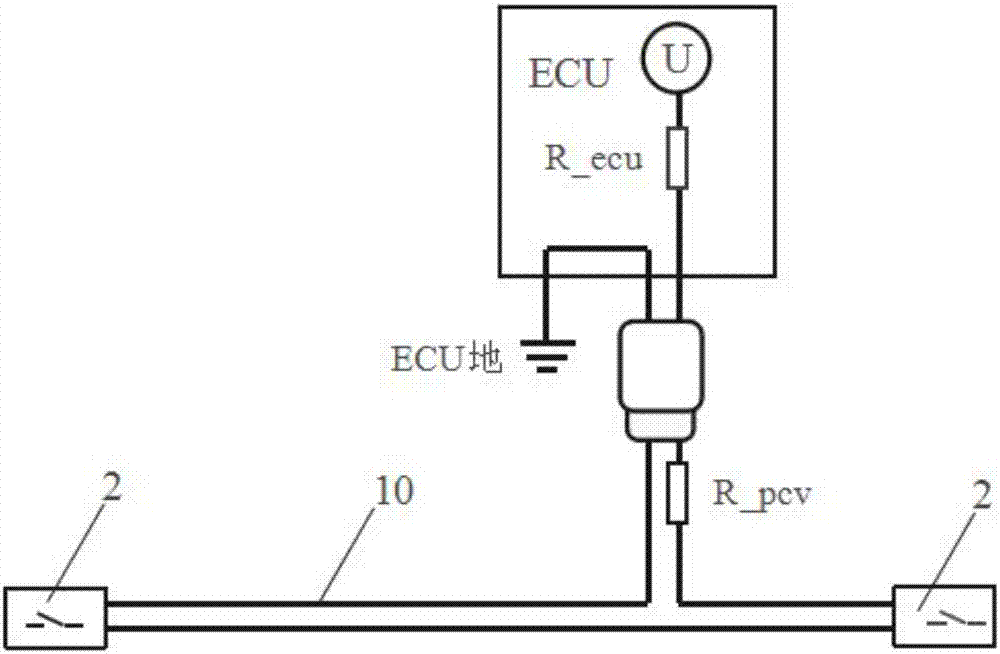

Embodiment 1

[0049] Along with the growth of service time, the insulating layer of the circuit surface that connects ECU unit in disconnection detection circuit 10 is corroded or wears and causes to contact with other automobile metal parts, may produce the positive pole of disconnection detection circuit 10 and produce grounding (being power terminal ground), we call it a short circuit to ground. If the upper resistor architecture is used inside the ECU, such as image 3 and 4 When the crankcase ventilation pipe joint is connected to the positive conductive wire of the ECU unit and the ground is short-circuited, as shown Figure 6 As shown, the ECU unit detects that the disconnection detection line voltage U_pcv is close to 0V. If there is no resistance R_pcv in the detection circuit 10, the resistance of the conductive wire inside the crankcase ventilation pipeline is almost zero (it can be regarded as R_pcv≈0), and the voltage of U_pcv is close to 0V; The open detection circuit 10 is...

Embodiment 2

[0052] As the use time increases, the insulating layer on the surface of the disconnection detection circuit 10 is corroded or worn, and the negative pole of the disconnection detection circuit 10 may be connected to the power supply, which is called a short circuit to the power supply. If the lower resistor architecture is used inside the ECU unit, such as Figure 5 As shown, when the crankcase ventilation pipe joint is connected to the negative conductive wire of the ECU and the power supply is short-circuited, as shown in Figure 8 As shown, the ECU detects the disconnection detection circuit voltage U_pcv'=U (the input voltage of the ECU unit is assumed to be U); if there is no resistance R_pcv' in the detection circuit 10, the resistance of the conductive wire inside the crankcase ventilation pipeline is almost zero ( It can be regarded as R_pcv'≈0V), and the voltage of U_pcv' is close to U. Therefore, in the case of a short circuit between the negative electrode and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com