Electromagnetic heating tyre mould

A technology of tire molds and electromagnetic heating devices, which is applied to tires, household appliances, and other household appliances. It can solve problems such as inability to accurately control temperature, affect tire quality, and insufficient thermal stability, so as to shorten vulcanization time and save energy. , Convenient and precise control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

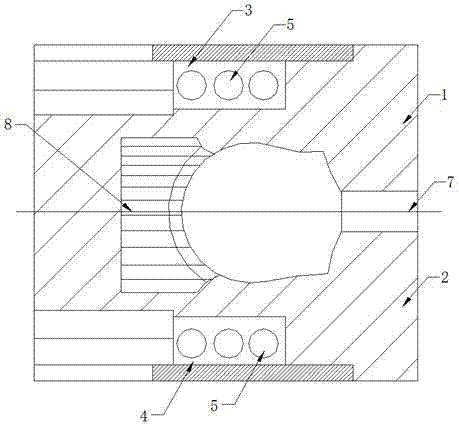

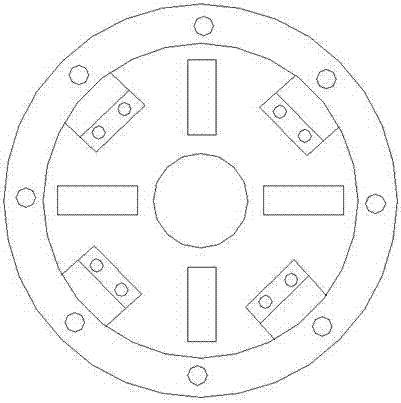

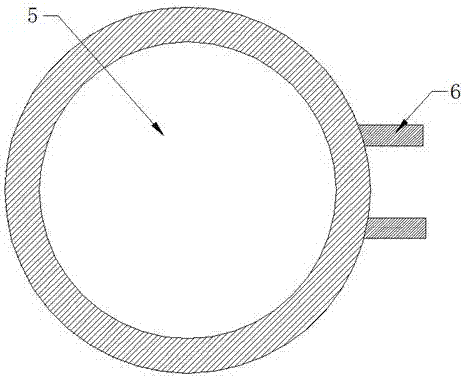

[0019] like Figure 1-3 As shown, the present invention provides an electromagnetic heating tire mold, comprising an upper template 1 and a lower template 2, the upper template 1 and the lower template 2 jointly form a closed integral structure, the upper template 1 is provided with an upper side plate 3, and the lower template 2 A lower side plate 4 is provided, and the upper side plate 3 and the lower side plate 4 are both provided with an electromagnetic heating device 5 , and one side of the electromagnetic heating device 5 is provided with a power interface 6 .

[0020] Further, a seal 7 is provided between the upper template 1 and the lower template 2, which can effectively improve the sealing performance between the upper template 1 and the lower template 2, so that the upper template 1 and the lower template 2 can be better combined.

[0021] The inner sides of the upper template 1 and the lower template 2 are provided with pattern bushings 8, which provide the pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com